Co2FeAl-LDH, preparation method of Co2FeAl-LDH and method for degrading pollutants

A co2feal-ldh, sewage technology, applied in water pollutants, water/sewage treatment, chemical instruments and methods, etc., can solve problems such as difficulty in drug removal, and achieve the effects of easy recovery, good stability and good reusability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The present invention provides a novel Co 2 The preparation method of FeAl-LDH comprises the following steps:

[0033] Dissolving cobalt nitrate, iron nitrate, aluminum nitrate and urea in water to obtain a homogeneous solution;

[0034] React the homogeneous solution at 105-115°C for 22-26 hours to obtain Co 2 FeAl-LDH nanosheets.

[0035] The method provided by the invention can prepare Co 2 FeAl-LDH, and it can be used as a catalyst to efficiently activate persulfate to generate strongly oxidized sulfate radicals, and rapidly catalyze the degradation of pollutants in sewage, such as: methoxazole, ciprofloxacin and tetracycline. The process is simple, highly maneuverable, and does not require additional capacity. Co prepared by the method provided by the invention 2 FeAl-LDH is a heterogeneous catalyst, easy to recover, and has good stability and good reusability.

[0036] In the present invention, the nitrate of cobalt is preferably selected from Co(NO3 ) 2 ·6...

Embodiment 1

[0051] co 2 FeAl-LDH material activates persulfate to degrade sulfamethoxazole in water.

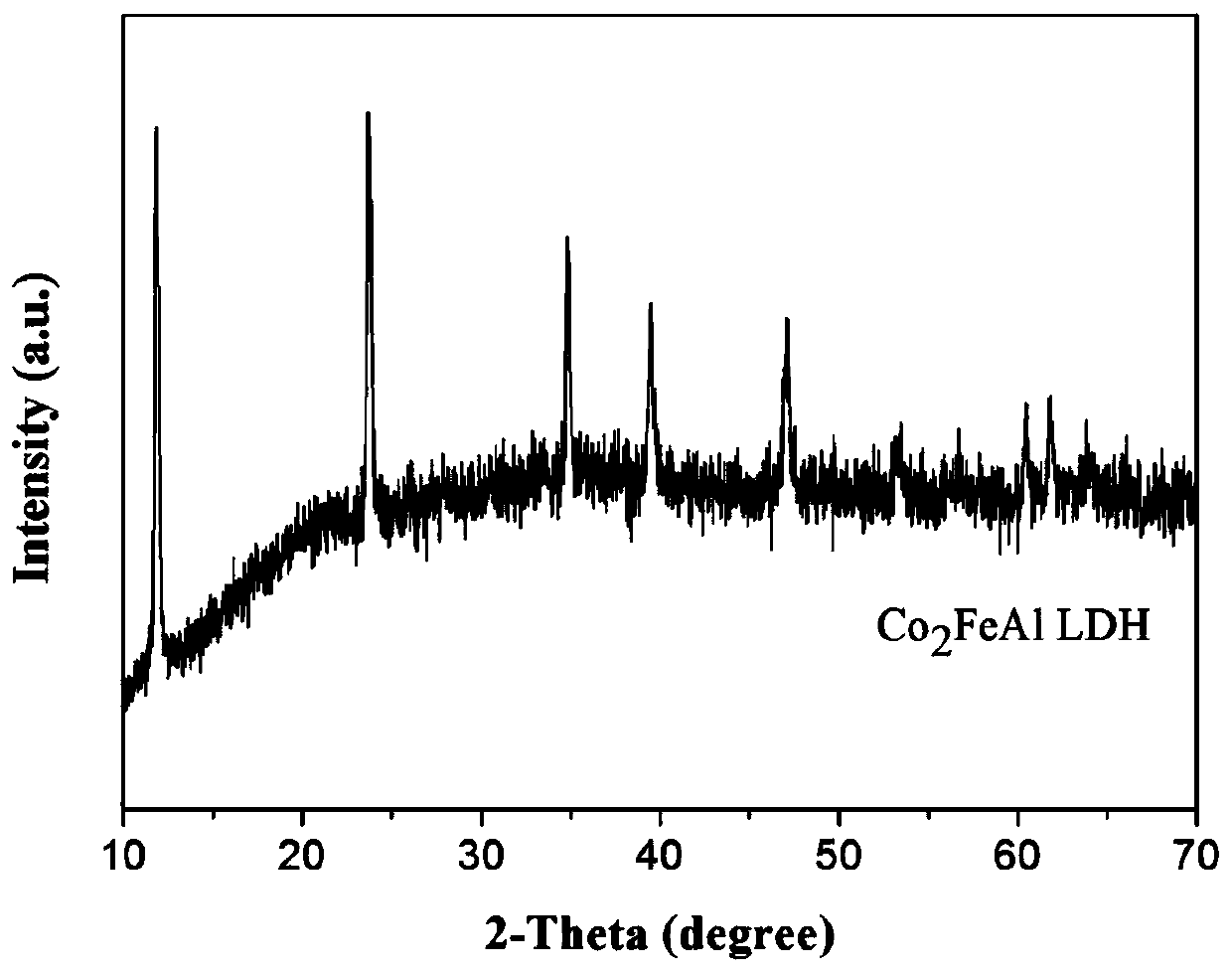

[0052] (1)Co 2 Preparation of FeAl-LDH material: 0.01mol of Co(NO 3 ) 2 ·6H 2 O, 0.005mol Fe(NO 3 ) 3 ·6H 2 O and 0.005mol of Al(NO 3 ) 3 9H 2 O and 0.1 mol of urea were dissolved in 100 mL of deionized water to obtain a homogeneous solution. After the oil bath was heated to 110 °C and stirred continuously for 24 h, after cooling to room temperature, the obtained solid was filtered and washed three times with deionized water, and finally vacuum Dry to obtain the catalyst Co 2 FeAl-LDH nanosheets. figure 1 Co prepared for Example 1 of the present invention 2 X-ray crystal diffraction pattern (XRD) of FeAl-LDH; figure 2 Co prepared for Example 1 of the present invention 2 Scanning electron microscope (SEM) of FeAl-LDH; image 3 Co prepared for Example 1 of the present invention 2 Transmission electron microscopy (TEM) of FeAl-LDH.

[0053] (2) Prepare a 10 mg / L sulfametho...

Embodiment 2

[0058] co 2 FeAl-LDH material activates persulfate to degrade ciprofloxacin in water.

[0059] (1)Co 2 Preparation of FeAl-LDH material: 0.01mol of Co(NO 3 ) 2 ·6H 2 O, 0.005mol Fe(NO 3 ) 3 ·6H 2 O and 0.005mol of Al(NO 3 ) 3 9H 2 O and 0.1 mol of urea were dissolved in 100 mL of deionized water to obtain a homogeneous solution. After the oil bath was heated to 110 °C and stirred continuously for 24 h, after cooling to room temperature, the obtained solid was filtered and washed three times with deionized water, and finally vacuum Dry to obtain the catalyst Co 2 FeAl-LDH nanosheets.

[0060] (2) Prepare a ciprofloxacin solution of 10 mg / L for subsequent use.

[0061] (3) Take 50 mL of ciprofloxacin solution with a concentration of 10 mg / L in a test tube, add 0.003 g of catalyzer, 0.2 mmol / L of persulfate, and 0.003 g of catalyzer at the same time to add 0.2 mmol / L of persulfate, stirred, fixed-point sampling analysis.

[0062] Figure 5 Co prepared for the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com