Method for preparing acetate by using clay-based solid acid

An acetate and clay-based technology, applied in the field of clay-based solid acid to prepare acetate, achieves high catalytic efficiency, simple preparation and operation, and reduces equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

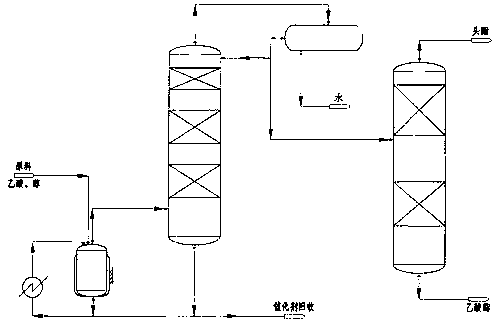

Image

Examples

Embodiment 1

[0011] Preparation of clay-based solid acid catalyst: Stir and disperse 1kg halloysite and 20kg absolute ethanol in ultrasonic for 1min, then add 20g of tin tetrachloride, continue to disperse under ultrasonic stirring for 5min, drop ammonia water, adjust the pH of the system to 6, Then aged at 70°C for 8h. After drying the aged colloid at 80°C, it was acidified and impregnated with 2M sulfuric acid for 1 hour, and finally the obtained catalyst was calcined in a muffle furnace at 500°C for 3 hours.

[0012] Clay-based solid acid catalyst catalyzed synthesis of propyl acetate: 1 kg of clay-based solid acid catalyst was added to a heated and stirred reactor, and acetic acid and propanol were continuously added to the reactor at a molar ratio of 1:1 to make the reactor, the catalyst Maintain at about 8wt%, heat to 115°C for continuous reaction, the reaction product is separated and removed after azeotropic distillation in the esterification tower, and the crude product of propyl ...

Embodiment 2

[0015] Preparation of clay-based solid acid catalyst: Stir and disperse 1kg of halloysite and 35kg of absolute ethanol in ultrasonic for 5 minutes, then add 24g of tin tetrachloride, continue to disperse with ultrasonic stirring for 10min, add ammonia water dropwise, adjust the pH of the system to 6, Then aged at 70°C for 24h. After drying the aged colloid at 80°C, it was acidified and impregnated with 2M sulfuric acid for 2h, and finally the obtained catalyst was calcined in a muffle furnace at 600°C for 2h.

[0016] Clay-based solid acid catalyst catalyzed synthesis of butyl acetate: 1kg of catalyst was added to a heated and stirred reactor, and acetic acid and butanol were continuously added to the reactor at a molar ratio of 1:1 to keep the catalyst at 5wt% Heating to 120°C for continuous reaction, the reaction product is separated and removed from water after azeotropic distillation in the esterification tower, and the crude product of butyl acetate with a content of 95% ...

Embodiment 3

[0019] Preparation of clay-based solid acid catalyst: Stir and disperse 1kg of halloysite and 20kg of absolute ethanol in ultrasonic for 3 minutes, then add 24g of tin tetrachloride, continue to disperse with ultrasonic stirring for 10min, add ammonia water dropwise, adjust the pH of the system to 6, Then aged at 70°C for 24h. After drying the aged colloid at 80°C, it was acidified and impregnated with 2M sulfuric acid for 2h, and finally the obtained catalyst was calcined in a muffle furnace at 500°C for 2h.

[0020] Clay-based solid acid catalyst catalyzed synthesis of ethyl acetate: 1 kg of clay-based solid acid catalyst was added to a reactor with heating and stirring, and acetic acid and ethanol were continuously added to the reactor at a molar ratio of 1:1 to maintain the catalyst in the reactor at About 10wt%, heating to 110°C for continuous reaction, the reaction product is separated and removed after azeotropic distillation in the esterification tower, and the crude p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com