A kind of high molecular weight hydroxamated polyacrylamide emulsion and preparation method thereof

A technology of polyacrylamide and high molecular weight, which is applied in the field of high molecular weight hydroxamated polyacrylamide emulsion and its preparation, which can solve the problems of high reaction temperature, shorten the reaction time, improve the conversion rate of hydroxylamine, and prevent volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

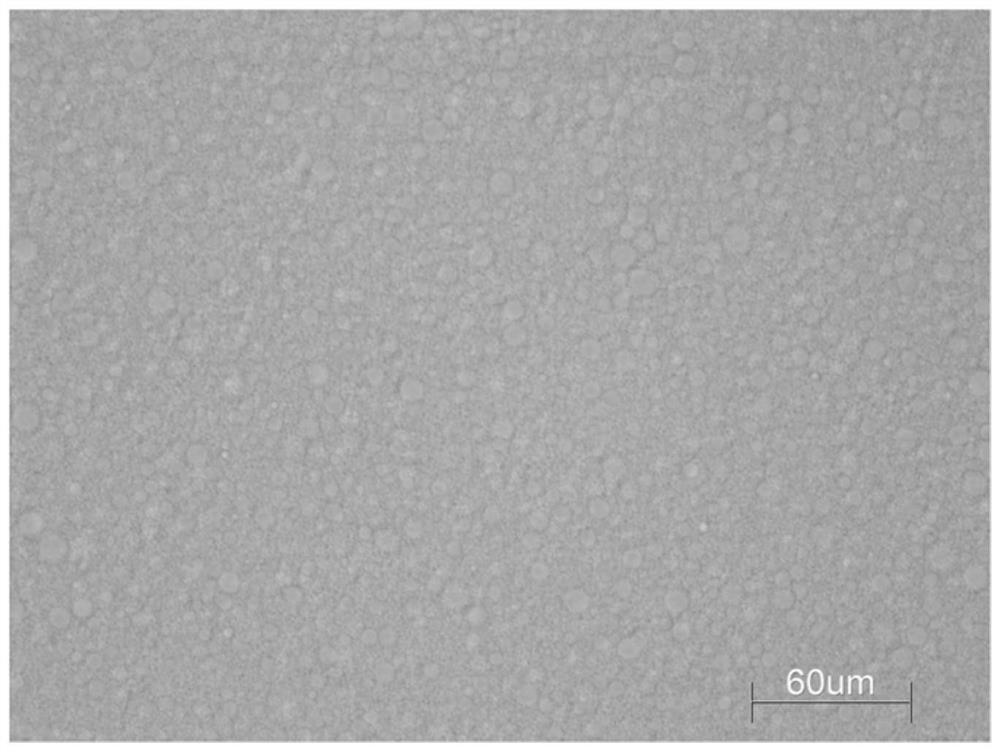

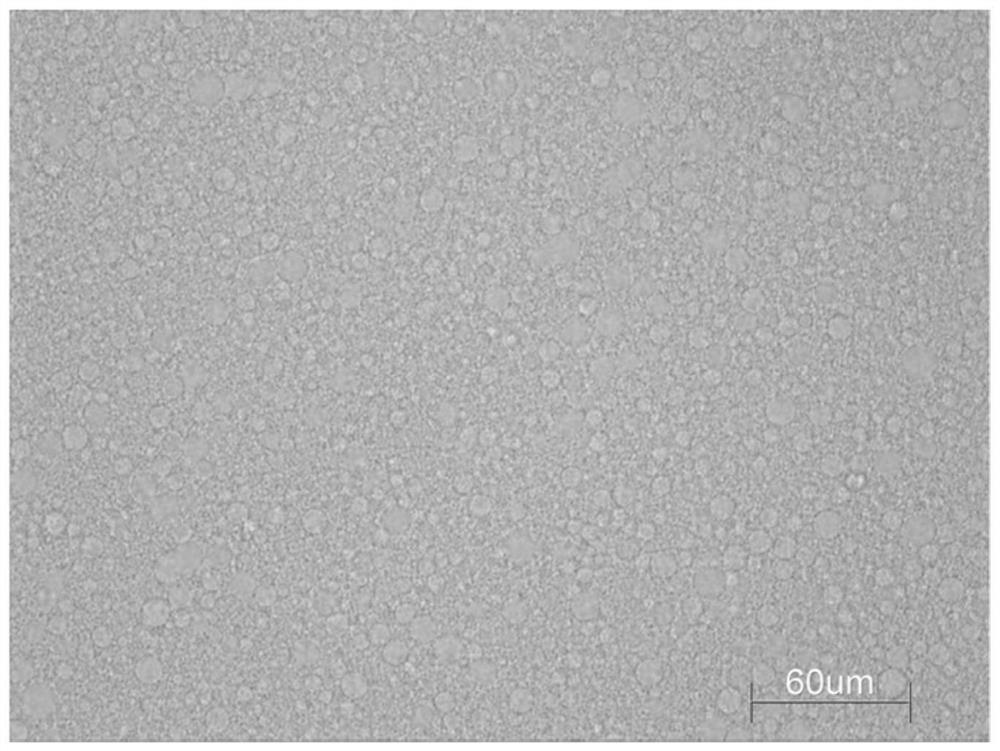

Image

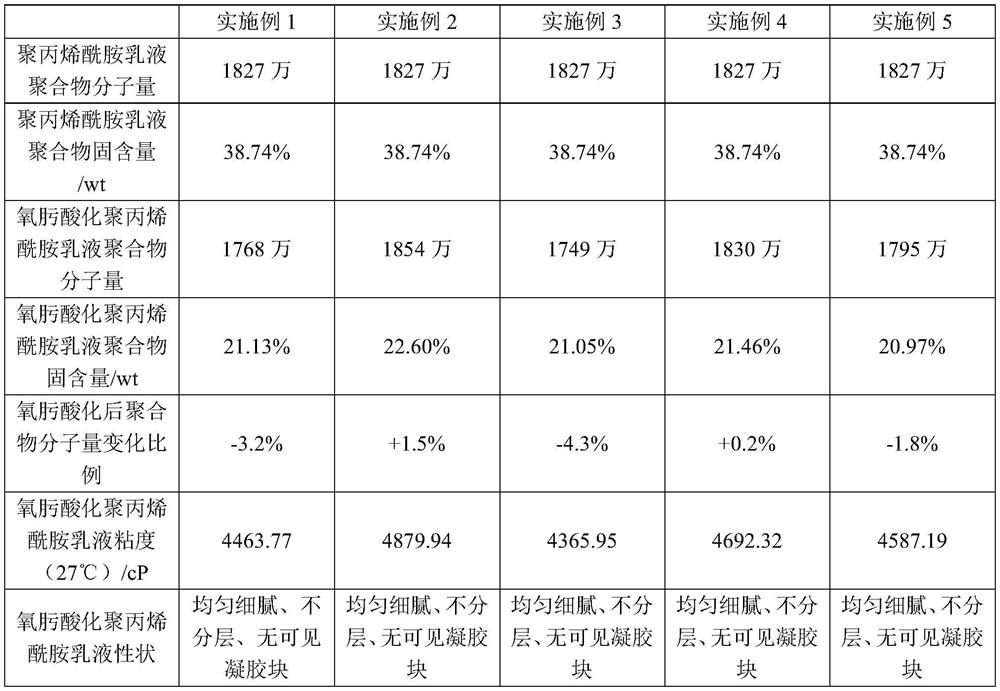

Examples

Embodiment 1

[0031] The preparation method of the high molecular weight oxyxime acidified polyacrylamide emulsion provided in the present embodiment is:

[0032] S1: Emulsion polymerization process

[0033] (1) Preparation of aqueous phase: under stirring, the monomer 2-acrylamide-2-methylpropanesulfonic acid (AMPS) is dissolved in deionized water to prepare a 50% (wt) aqueous solution, and then a monomer acrylic acid (AA) is added, and pH ≈8 (control temperature is not more than 20 ° C) is adjusted with 42% (wt) liquid alkali; and then monomer acrylamide (AM) and deionized water are added to form an aqueous solution with a monomer concentration of 50% (wt). The addition of the initiator sodium hypophosphite (SHP) to the aqueous solution initiates a prepolymerization reaction to form a comonomy aqueous phase. Among them, the molar ratio of AM, AA, AMPS, and SHP is 60:25:15:0.11.

[0034] (2) Preparation of oil phase: Under stirring, Span-80 (sorbitan fatty acid ester) and 6501 (coconut oil fat...

Embodiment 2

[0041] The preparation method of the high molecular weight oxyxime acidified polyacrylamide emulsion provided in the present embodiment is:

[0042] S1: Emulsion polymerization process

[0043] Same as Step 1 of Example S1.

[0044] S2: Oxime acidification process

[0045] (1) Preparation of the aqueous phase: with Step 1 of the Same Embodiment S2 (1).

[0046](2) Preparation of oil phase: According to the mass ratio of 13.5:1, the 120# solvent oil is mixed with 1802 (industrial ethoxylated fatty amine, EO=2), and the clarified oil phase is evenly stirred to obtain a clear oil phase.

[0047] (3) Oxime acidification reaction: according to the weight of the parts, the polyacrylamide emulsion prepared by 35 parts of step S1 is added to the stainless steel sandwich cylinder, 7 parts of the oil phase are added, dispersed for 10min and then added 18 parts of the aqueous phase after the oxoxime acidification reaction at 25 ~ 45 °C, and the reaction is obtained after 2.5h to obtain the o...

Embodiment 3

[0049] The preparation method of the high molecular weight oxyxime acidified polyacrylamide emulsion provided in the present embodiment is:

[0050] S1: Emulsion polymerization process

[0051] Same as Step 1 of Example S1.

[0052] S2: Oxime acidification process

[0053] (1) Preparation of the aqueous phase: with Step 1 of the Same Embodiment S2 (1).

[0054] (2) Preparation of oil phase: According to the mass ratio of 14:1, the 150# solvent oil is mixed with 1802 (industrial ethoxylated fatty amine, EO=2), and the clarified oil phase is stirred to obtain a clear oil phase.

[0055] (3) Oxyme acidification reaction: according to the weight of the parts, the 32 parts of the polyacrylamide emulsion prepared in step S1 was added to the stainless steel sandwich cylinder, 9 parts of the oil phase were added, and after dispersing for 10 minutes, 18 parts of the aqueous phase were added to the oxyme acidification reaction at 25 ~ 45 ° C, and the reaction was obtained after 2h to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com