Preparation method of leisure shoe sole material with anti-slip performance

A sole material and performance technology, applied in the field of footwear materials, can solve the problems of affecting comfort, general anti-slip performance, and easy slipping, etc., and achieve the effect of improved anti-slip performance, excellent anti-slip performance, and avoiding easy aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

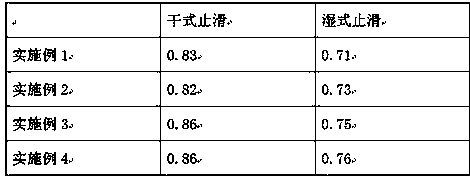

Examples

preparation example Construction

[0023] A kind of preparation method of leisure shoe sole material with anti-skid property, comprises the following steps:

[0024] (1) Heat the resistance furnace to 900-930°C, keep it warm for 3 minutes, then add carbon black to the resistance furnace, keep it warm for 5 minutes, then add zinc ingots, keep it warm for 12-16 minutes, and get carbon black composite zinc oxide whiskers, By adding carbon black composite zinc oxide whiskers to the natural rubber system, the mechanical and thermodynamic properties of natural rubber are improved through the dispersion or interfacial interaction of carbon black composite zinc oxide whiskers, carbon black composite zinc oxide whiskers and natural rubber The interaction between macromolecules can form a special double filling network, which can form a composite layer surface at the interface layer, which greatly improves the anti-slip performance of leisure shoe sole materials;

[0025] (2) Add halloysite to an ethanol solution that is...

Embodiment 1

[0040] The preparation method of the leisure shoe sole material with anti-slip performance of the present application comprises the following steps:

[0041] (1) Heat the resistance furnace to 900°C, keep it warm for 3 minutes, then add carbon black to the resistance furnace, keep it warm for 5 minutes, then add zinc ingots, keep it warm for 12 minutes, and get carbon black composite zinc oxide whiskers, the carbon black particle size is 800 mesh, the mass ratio of carbon black to zinc oxide in carbon black composite zinc oxide whiskers is 10:1;

[0042] (2) Add halloysite to a 35% ethanol solution with a mass fraction 6 times its mass, stir evenly, and then add sodium silicate and stearic acid, the mass ratio of sodium silicate and stearic acid is 1: 3. Add sodium silicate in an amount of 2.8% of the mass of ethanol, heat to 60°C, continue to stir and react for 2 hours, then carry out suction filtration, and dry to constant weight to obtain sodium silicate / stearic acid compos...

Embodiment 2

[0047] The preparation method of the leisure shoe sole material with anti-slip performance of the present application comprises the following steps:

[0048] (1) Heat the resistance furnace to 930°C, keep it warm for 3 minutes, then add carbon black to the resistance furnace, keep it warm for 5 minutes, then add zinc ingots, keep it warm for 16 minutes, and get carbon black composite zinc oxide whiskers, the carbon black particle size is 800 mesh, the mass ratio of carbon black and zinc oxide in carbon black composite zinc oxide whiskers is 10: 1.5;

[0049] (2) Add halloysite to a 35% ethanol solution with a mass fraction 6 times its mass, stir evenly, and then add sodium silicate and stearic acid, the mass ratio of sodium silicate and stearic acid is 1: 4. Add sodium silicate in an amount of 3.2% of the ethanol mass, heat to 65°C, continue to stir and react for 2 hours, then carry out suction filtration, and dry to constant weight to obtain sodium silicate / stearic acid compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com