Patterned photochromic transparent film and preparation method thereof

A technology for photochromic and photochromic materials, applied in the field of patterned photochromic transparent films and their preparation, can solve the problems of reduced transparency, insufficient bonding, and inability to form patterns, and achieves improved service life and good mechanical properties. , the effect of improving transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The invention provides a method for preparing a patterned photochromic transparent film, comprising the following steps:

[0030] S1, using electrospinning method or melt blending spinning method to prepare nanofiber membrane;

[0031] S2. Disperse the photochromic material in a solvent to form a mixed solution; then apply the mixed solution to the surface of the nanofiber membrane obtained in step S1 according to a preset pattern by coating, spraying or stencil printing;

[0032] S3. Immerse the nanofibrous film containing the patterned photochromic material on the surface obtained in step S2 into the epoxy resin solution containing the curing agent, fully infiltrate it, take it out and cure it, and obtain the patterned photochromic transparent film.

[0033] In step S1, the material of the nanofiber membrane is a mixture of one or more of polyester, polyolefin, polyamide, and graft copolymer, and the diameter of the nanofiber is 50-500nm; the nanofiber The difference...

Embodiment 1

[0039] This embodiment provides a method for preparing a patterned photochromic transparent film, comprising the following steps:

[0040] S1. Preparation of nanofibrous membrane

[0041] Prepare vinyl alcohol-ethylene graft copolymer (PVA-co-PE) nanofiber membrane by melt blending spinning method, the specific method is as follows:

[0042] Blend PVA-co-PE and cellulose ester (CAB) according to the weight ratio of 20:80, and then use twin-screw melt blending for spinning to prepare PVA-co-PE / CAB blended fibers; then use acetone PVA-co-PE nanofibers are obtained after removing the CAB in the blended fibers; the diameter range of the obtained PVA-co-PE nanofibers is 50-500nm; the nanofibers are dispersed in isopropanol and water with a mass ratio of 1:1 High-speed shear dispersion is carried out in the mixed solvent, and a PVA-co-PE nanofiber film is obtained by a film coating method, and its mass is weighed as 0.041g.

[0043] S2. Preparation of patterned photochromic material...

Embodiment 2~5

[0055] Embodiments 2 to 5 respectively provide a method for preparing a patterned photochromic transparent film. Compared with Example 1, the difference is that the mass of the nanofiber film accounts for the mass of the nanofiber film and the epoxy resin coating layer. percentage of the total mass.

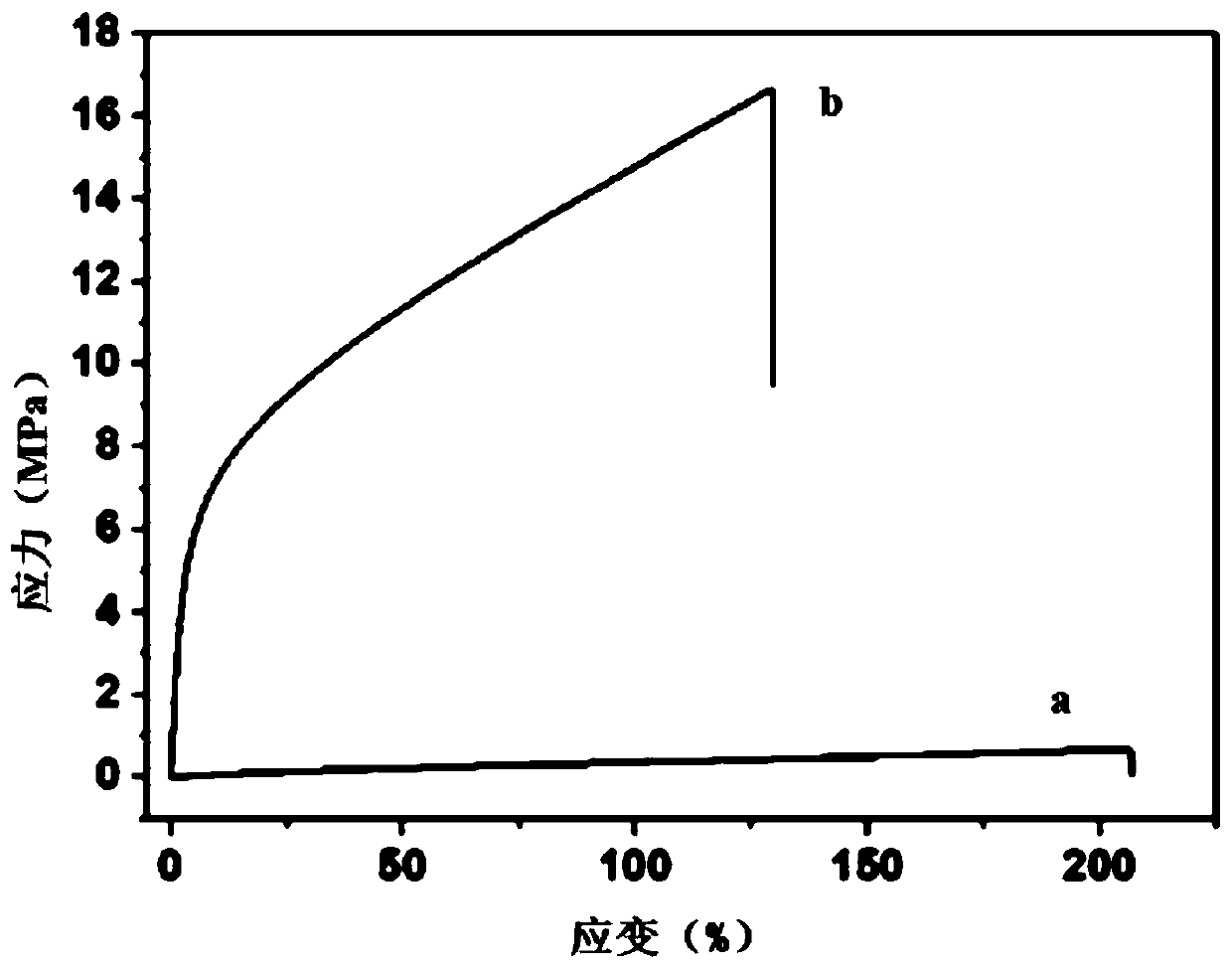

[0056] The transparency and tensile strength of the products obtained in Examples 1-5 and Comparative Examples 1-2 were tested, and the results are shown in Table 1.

[0057] Transparency and tensile strength of nanofiber content and gained product in Table 1 embodiment 1~5 and comparative example 1~2

[0058]

[0059]

[0060] It can be seen from Table 1 that the transparency and tensile strength of the prepared photochromic transparent film can be adjusted by changing the percentage of the nanofiber film to the total mass of the nanofiber film and the epoxy resin coating layer. Among them, with the decrease of the percentage of the nanofiber film, the transparency of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com