Novel rotation stepped heat storage type air preheater

An air preheater, regenerative technology, applied in the direction of heat storage equipment, indirect heat exchangers, heat exchanger types, etc. The problem of high electrical rate, to achieve the effect of improving thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

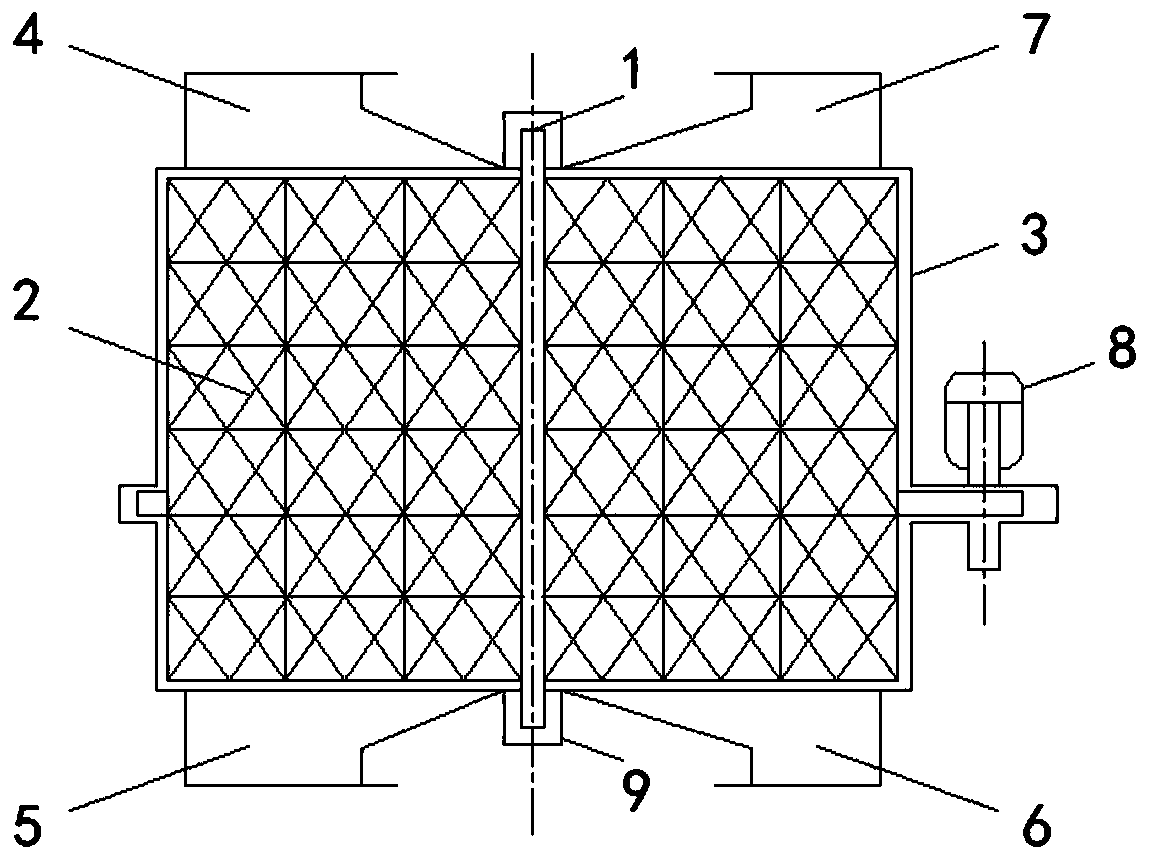

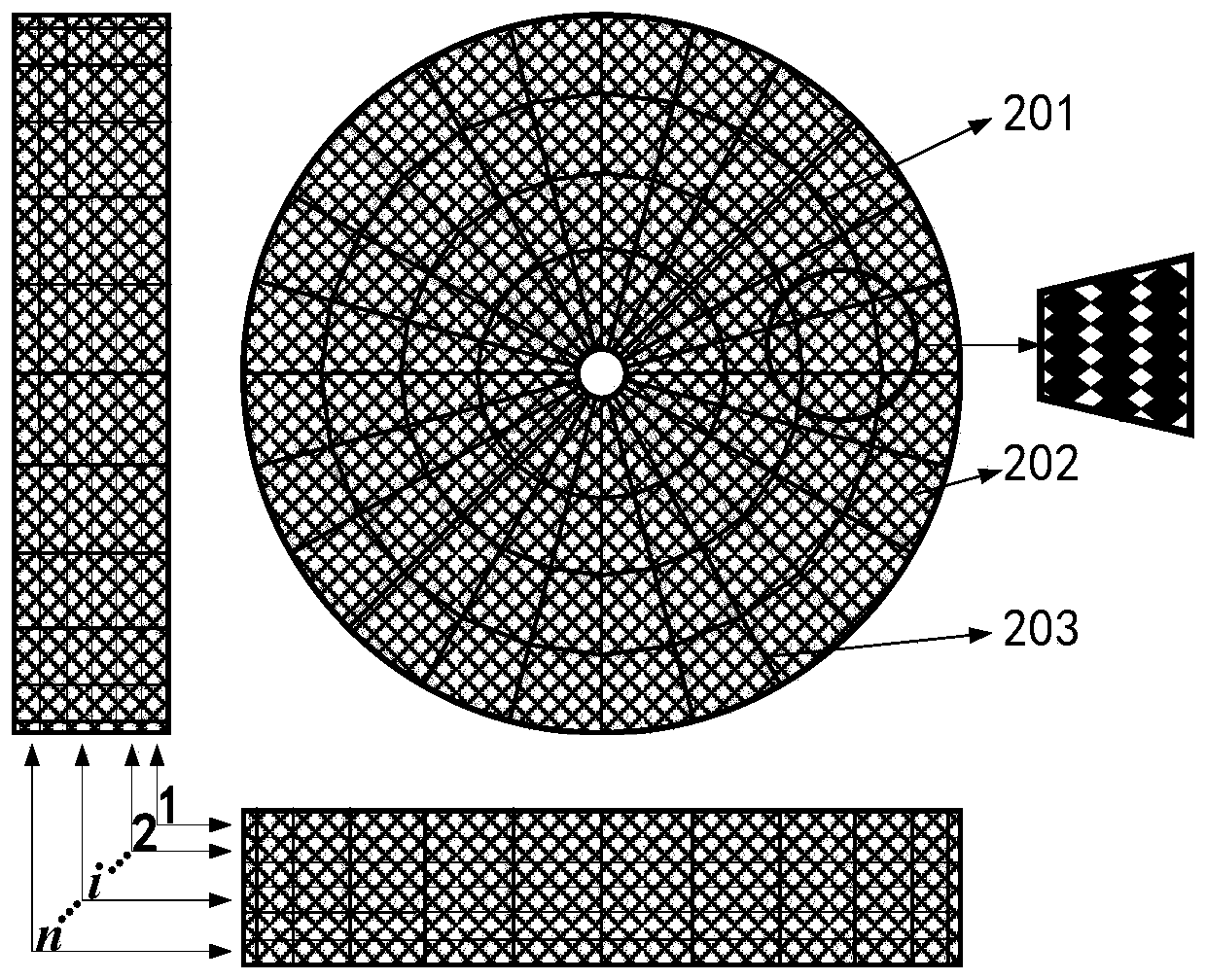

[0032] Such as figure 1 As shown, a new type of rotary cascade heat storage air preheater provided by the present invention includes a central cylinder 1 , a cascade phase change heat storage rotor 2 , a casing 3 , a driving device 8 and a sealing device 9 .

[0033] Wherein, the rotatable central cylinder 1 is driven by the driving device 8, and rotates coaxially and at the same angular speed with the stepped phase-change heat storage rotor 2 . The casing 3 is provided with a rectangular gas channel, and the flue gas denitrated by the SCR device enters the cascaded phase change heat storage rotor 2 from the flue gas inlet channel 4, and transfers heat to the phase change heat storage unit. Outlet channel 5 discharges. The air enters the cascaded phase change heat storage rotor 2 from the air inlet passage 6, is heated by the phase change heat storage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com