Preparation method of long-circulation silicon monoxide/carbon composite negative electrode material

A technology of silicon oxide and negative electrode materials, applied in the direction of negative electrodes, battery electrodes, active material electrodes, etc., can solve the problems of short cycle life of silicon-carbon composite negative electrode materials, unstable coating layer, long carbon coating time, etc. Achieve the effects of promoting rapid charge and discharge, high mechanical strength, and improving electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

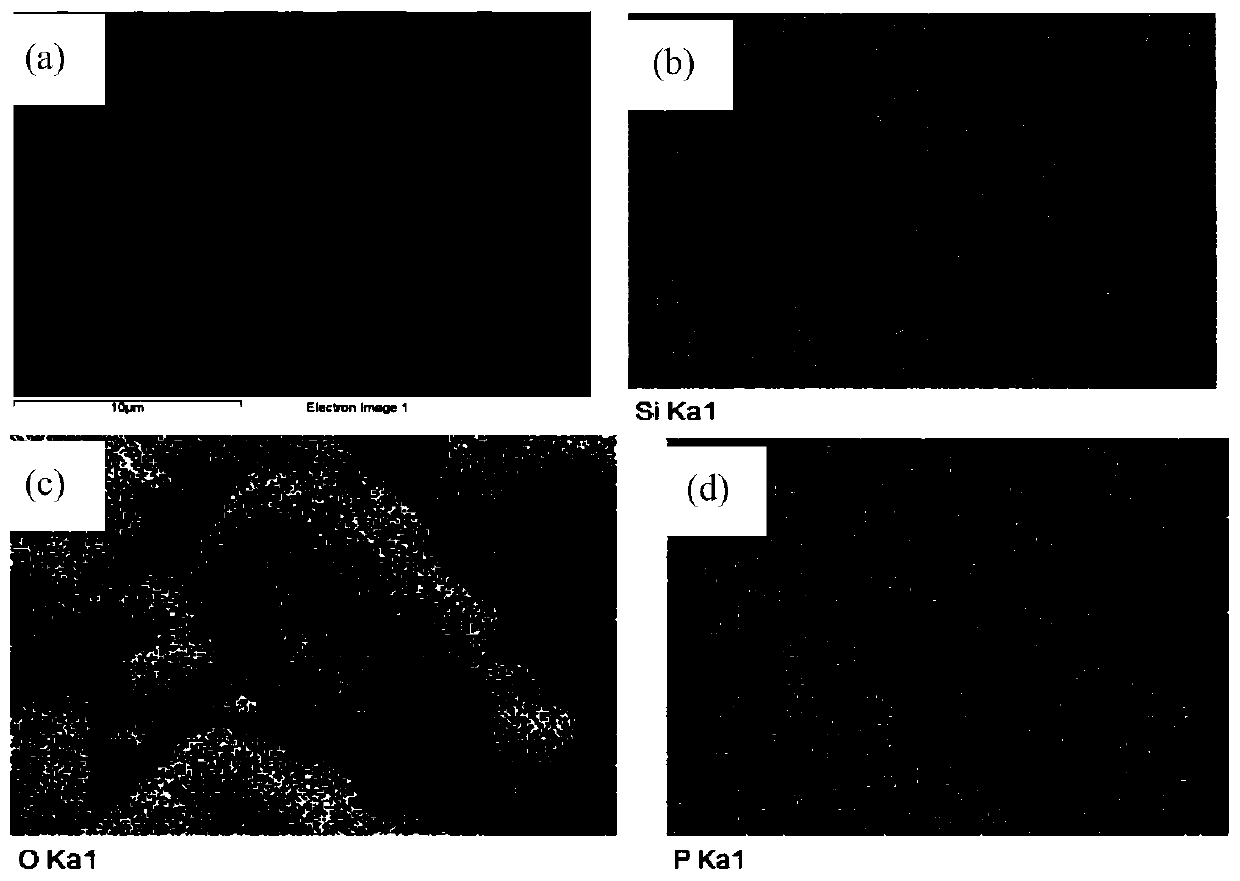

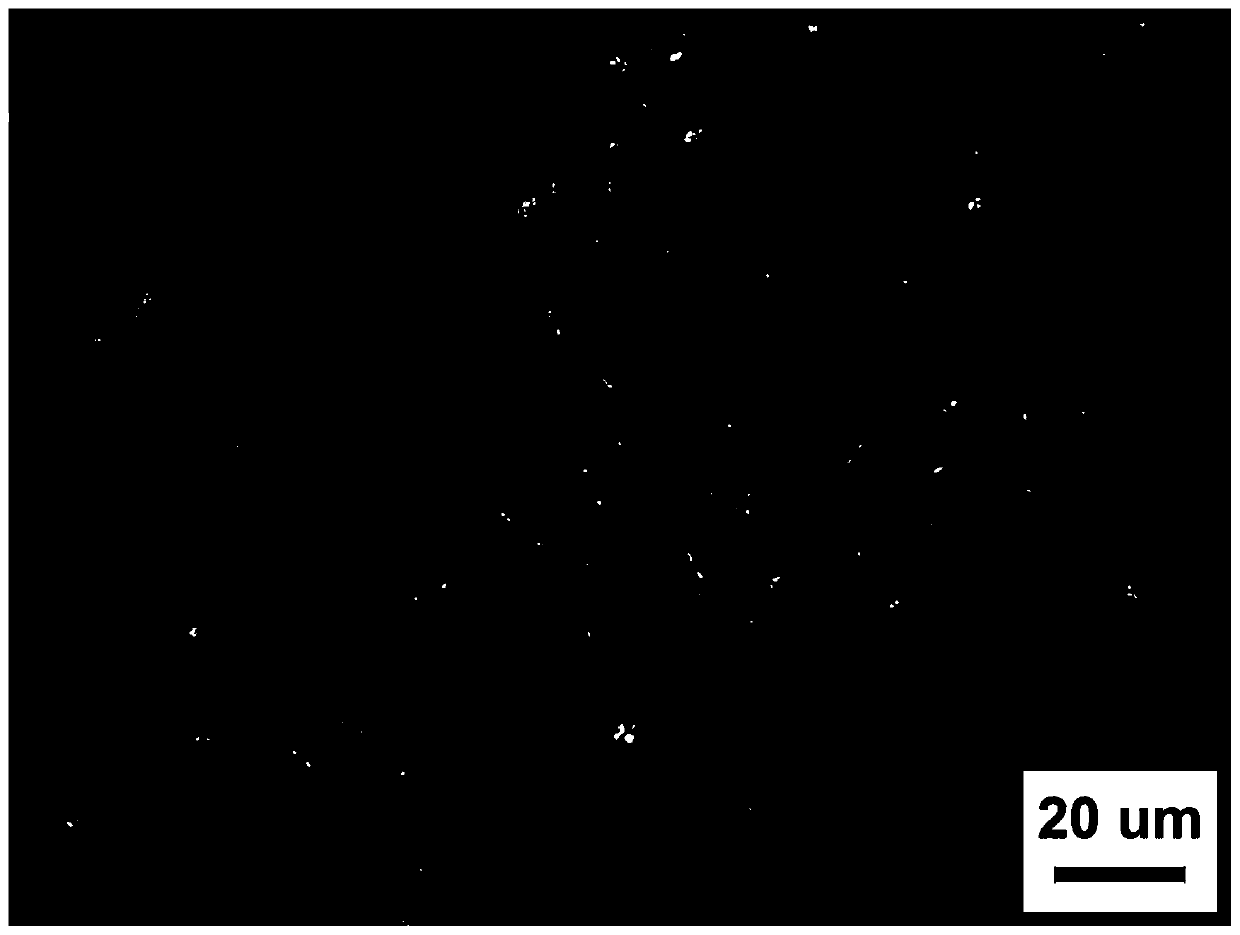

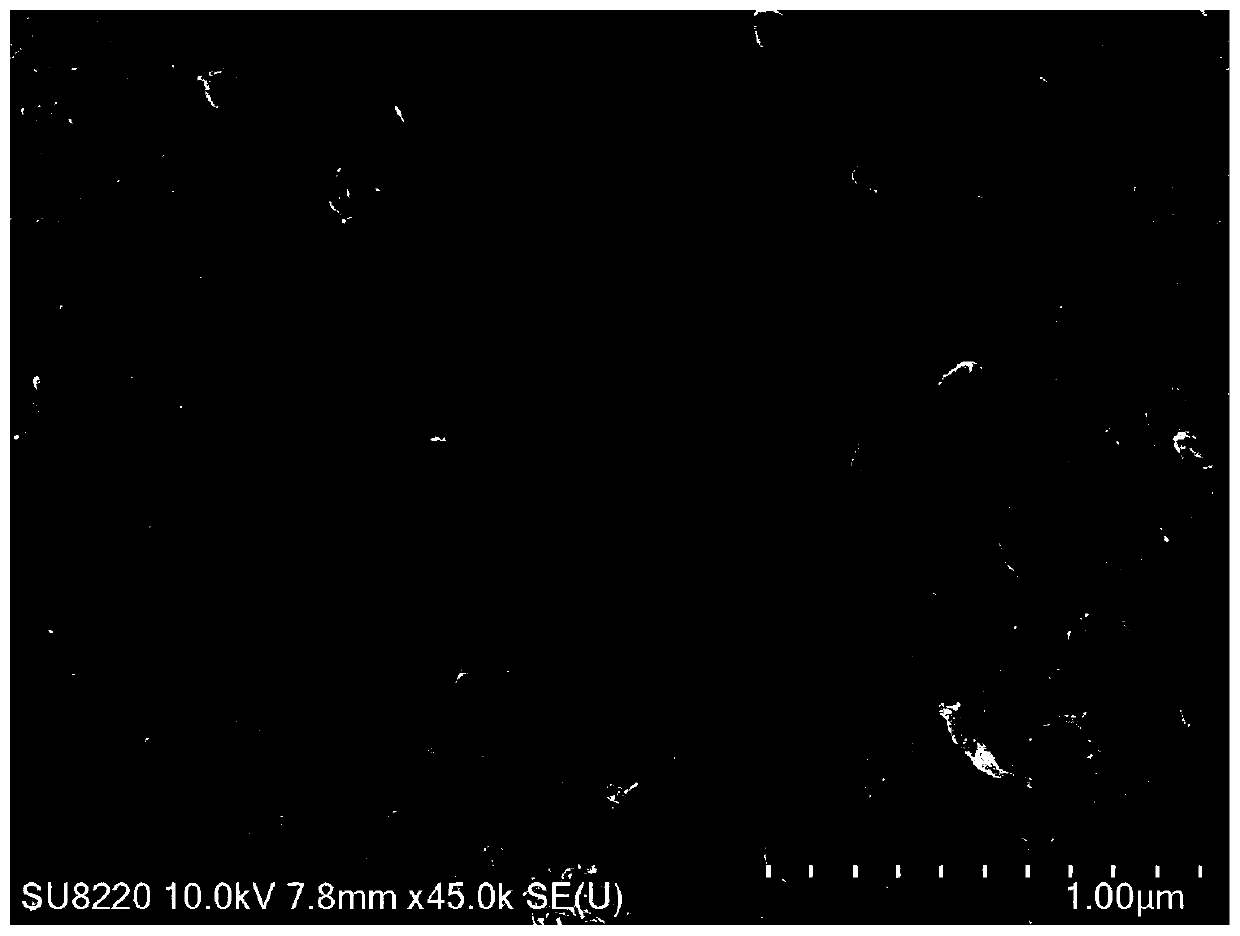

Embodiment 1

[0055] 5 kg of SiO powder with a median diameter of D50 = 3 μm was evenly dispersed in a phosphoric acid solution with a concentration of 1 mol / L. After spray drying, it was heated to 900 ° C in a tube furnace and sintered at high temperature for 2 hours to obtain phosphorus-doped SiO powder. After being crushed by a jet mill, soak in kerosene, and inductively heat to 950°C in a CLVD furnace, while feeding nitrogen protection with a flow rate of 20L / min, and the deposition time is controlled at 3min. Kerosene is cracked at high temperature, and pyrolytic carbon is coated on the surface of nitrogen-doped SiO. Then mix it evenly with 1wt% ferrocene powder, soak it in kerosene, and heat it up to 950°C by induction in a CLVD furnace. At the same time, the flow rate is 20L / min nitrogen protection, and the deposition time is controlled at 2min. Kerosene is catalytically cracked to generate CNTs in situ on the outer surface of the carbon coating.

[0056] Using a jet mill, the parti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com