Preparation of composite fluorescent nanoprobe and its detection method for hydrogen peroxide

A nano-probe and composite fluorescence technology, applied in the field of nano-probes, can solve the problems of detection environment interference, long reaction detection time, low selection specificity, etc., and achieve the later purification process easier, good detection selectivity, and high efficiency The effect of detecting the target

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1: the synthesis of CdSe@ZnS quantum dots

[0044] CdCl 2 2H 2 Dissolve O (38.4 mg) and NAC (27.5 mg) in 80 mL of ultrapure water, mix and stir evenly, adjust the pH of the solution to 9 with NaOH, add 170 μL of NaHSe solution, stir at room temperature for 2 h, and transfer the reaction solution to 100 °C Heated for 6 h, then added 3 mL of Zn(OAc) 2 2H 2 O and 3 mL of Na 2 S·9H 2 O solution to obtain CdSe@ZnS quantum dots.

[0045] Wherein, the concentration of NaOH is 1mol / L, NaHSe solution is made of Se powder (39.5mg) and NaBH 4 (40mg) was reacted in 2mL ultrapure water, Zn(OAc) 2 2H 2 O and Na 2 The concentrations of S were 11.5 mg / mL and 12 mg / mL, respectively.

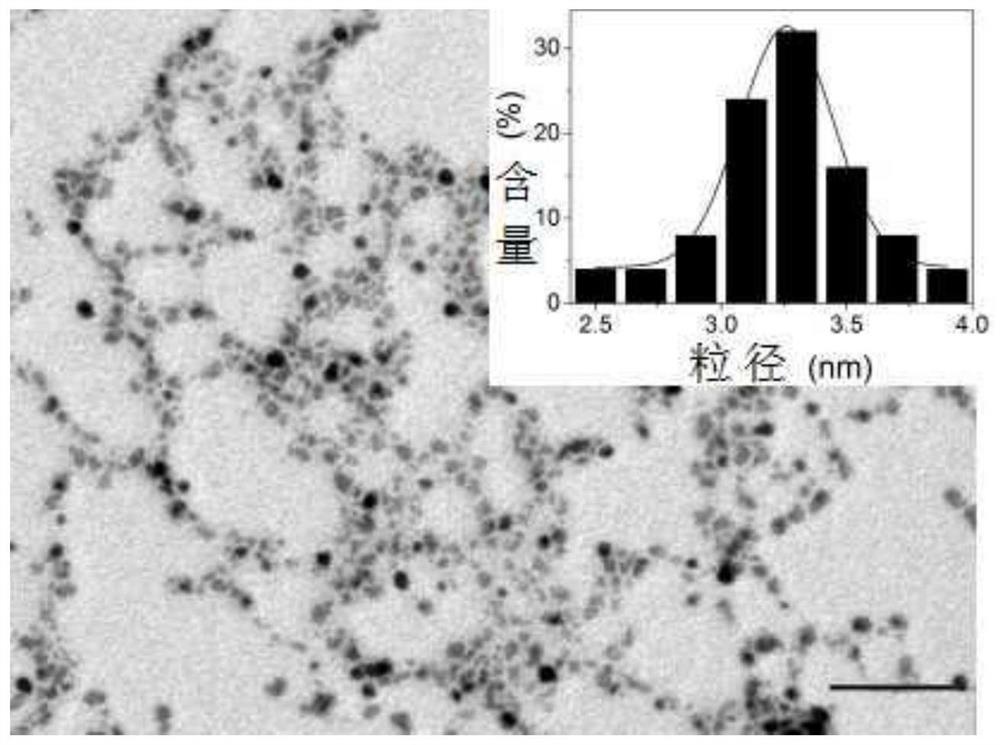

[0046] The perspective electron microscope picture is as follows figure 1 As shown, the as-prepared CdSe@ZnS quantum dots show good dispersion and are spherical in shape, and the corresponding Gaussian fitting results of the histograms obtained from the TEM images of CdSe@ZnS quantum do...

Embodiment 2

[0047] Embodiment 2: Synthetic AgNCs

[0048] Weigh 52.6 mg of DL-lipoic acid and dissolve it in 20 mL of ultrapure water, add 400 μL of NaOH solution (1mol / L), stir until completely dissolved, then add 2 mL of NaBH 4 (0.24mg / mL) solution and 0.5mL of AgNO 3 (25mM) solution to prepare nano-silver clusters.

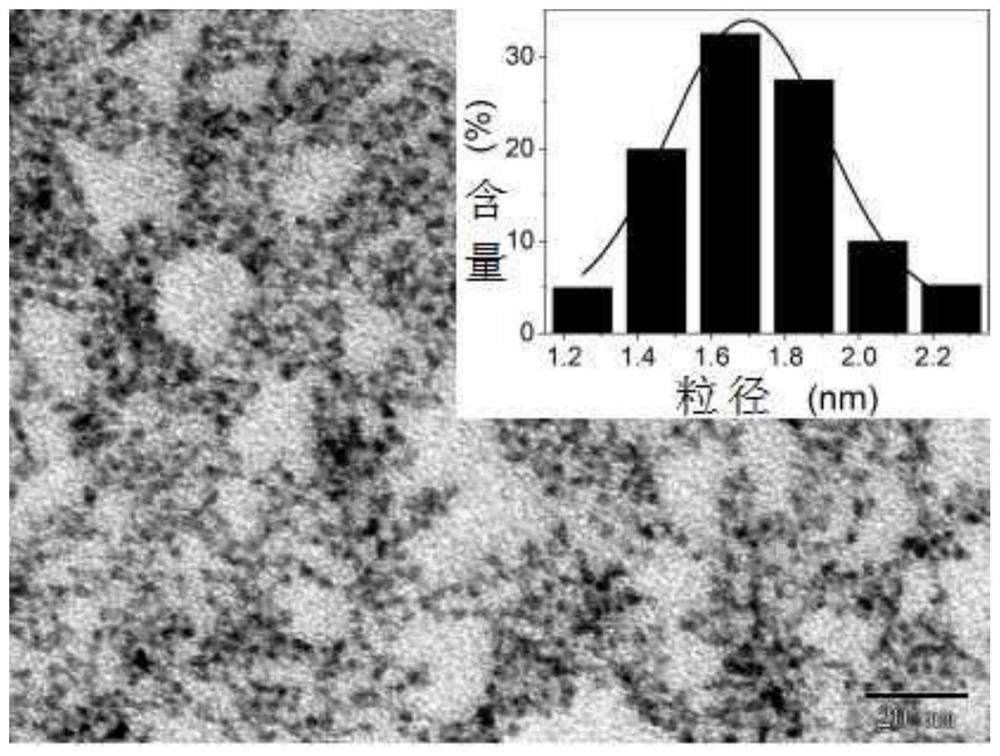

[0049] The perspective electron microscope picture is as follows figure 2 As shown, the synthesized nano-silver clusters are spherical, and the dispersion is good, and its particle size is 1.7 ± 0.5nm.

Embodiment 3

[0050] Example 3: Construction of CdSe@ZnS / AgNCs composite fluorescent nanoprobe

[0051] 20 μL of CdSe@ZnS quantum dot solution (3.2 mg / mL) and 20 μL of AgNCs solution (1.5 mg / mL) were diluted to 2 mL with Tris-HCl (pH=7.4) solution and incubated together for 10 min to prepare CdSe@ZnS ZnS / AgNCs composite fluorescent nanoprobes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com