Normal-temperature low-acid gel type dairy dessert capable of preventing browning and preparation method of normal-temperature low-acid gel type milk-containing dessert

A gel-type, acid-gel technology, applied in dairy products, other dairy products, food ingredients, etc., can solve the problems of product viscosity drop, colloid system damage, quality reduction, etc. The effect of no layering and milky appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

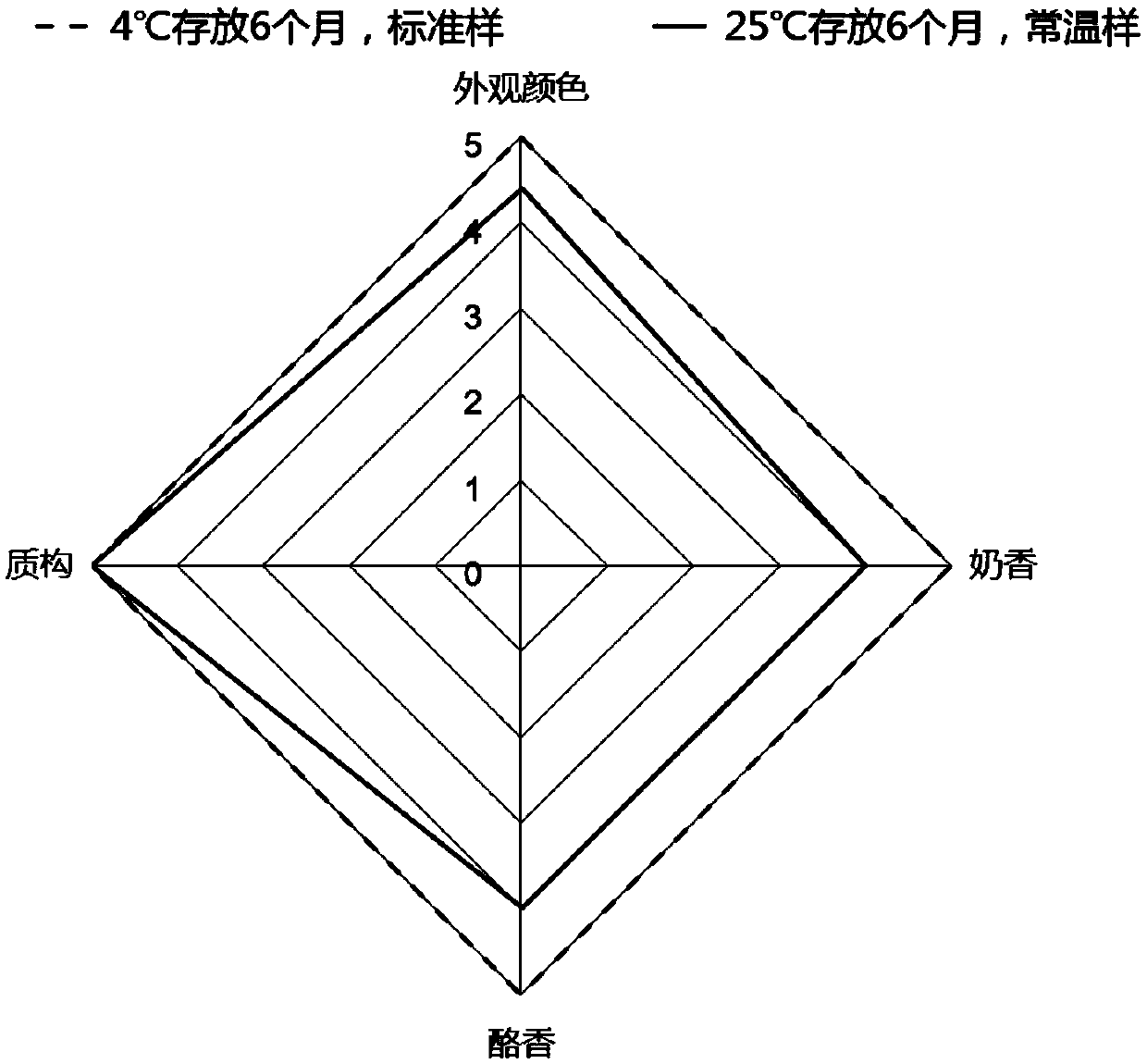

Image

Examples

Embodiment 1

[0047] This embodiment provides a processed cheese whose raw material composition is shown in Table 1 and whose raw material standards are shown in Table 2.

[0048] Table 1

[0049] raw material percentage% water 50.67 cream cheese 30 Trehalose 12 Xylitol 4 starch 2 xanthan gum 0.25 Carrageenan (lota) 0.15 Carrageenan (kappa) 0.1 Locust Bean Gum 0.25 lactic acid 0.1 Sodium citrate 0.18 Molecular Distilled Monoglyceride 0.3

[0050] Table 2

[0051]

[0052]

[0053] Other components meet the national food standards.

[0054] The preparation process of the processed cheese provided in this embodiment is as follows:

[0055] 1) Cut the cream cheese into small pieces with a size of 0.5-1cm through a dicing machine;

[0056] 2) Mix the powder with an appropriate amount of water at 70-90°C, mix evenly with a high-speed shearing machine, stir and dissolve, keep warm for 20 minutes in th...

Embodiment 2

[0067] This example provides a processed cheese whose raw material composition is shown in Table 3.

[0068] table 3

[0069]

[0070]

[0071] Raw material standard is with embodiment 1. The steps of the preparation method are the same as in Example 1.

Embodiment 3

[0073] This embodiment provides a processed cheese whose raw material composition is shown in Table 4.

[0074] Table 4

[0075] raw material percentage% water 50.67 cream cheese 30 Trehalose 12 Xylitol 4 Acetylated starch 2 xanthan gum 0.25 agar 0.25 Locust Bean Gum 0.25 lactic acid 0.1 Sodium citrate 0.25 sodium caseinate 0.3

[0076] Raw material standard is with embodiment 1. The steps of the preparation method are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com