Zinc acetate modified activated carbon fiber and titanium dioxide composite material and preparation method thereof

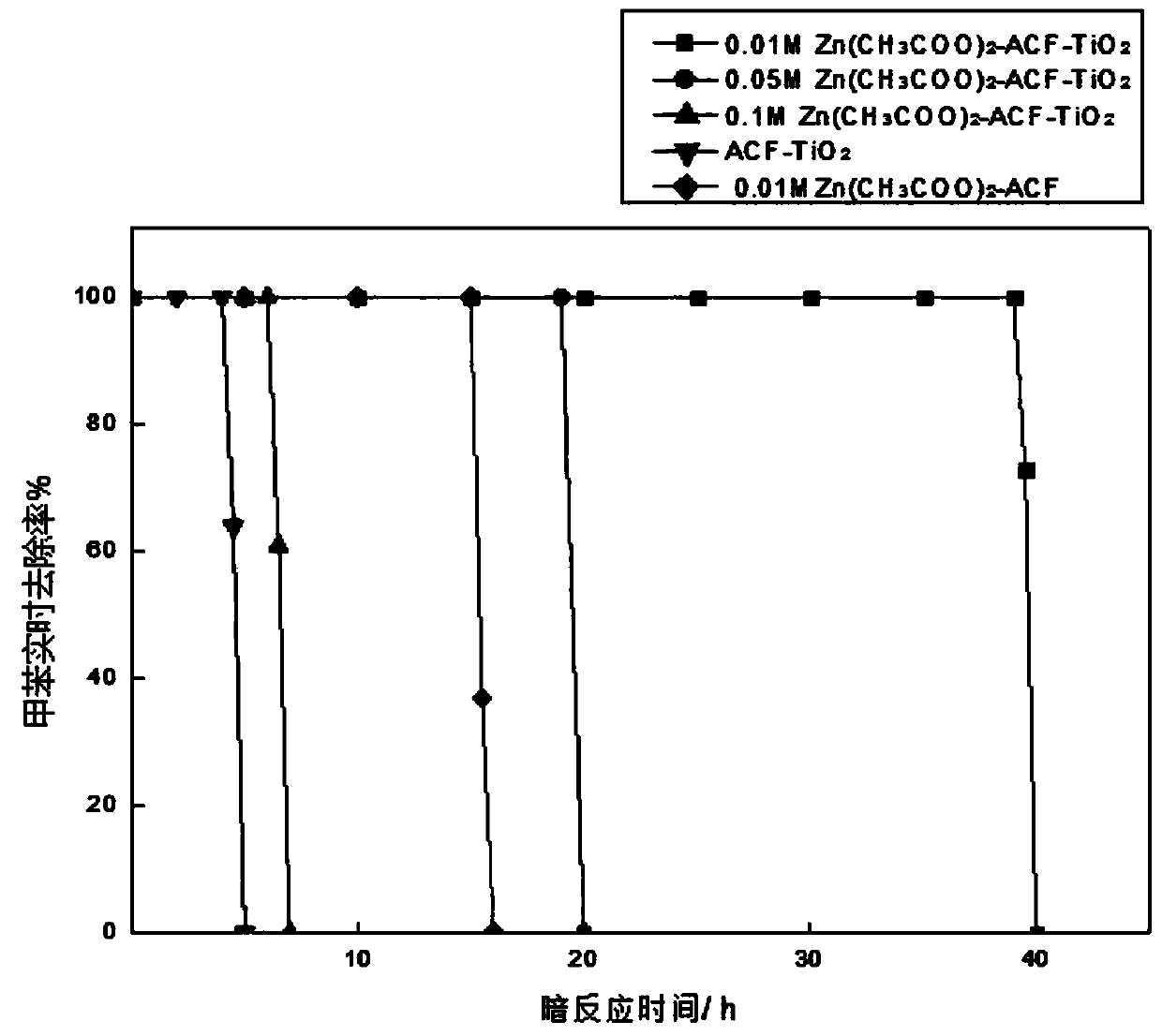

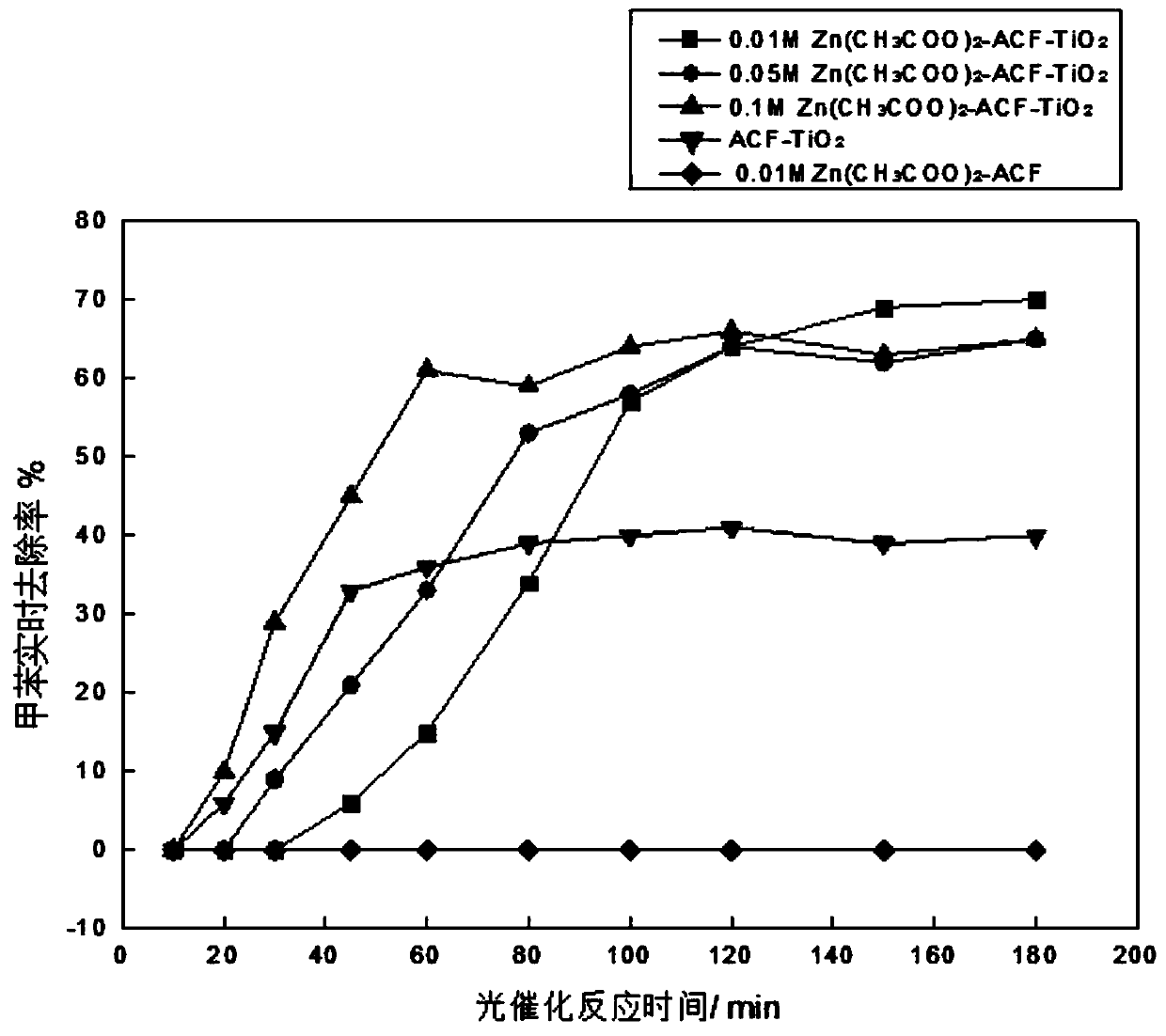

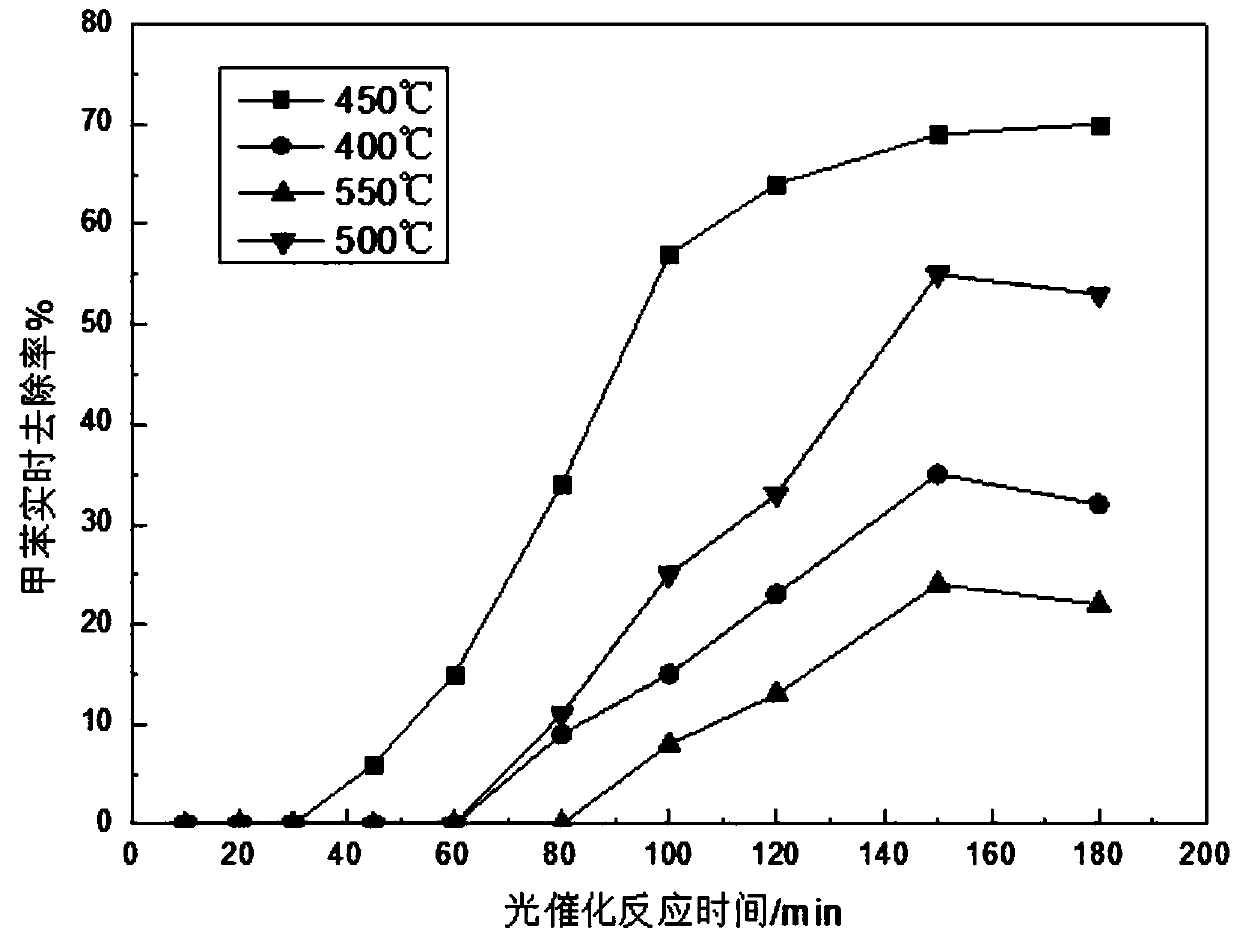

A technology of activated carbon fiber and titanium dioxide, which is applied in the field of environmental engineering, can solve the problems of inability to achieve efficient treatment, reduce specific surface area, low photocatalytic ability, etc., achieve excellent adsorption performance and photocatalytic performance, simple preparation steps, and high-efficiency removal effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The embodiment of the present invention provides a preparation method of zinc acetate modified activated carbon fiber and titanium dioxide composite material, comprising the following steps:

[0026] S1 Activated carbon fiber modification: soak the activated carbon fiber in zinc acetate solution, perform ultrasonic treatment, then put it in a vacuum drying oven for vacuum impregnation treatment, repeat the ultrasonic treatment and vacuum impregnation treatment, and take out the activated carbon fiber impregnated with zinc acetate and drying to obtain zinc acetate modified activated carbon fiber;

[0027] S2 supported titanium dioxide: add tetrabutyl titanate to the mixture of absolute ethanol and acetic acid, and stir to make solution A; mix absolute ethanol, acetic acid and deionized water, and stir to make solution B; stir vigorously , drop solution B into solution A drop by drop, stir after the dropwise addition, and leave it to age at room temperature to obtain a so...

Embodiment 1

[0039] (1) Activated carbon fiber pretreatment: Cut the activated carbon fiber into several small pieces of 2cm×2cm, soak them in deionized water, and carry out boiling treatment to remove impurities. During the boiling treatment, replace the deionized water every 0.5h. After changing the water Boil again, the total time of boiling treatment is 3h, take out the activated carbon fiber sheet, and place it in a 105°C oven to dry for 24h.

[0040] (2) Activated carbon fiber modification: Take 10 pretreated activated carbon fiber sheets and soak them in 100mL zinc acetate solution with a concentration of 0.01mol / L, and perform ultrasonic treatment on the zinc acetate solution and activated carbon fiber sheets together. 10min, the ultrasonic power is 5000Hz, then put the zinc acetate solution and the activated carbon fiber sheet into the vacuum drying oven for vacuum impregnation treatment, the vacuum impregnation treatment time is 10min, the vacuum degree is controlled within 0.06 ~...

Embodiment 2

[0043] The only difference from Example 1 is that the concentration of the zinc acetate solution is 0.05mol / L. Other steps are all the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com