Device and method for preparing cell grade methyl ethyl carbonate from dimethyl carbonate and ethanol

A technology of ethyl methyl carbonate and dimethyl carbonate, which is applied in the field of equipment for producing battery-grade ethyl methyl carbonate, can solve the problems of heat consumption in the tower kettle, influence on product content, and consumption of cooling capacity, and achieve low raw material cost and side effects The effect of less product and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

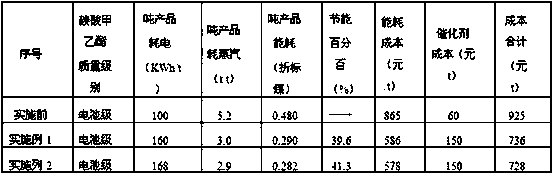

Embodiment 1

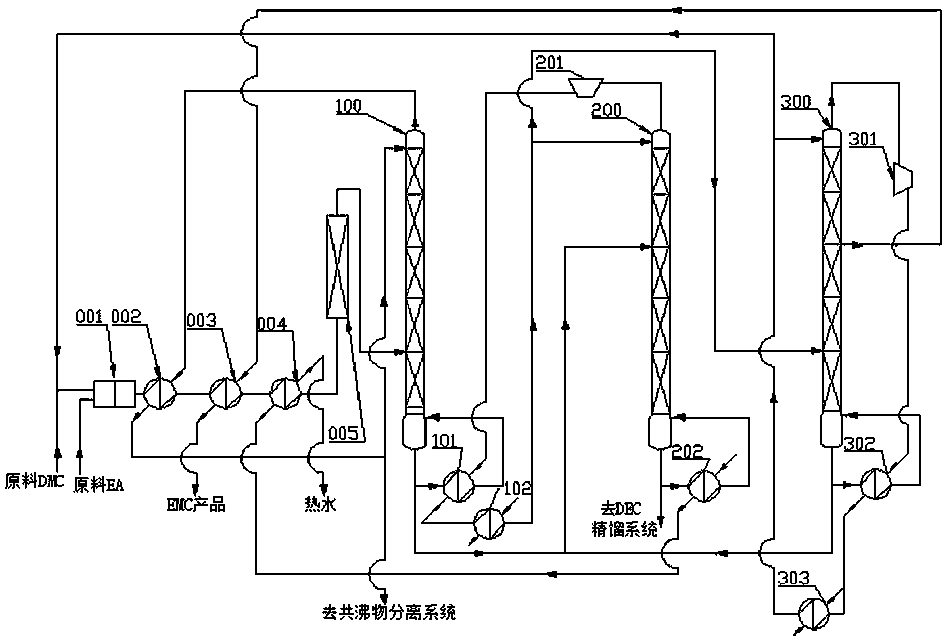

[0035] Embodiment 1, a kind of device that the present invention mentions produces battery grade ethyl methyl carbonate with dimethyl carbonate and dehydrated alcohol, its technical scheme is: comprise static mixer (001), the first preheater (002 ), second preheater (003), third preheater (004), prereactor (005), reactive distillation column (100), reactive distillation column reboiler (101), diethyl carbonate Removal tower (200), first compressor (201), diethyl carbonate removal tower reboiler (202), ethyl methyl carbonate rectification tower (300), second compressor (301), methyl carbonate Ethyl distillation column reboiler (302), first water cooler (102) and second water cooler (303),

[0036] The inlet of the static mixer (001) is connected to the raw material DMC and raw material EA feeding pipelines respectively, the outlet is connected to the inlet of the first preheater (002) tube side, and the outlet of the first preheater (002) tube side is connected to the second T...

Embodiment 2

[0056] Embodiment 2, production device is identical with embodiment 1, and production process is identical with embodiment 1, and concrete operation condition is:

[0057] Dimethyl carbonate and absolute ethanol enter the static mixer (001), the first preheater (002), the second preheater (003), and the third preheater (004) at a molar ratio of 1.2:1 Preheat to the reaction temperature of 102°C, and enter the pre-reactor (005) together for pre-reaction;

[0058] The top temperature of the reactive distillation column (100) is 64.6°C, the top pressure is 103kpa, the bottom temperature is 103°C, the bottom pressure is 108kpa, and the top reflux ratio is 4.3:1;

[0059] The temperature at the top of the diethyl carbonate removal tower (200) is 98°C, the pressure at the top of the tower is 102kpa; the temperature of the tower bottom is 131°C, the pressure of the bottom is 106kpa, and the feed inlet is 0.42 times the height of the whole tower from the reflux port; the distillation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com