A kind of magnetic fluorescent complex and its preparation method and application

A complex and fluorescence technology, which is applied in copper organic compounds, organic chemical methods, chemical instruments and methods, etc., can solve the problems of fluorescence quenching, and achieve the effect of simple preparation method, high yield and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1, preparation:

[0023] Method for preparing a magnetic fluorescent complex: First at room temperature, 121 mg of three hydrazine nitrate (0.5 mmol), 180 mg adjacent vermicellide (1 mmol), 558 mg of sodium iodide (3 mmol) and 10 ml deionized water By a 20 ml autoclave, mixing is mixed into a mixed solution. The mixed solution was then sealed to 180 ° C for reaction, and then cooled to room temperature, and finally, the reaction formed was washed repeated, and the magnetic fluorescence complex was obtained. The yield of the product was 57.3% based on the amount of three hydrogen nitrate copper used.

[0024] 2, structure characterization:

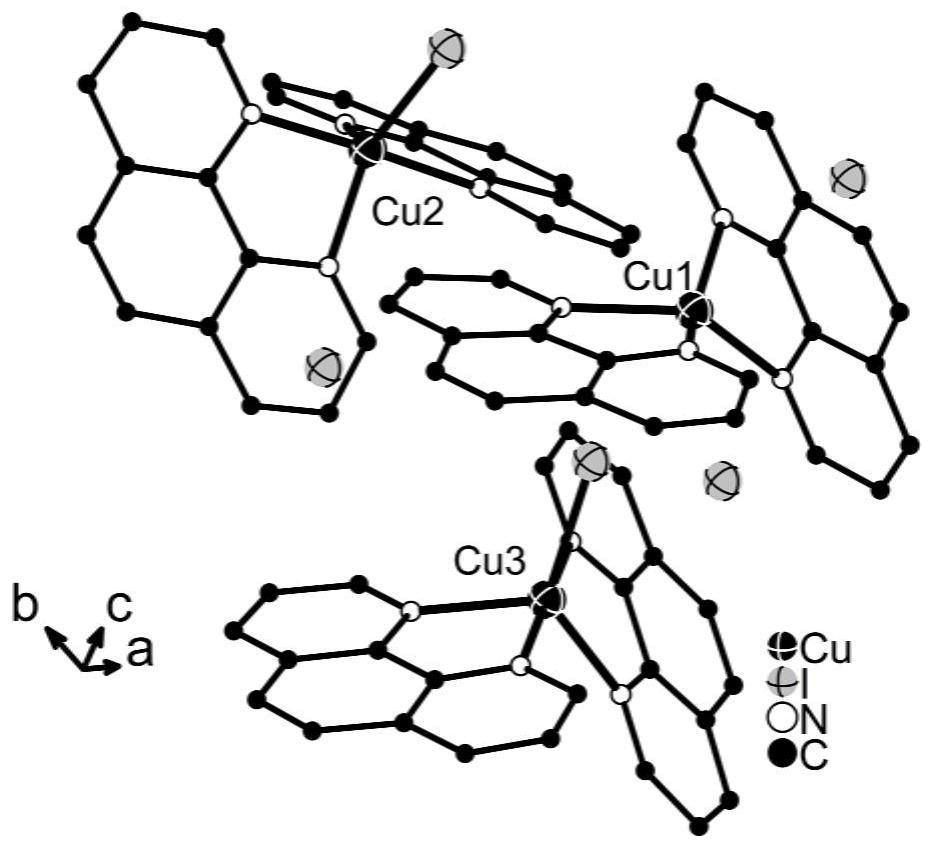

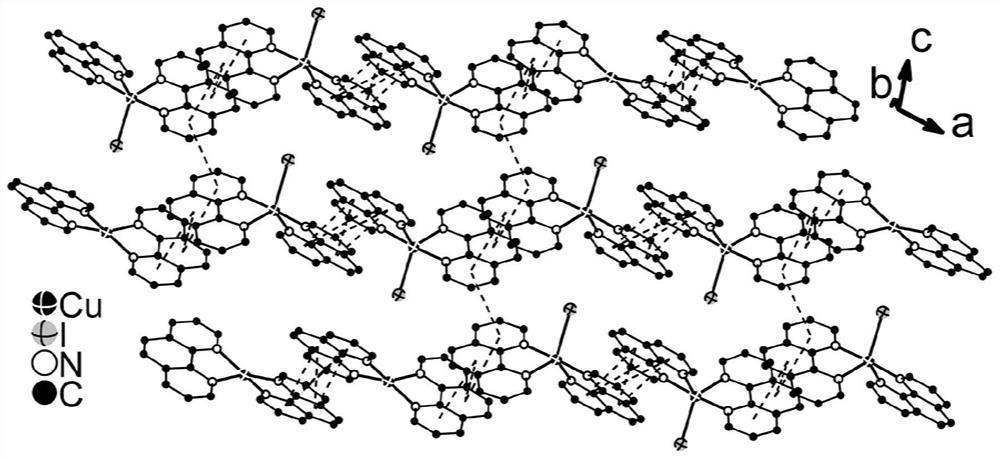

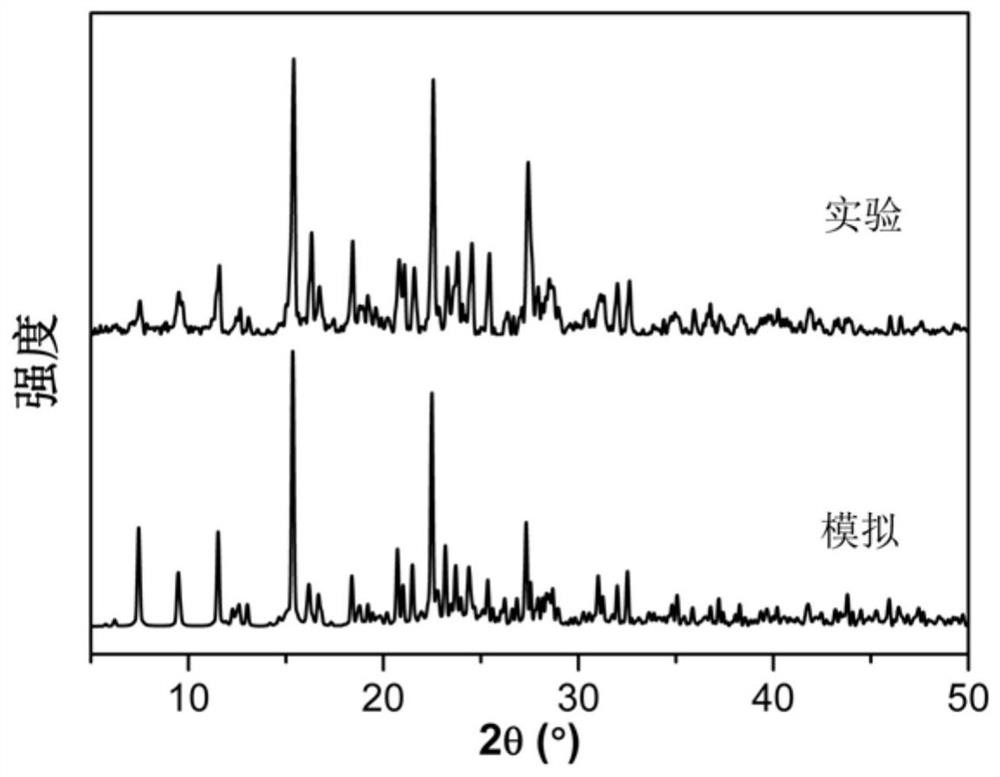

[0025] A single crystal structure of the magnetic fluorescent complex of the present invention is obtained by single crystal X-ray diffraction experiment. Such as figure 1 As shown, the chemical formula for preparing the obtained magnetic fluorescent complex is [Cui (PHEN) 2 ] 2 Cu (Phen) 2 I 3 Where Phen is adjacent to Philoline. This c...

Embodiment 2

[0034] Method for preparing a magnetic fluorescent complex: First at room temperature, 121 mg of three hydrolyzate (0.5 mmol), 360 mg o-affinity (2 mmol), 372 mg of dihydrate (2 mmol) and 12ml deionized water By a 20 ml autoclave, mixing is mixed into a mixed solution. The mixed solution was then sealed to 140 ° C for reaction, and the heat premium was 72 h, and then cooled to room temperature, and finally the reaction formed of the reaction was washed multiple times, and the magnetic fluorescence complex was obtained. The yield of the product was 59.2% based on the amount of three hydrogen nitrate copper used.

Embodiment 3

[0036]Method for preparing a magnetic fluorescent complex: First at room temperature, 121 mg of three hydroximinitrate copper (0.5 mmol), 270 mg adjacent vermiline (1.5 mmol), 744 mg of sodium iodide (4 mmol) and 14ml deionized water The mixture was mixed into a 20 ml autoclave and mixed with mixed solution was stirred. The mixed solution was then sealed to 120 ° C for reaction, and the heat preservation was 96 h, and then cooled to room temperature, and finally the reaction formed of the reaction was washed multiple times, and the magnetic fluorescent complex was obtained. The yield of the product was 53.5% by calculation of the amount of three hydrogen nitrate used.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com