Two-component organic silicon pouring sealant and application method thereof

A silicone potting compound, two-component technology, used in chemical instruments and methods, adhesives, adhesive additives, etc., can solve the problems of unfavorable overall insulation structure, poor thermal conductivity, poor heat resistance, etc. Excellent insulating properties, excellent electrical insulating properties, and the effect of reducing sedimentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

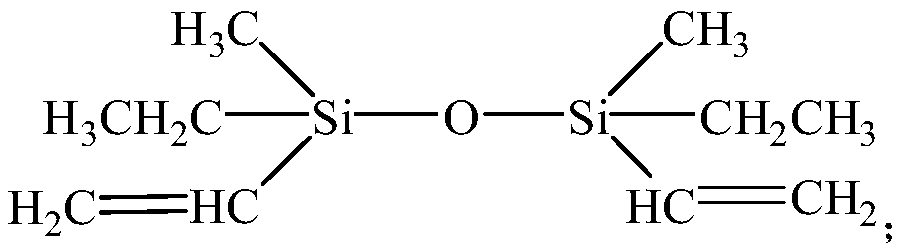

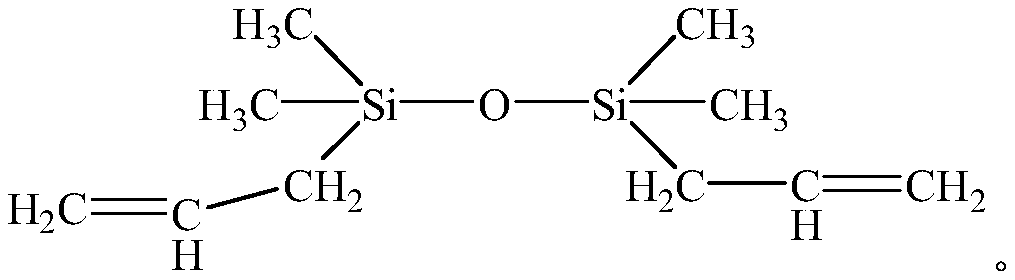

[0039] Example 1 Preparation of hyperbranched silicone resin with terminal siloxane groups

[0040] Weigh 1500 g methyl ethyl vinyl siloxane and 1500 g dimethyl allyl siloxane, mix and add 7 g of chloroplatinic acid, and then react for 5.5 hours at 75±3°C under the protection of nitrogen to produce The hyperbranched silicone resin with terminal siloxane groups has 6 terminal siloxane groups per molecule.

Embodiment 2

[0041] Example 2 Preparation of hyperbranched silicone resin with terminal siloxane groups

[0042] Weigh 2000 g methyl ethyl vinyl siloxane and 1000 g dimethyl allyl siloxane, mix and add 7 g chloroplatinic acid, and then react for 5.5 hours at 75±3°C under nitrogen protection to make The hyperbranched silicone resin with terminal siloxane groups has 12 terminal siloxane groups per molecule.

Embodiment 3

[0043] Example 3 Preparation of hyperbranched silicone resin with terminal siloxane groups

[0044] Weigh 1750g methylethylvinylsiloxane and 1250g dimethylallylsiloxane, mix and add 7g chloroplatinic acid, and then react for 5.5 hours at 75±3℃ under nitrogen protection to make The hyperbranched silicone resin with terminal siloxane groups has 8 terminal siloxane groups per molecule.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com