Making method of reaction film and ammonia nitrogen detection device and method based on reaction film

A manufacturing method and detection device technology, applied in the direction of color/spectral characteristic measurement, etc., can solve problems such as signal drift, difficulty in giving accurate judgment, complicated operation, etc., and achieve the effects of high detection accuracy, simple structure, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

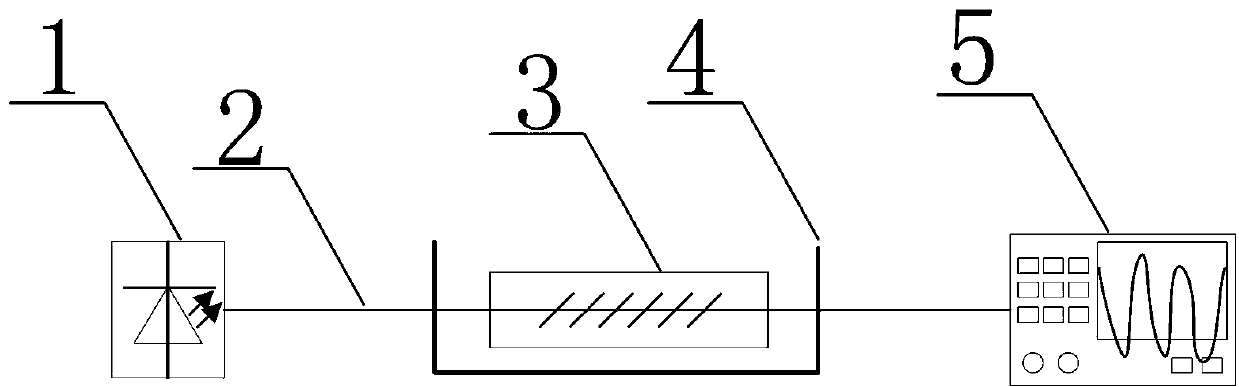

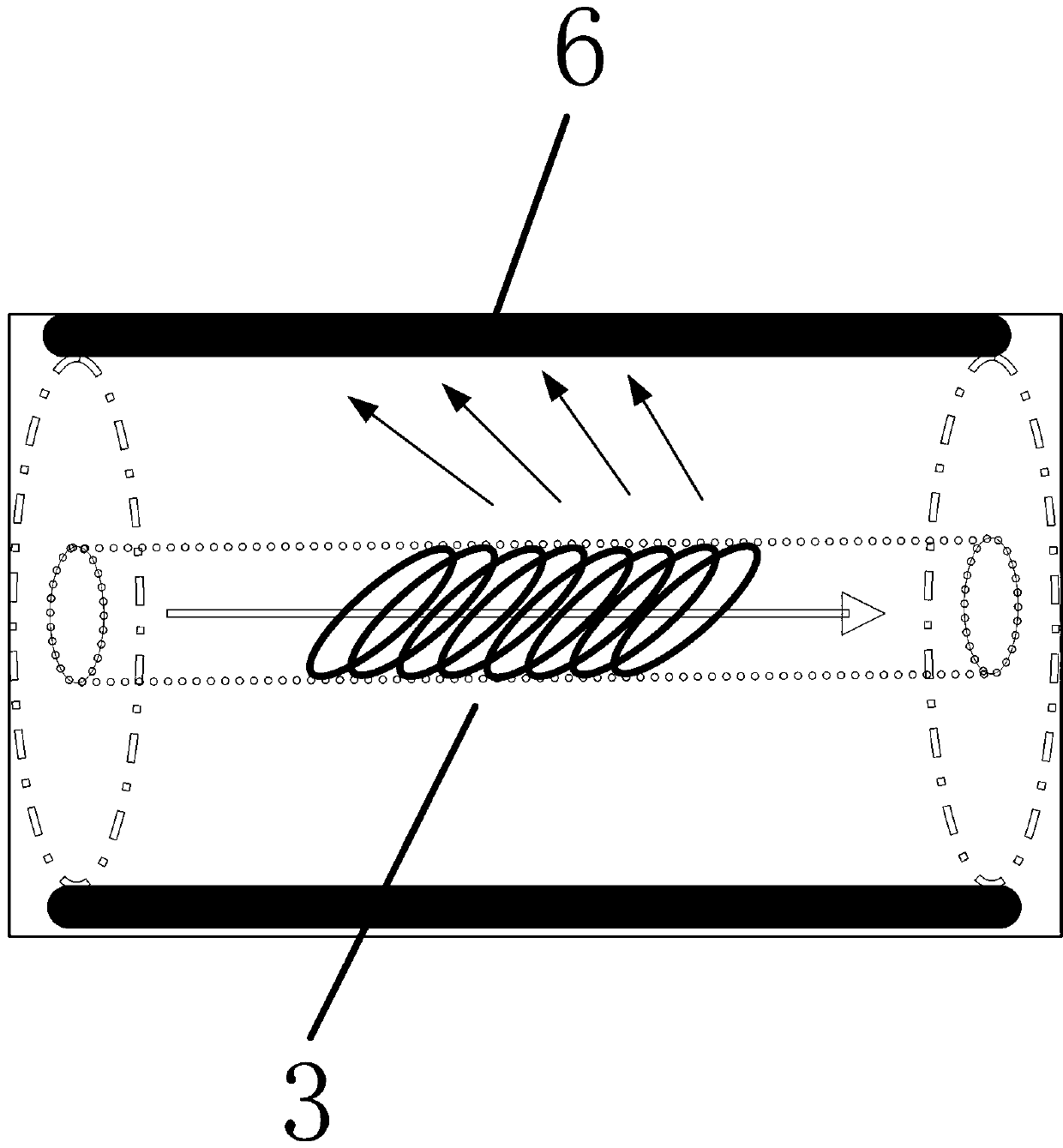

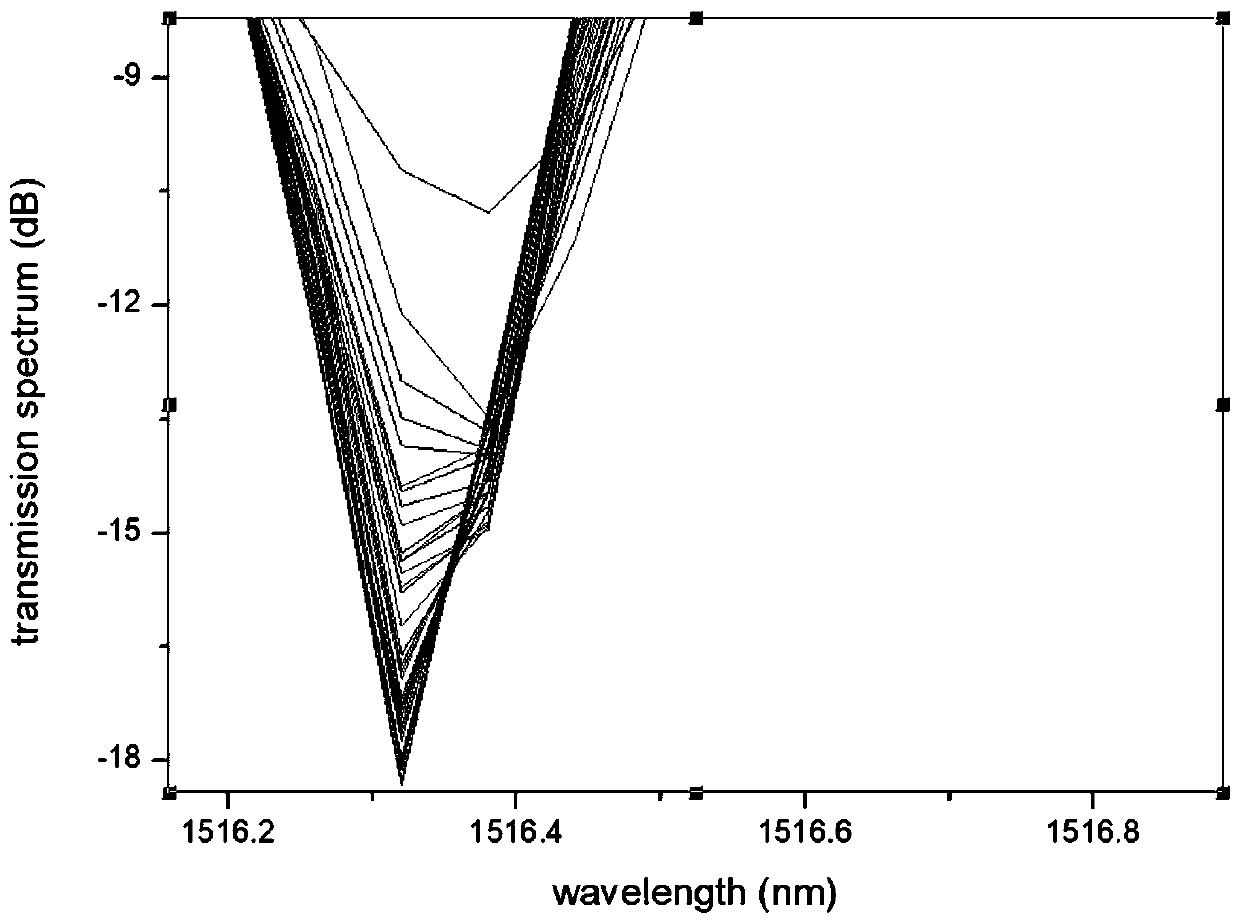

[0024] The concept, specific structure and technical effects of the present disclosure will be clearly and completely described below in conjunction with the embodiments and drawings, so as to fully understand the purpose, scheme and effect of the present disclosure. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

[0025] The preparation method of reaction membrane provided by the invention is:

[0026] (1) Configure the polyvinylidene chloride-bromothymol blue solution used for coating: the solute is polyvinylidene chloride and bromothymol blue, the organic solvent is N-methylpyrrolidone, take 0.1g polyvinylidene chloride and 0.1 1g bromothymol blue is put into the N-methylpyrrolidone solvent of 5ml, then is placed on the magnetic control stirrer and works for 6 hours, after fully stirring, obtains uniform solution;

[0027] (2) Coating on the optical fiber: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com