Polytrifluoropropyl methyl siloxane/silver composite surface enhanced Raman substrate and preparation method thereof

A technology of polytrifluoropropylmethylsiloxane and trifluoropropylmethylsiloxane is applied in the field of polytrifluoropropylmethylsiloxane/silver composite surface-enhanced Raman substrate and its preparation. It can solve the problems of size, spacing and the effect of arranging the substrate, and achieve the effects of low cost, simple preparation process and good repeatability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Clean the glass piece, soak it in concentrated sulfuric acid for 3 hours, wash it with distilled water, then soak it in 1M NaOH for 2 hours, wash it with distilled water, and finally soak it in 0.1M HCl for 30 minutes, wash it with distilled water and put it at 120°C Oven dry overnight;

[0025] (2) Take 3g of methyltrimethoxysilane, add 2mL of trifluoroacetic acid (containing 5% water), shake and mix for 1 hour, then add 2.5g of polytrifluoropropylmethylsiloxane, shake and mix, and pipette Take 100 μL of the mixed solution with a gun and drop it on a glass slide, and let it dry naturally to form a film;

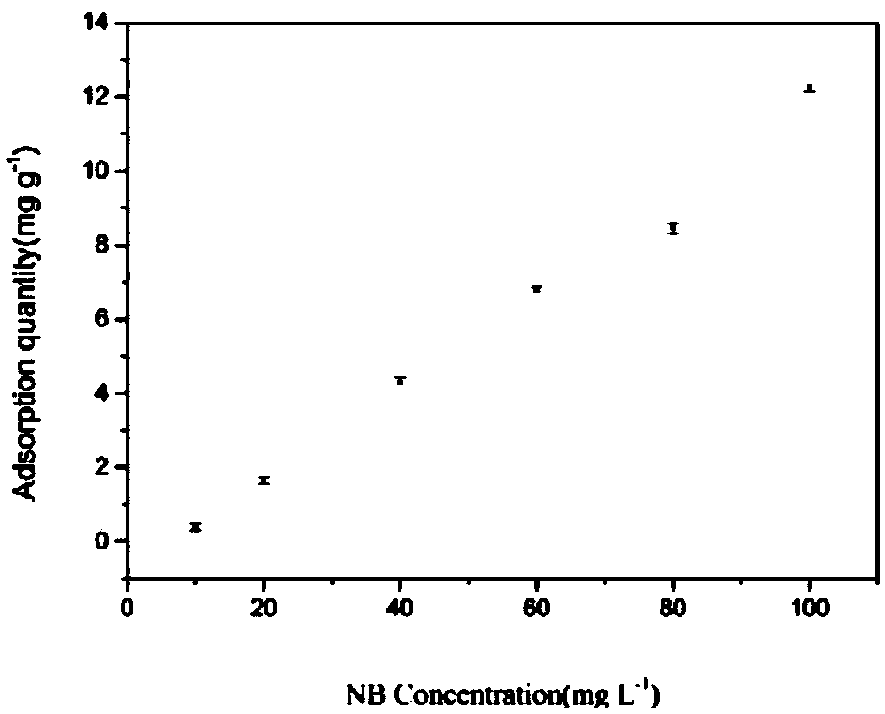

[0026] (3) Place the membrane described in step (2) in nitrobenzene solutions of different concentrations and vibrate at a constant temperature. After the adsorption reaches equilibrium, the absorbance is measured by ultraviolet spectrophotometry, and the polytrifluoropropylmethylsiloxane is calculated by the formula Adsorption capacity of p-nitrobenzene by alkan...

Embodiment 2

[0031] (1) The polytrifluoropropylmethylsiloxane obtained in Example 1 is placed in silver nanoparticle solutions of different concentrations and soaked for 24h to obtain polytrifluoropropylmethylsiloxane / silver containing different silver contents. Composite surface-enhanced Raman substrates.

[0032] (2) Immerse the obtained polytrifluoropropylmethylsiloxane / silver composite surface-enhanced Raman substrate in 10 -7 In the solution of the probe molecule (4-mercaptoaniline) of M concentration, the corresponding surface-enhanced Raman spectrum is obtained.

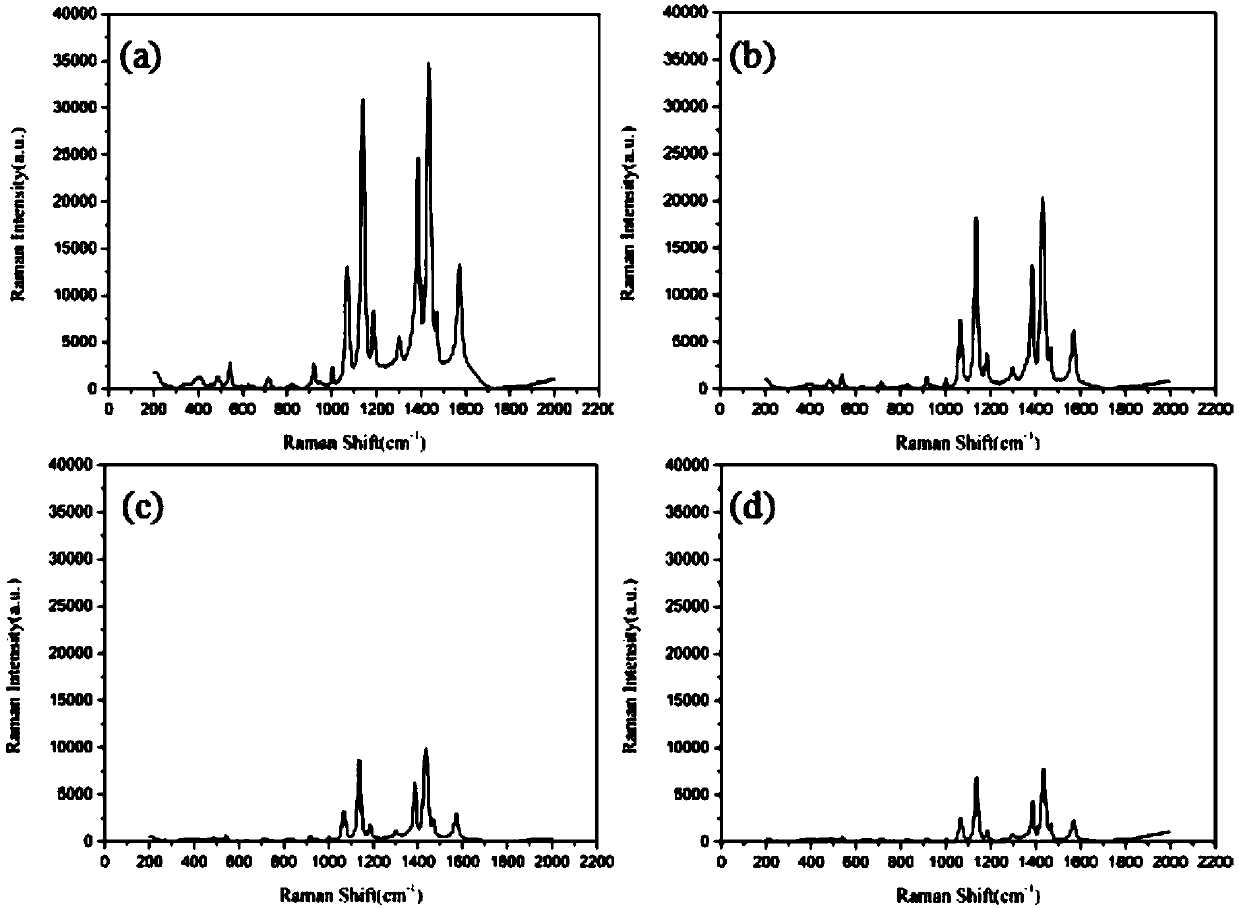

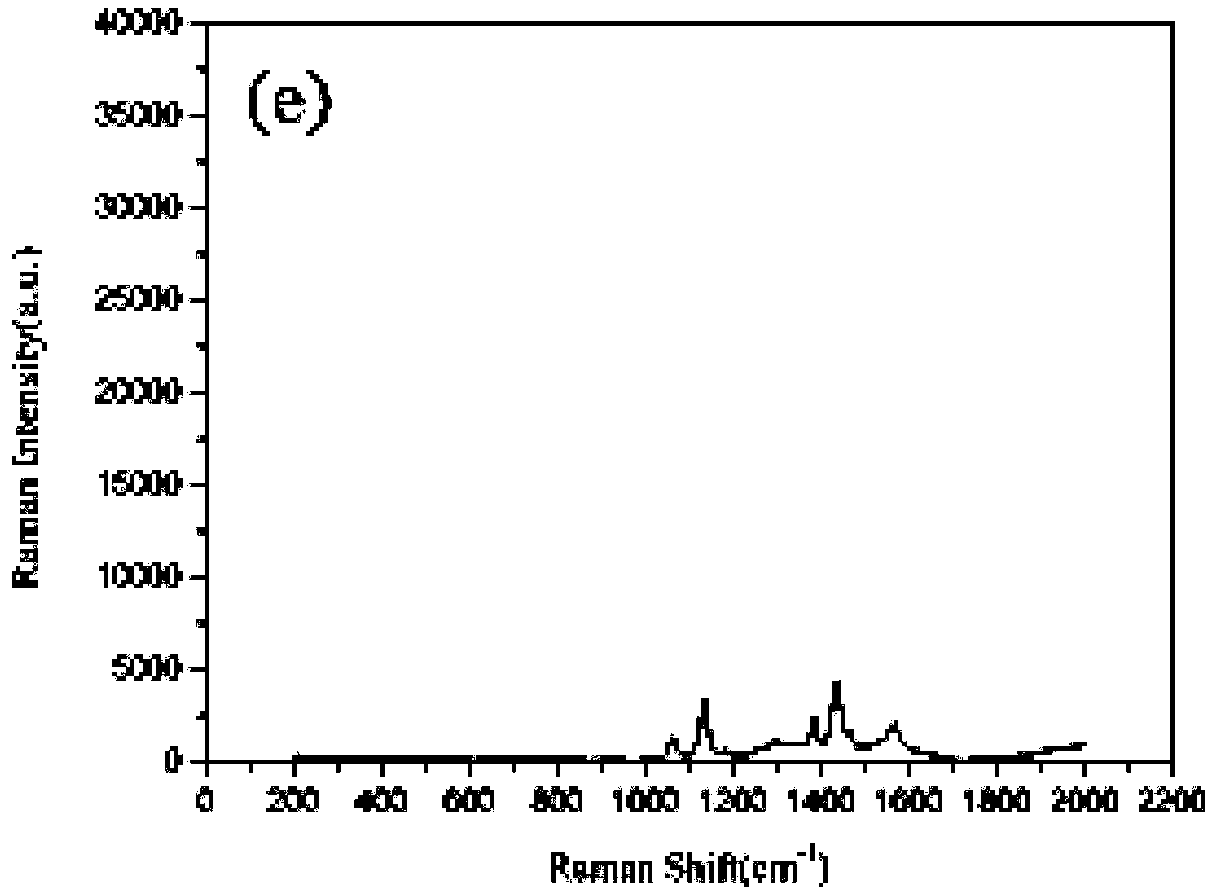

[0033] Polytrifluoropropylmethylsiloxane / silver composite surface-enhanced Raman substrate pairs prepared by the above-mentioned silver nanoparticles with different concentrations 10 -7 The Raman spectrum of the M concentration probe molecule (4-mercaptoaniline) is as follows figure 2 As shown (a.0.2mM; b.0.4mM; c.0.6mM; d.0.8mM; e.1.0mM), it can be seen that with the increase of the concentration of Ag nanoparticles, t...

Embodiment 3

[0036] (1) Soak the polytrifluoropropylmethylsiloxane obtained in Example 1 in a silver nanoparticle solution with a concentration of 0.2 mM for 24 hours to obtain a polytrifluoropropylmethylsiloxane / silver composite surface-reinforced coating. Mandi.

[0037] (2) The obtained polytrifluoropropylmethylsiloxane / silver composite surface-enhanced Raman substrate was immersed in different concentrations of nitrobenzene solutions, and the corresponding surface-enhanced Raman spectra were obtained.

[0038]The above prepared polytrifluoropropylmethylsiloxane / silver composite surface-enhanced Raman substrate is compared to the Raman confirmation spectrum of pure nitrobenzene Figure 5 Shown, respectively for polytrifluoropropylmethylsiloxane film, polytrifluoropropylmethylsiloxane film + pure nitrobenzene, silver nanoparticles + pure nitrobenzene, polytrifluoropropylmethylsiloxane Silicone / silver composite surface-enhanced Raman substrate + pure nitrobenzene for Raman detection, it ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com