Preparation method of efficient titanium-based photocatalyst

A photocatalyst, titanium-based technology, applied in the field of photocatalysis, can solve the problem of low electron yield of nano-titanium dioxide, and achieve the effect of improving photocatalytic efficiency and activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

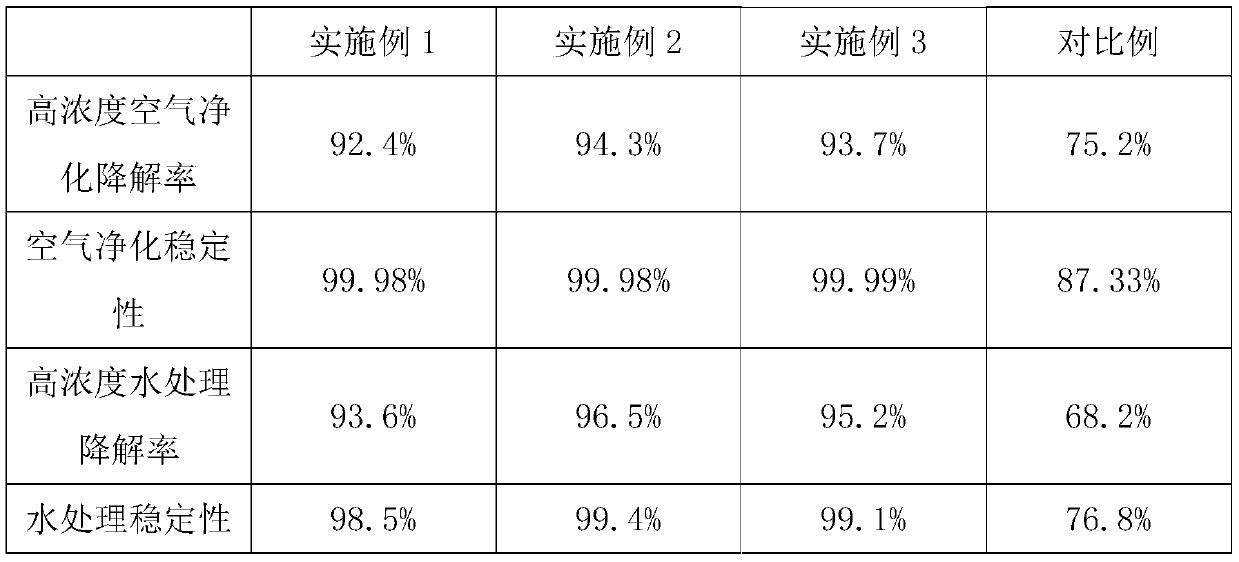

Embodiment 1

[0021] A preparation method of high-efficiency titanium-based photocatalyst, comprising the steps of:

[0022] Step 1, put the base material into distilled water and absolute ethanol in order to ultrasonically clean it for 20 minutes, and dry it to obtain a clean base material;

[0023] Step 2, adding polyvinyl alcohol into distilled water and stirring evenly to obtain a polyvinyl alcohol liquid, then immersing the base material in the polyvinyl alcohol liquid, taking it out and drying to obtain a polyvinyl alcohol film;

[0024] Step 3, spraying the nano-titanium monoxide powder on the surface of the polyvinyl alcohol film, and then spraying n-butyl titanate on the surface to obtain a multi-film substrate;

[0025] Step 4, put the multi-film substrate into a sintering kettle, seal and sinter for 2 hours to obtain a titanium-based photocatalytic film.

[0026] The ultrasonic cleaning frequency in step 1 is 50 kHz, the temperature is 40° C., and the drying temperature is 100° ...

Embodiment 2

[0032] A preparation method of high-efficiency titanium-based photocatalyst, comprising the steps of:

[0033] Step 1, put the base material into distilled water and absolute ethanol in order to ultrasonically clean it for 30 minutes, and then dry it to obtain a clean base material;

[0034] Step 2, adding polyvinyl alcohol into distilled water and stirring evenly to obtain a polyvinyl alcohol liquid, then immersing the base material in the polyvinyl alcohol liquid, taking it out and drying to obtain a polyvinyl alcohol film;

[0035] Step 3, spraying the nano-titanium monoxide powder on the surface of the polyvinyl alcohol film, and then spraying n-butyl titanate on the surface to obtain a multi-film substrate;

[0036] Step 4, put the multi-film substrate into a sintering kettle, seal and sinter for 5 hours to obtain a titanium-based photocatalytic film.

[0037] The ultrasonic cleaning frequency in step 1 is 80 kHz, the temperature is 50° C., and the drying temperature is ...

Embodiment 3

[0043] A preparation method of high-efficiency titanium-based photocatalyst, comprising the steps of:

[0044] Step 1, put the base material into distilled water and absolute ethanol in order to ultrasonically clean it for 25 minutes, and dry to obtain a clean base material;

[0045] Step 2, adding polyvinyl alcohol into distilled water and stirring evenly to obtain a polyvinyl alcohol liquid, then immersing the base material in the polyvinyl alcohol liquid, taking it out and drying to obtain a polyvinyl alcohol film;

[0046] Step 3, spraying the nano-titanium monoxide powder on the surface of the polyvinyl alcohol film, and then spraying n-butyl titanate on the surface to obtain a multi-film substrate;

[0047] Step 4, put the multi-film substrate into a sintering kettle, seal and sinter for 4 hours to obtain a titanium-based photocatalytic film.

[0048] The ultrasonic cleaning frequency in step 1 is 70 kHz, the temperature is 45° C., and the drying temperature is 110° C. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com