A kind of metal phosphide nanofiber and preparation method thereof

A metal phosphide and nanofiber technology, which is applied in the chemical characteristics of fibers, textiles and paper making, etc., can solve the problems of phosphine gas being highly toxic, endangering health, and entering phosphine gas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

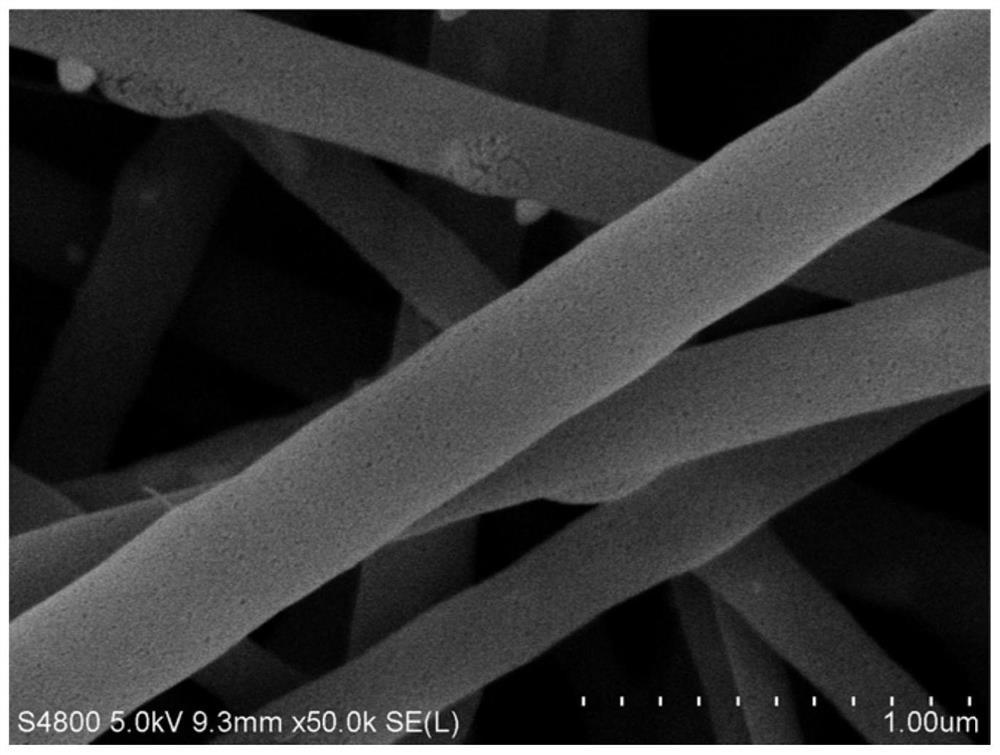

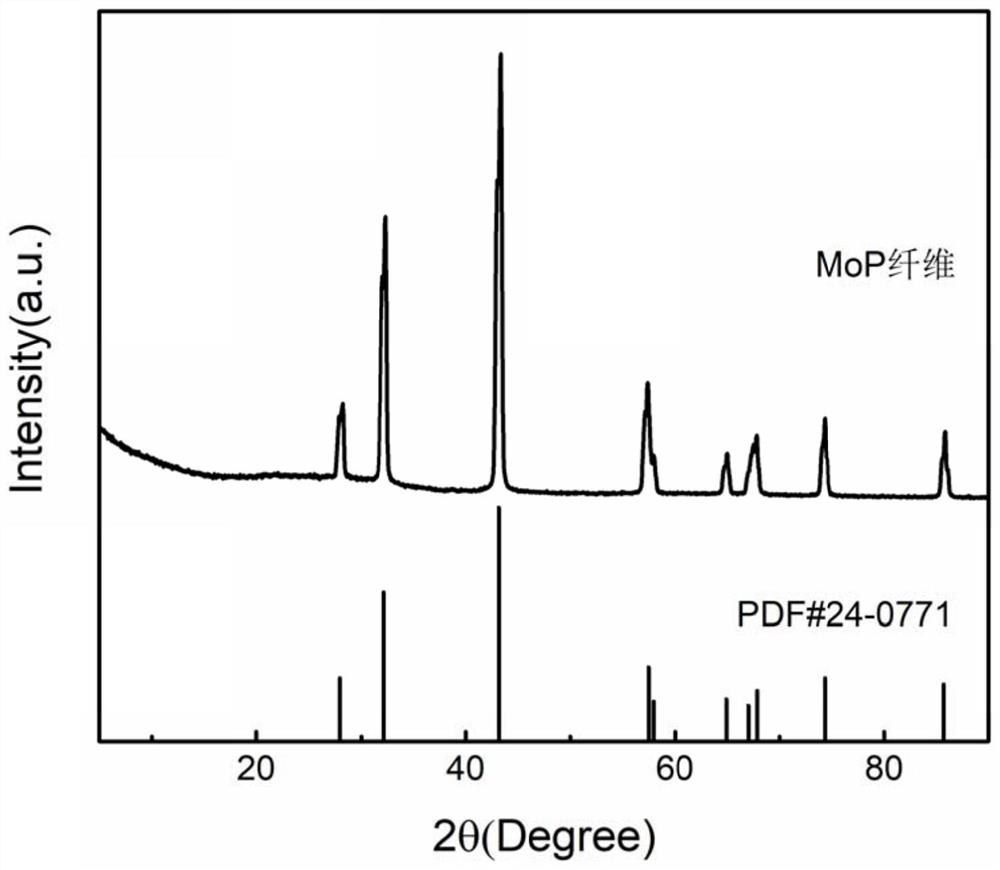

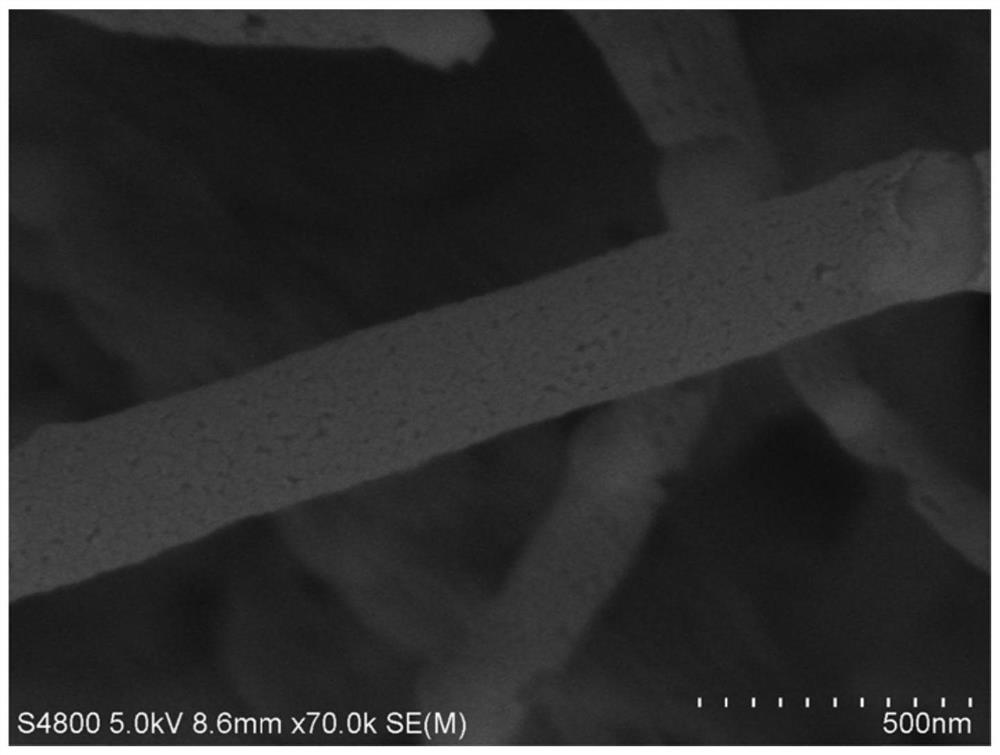

Embodiment 1

[0025] 1) Dissolve 0.8g of PVA in 10ml of deionized water, heat and stir to 70°C to form a uniform PVA solution.

[0026] 2) Get ammonium molybdate powder (H 24 Mo 7 N 6 o 24 4H 2 O) 0.883g, phytic acid 0.550g (the ratio of the amount of Mo and P is 1:1) was added to the above PVA solution together to obtain a mixed solution.

[0027] 3) Add 0.1ml Triton-X-100 surfactant to the above mixed solution, stir evenly to form spinning precursor solution.

[0028] 4) Pour the spinning precursor solution in step 3) into the syringe, debug the instrument to carry out electrospinning, the parameters of the electrospinning are: the distance from the spinning needle to the collecting plate is 15cm, the spinning voltage is 20kV, and the spinning solution Flow rate 0.3mL / h. After electrospinning, the precursor nanofibers on the plate are stripped.

[0029] 5) Heat treatment of the precursor nanofibers, the heat treatment process is: in Ar / H 2 Mixed atmosphere (volume ratio of 95% Ar ...

Embodiment 2

[0032] 1) Dissolve 0.9g of PVA in 10ml of deionized water, heat and stir to 70°C to form a uniform PVA solution.

[0033] 2) Take cobalt chloride powder (CoCl 2 ·6H 2 O) 1.189g, and 0.550g of phytic acid powder (the ratio of the amount of Co to P is 2:1) were added to the above PVA solution together to obtain a mixed solution.

[0034] 3) Add 0.05ml of Triton-X-100 surfactant into the above mixed solution, and stir evenly to form a spinning precursor solution.

[0035] 4) Pour the spinning precursor solution in step 3) into the syringe, and debug the instrument to carry out electrospinning. The parameters of the electrospinning are: the distance from the spinning needle to the collecting plate is 15cm, the spinning voltage is 20KV, and the spinning solution Flow rate 0.4mL / h. After electrospinning, the precursor nanofibers on the plate are stripped.

[0036]5) Heat treatment of the precursor nanofibers, the heat treatment process is: in Ar / H 2 Mixed atmosphere (volume rat...

Embodiment 3

[0039] 1) Dissolve 1.0g of PVA in 10ml of deionized water, heat and stir to 70°C to form a uniform PVA solution.

[0040] 2) Take nickel chloride powder (NiCl 2 ·6H 2 O) 1.188g, and 0.550g of phytic acid powder (the ratio of the amount of Ni to P is 2:1) were added to the above PVA solution together to obtain a mixed solution.

[0041] 3) Triton-X-100 surfactant with a concentration of 1ml is added to the above mixed solution, and stirred evenly to form a spinning precursor solution.

[0042] 4) Pour the spinning precursor solution in step 3) into the syringe, and debug the instrument for electrospinning. The parameters of the electrospinning are: the distance from the spinning needle to the collecting plate is 15cm, the spinning voltage is 18KV, and the spinning solution Flow rate 0.5mL / h. After electrospinning, the precursor nanofibers on the plate are stripped.

[0043] 5) Heat treatment of the precursor nanofibers, the heat treatment process is: in Ar / H 2 Mixed atmosp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com