Rare earth oxide synergistic nano-silver antibacterial agent and preparation method thereof

A rare earth oxide and nano-silver technology, which is applied in the field of antibacterial materials, can solve the problems of poor weather resistance, high antibacterial cost, and easy reduction and agglomeration, and achieve high antibacterial efficacy, high-efficiency antibacterial effect, and the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

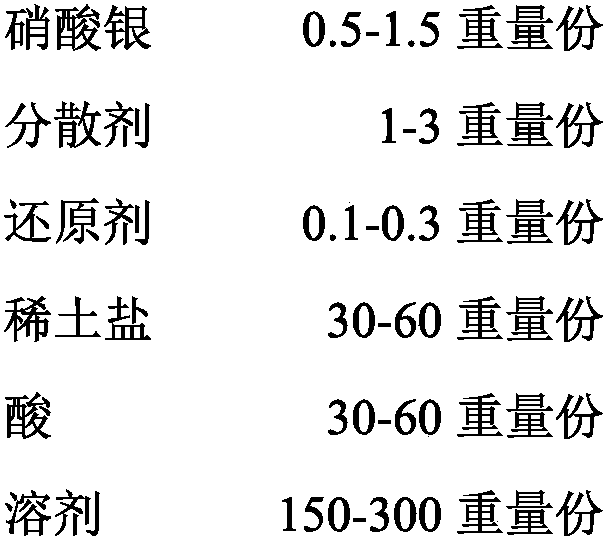

Method used

Image

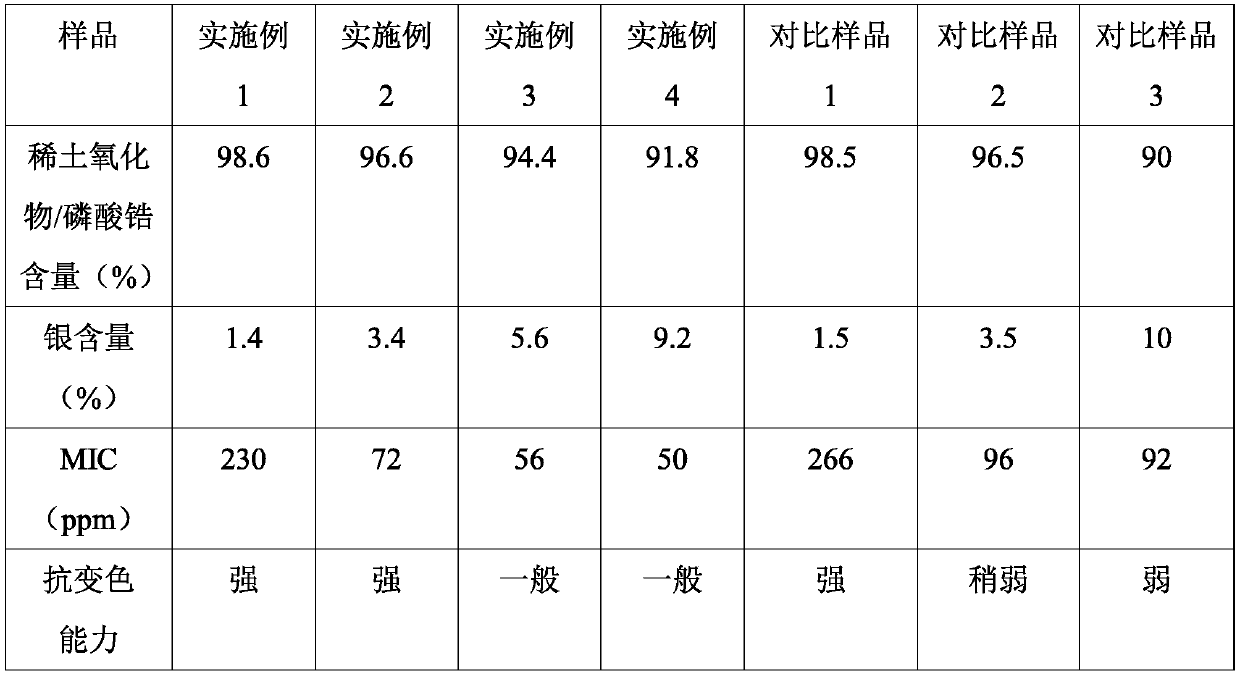

Examples

Embodiment 1

[0034] (1) 0.5g silver nitrate, 1g polyvinylpyrrolidone and 20g deionized water are mixed into the first solution, and 0.1g sodium borohydride and 10g deionized water are mixed into the second solution;

[0035] (2) Disperse the first solution evenly under magnetic stirring at 30°C, and then add the second solution dropwise to the first solution at a constant speed within 1 hour. times, to obtain nano-silver sol;

[0036] (3) 60g cerium nitrate, 60g citric acid and 250g deionized water are mixed with the third solution;

[0037] (4) The third solution was magnetically stirred at 30° C. for 3 hours to obtain a rare earth wet gel;

[0038] (5) blending and stirring the above-mentioned nano-silver sol and the above-mentioned rare earth wet gel at 40° C. for 2 hours to obtain a mixed wet gel;

[0039] (6) Dry the above mixed wet gel in a constant temperature drying oven at 150°C for 3 hours to obtain a dry gel;

[0040] (7) Put the above dry gel into a muffle furnace after crus...

Embodiment 2

[0042] (1) 1g silver nitrate, 2g chitosan and 25g deionized water are mixed into the first solution, and 0.15g ascorbic acid and 15g deionized water are mixed into the second solution;

[0043] (2) Stir the first solution at 30°C to disperse evenly, and then add the second solution dropwise to the first solution at a constant speed within 1.5 hours. After the addition, keep it warm for 3 hours, and then wash it centrifugally with deionized water. 3 times to obtain nano-silver sol;

[0044] (3) 40g neodymium sulfate, 40g zinc citrate and 150g deionized water are mixed with the third solution;

[0045] (4) The third solution was magnetically stirred at 15° C. for 2 hours to obtain a rare earth wet gel;

[0046] (5) blending and stirring the above-mentioned nano-silver sol and the above-mentioned rare earth wet gel at 15° C. for 1 hour to obtain a mixed wet gel;

[0047] (6) Dry the above mixed wet gel in a constant temperature drying oven at 120°C for 2 hours to obtain a dry g...

Embodiment 3

[0050] (1) 1g silver nitrate, 2g chitosan and 25g deionized water are mixed into the first solution, and 0.15g sodium biborate and 15g deionized water are mixed into the second solution;

[0051] (2) Stir the first solution at 30°C to disperse evenly, and then add the second solution dropwise to the first solution at a constant speed within 1.5 hours. After the addition, keep it warm for 3 hours, and then wash it centrifugally with deionized water. 3 times to obtain nano-silver sol;

[0052] (3) 30g lanthanum nitrate, 30g citric acid and 180g deionized water are mixed with the third solution;

[0053] (4) The third solution was magnetically stirred at 60° C. for 4 hours to obtain a rare earth wet gel;

[0054] (5) blending and stirring the above-mentioned nano-silver sol and the above-mentioned rare earth wet gel at 100° C. for 4 hours to obtain a mixed wet gel;

[0055] (6) drying the above mixed wet gel in a constant temperature drying oven at 200°C for 4 hours to obtain a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com