Preformed dental crown and preparation process thereof

A dental crown, prefabricated technology, applied in dental preparations, dentistry, dental prostheses, etc., can solve the problems of inability to chew hard food, wear resin teeth, affect the patient experience, etc., to improve biological adaptability, wear resistance, etc. The effect of improving performance and improving biological fitness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

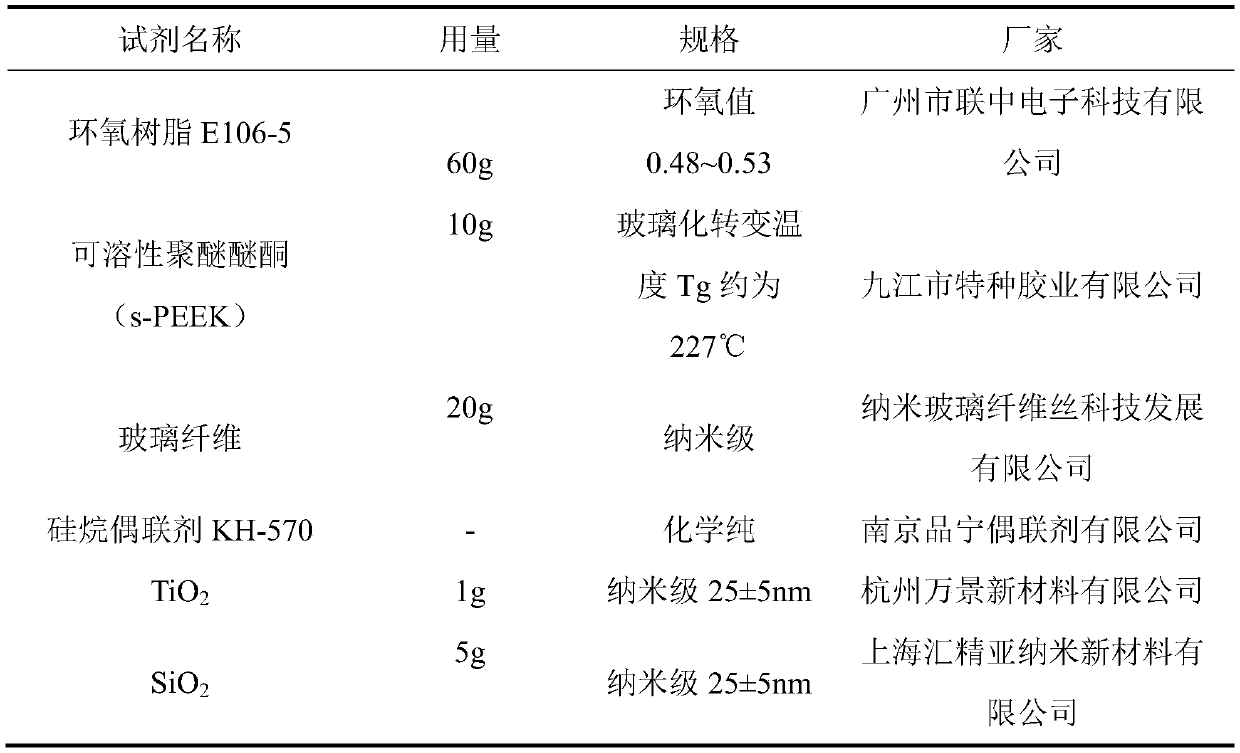

[0023] The raw materials used are shown in Table 1 below

[0024] Table 1

[0025]

[0026] Nano SiO 2 Before mixing with the resin matrix, it is necessary to use the silane coupling agent KH-570 for surface treatment, by changing the SiO 2 The original properties of the surface can reduce nano-SiO 2 The tendency to agglomerate, increase its dispersibility in the resin organic phase, such as unmodified nano SiO 2 The size of agglomerates is mainly distributed between 150~600nm, after modification, nano SiO 2 The size of the agglomerates is mainly distributed between 50~150nm, indicating that nano SiO 2 The hydroxyl groups on the surface are replaced by organic functional groups, reducing the tendency to agglomerate. (Similarly, suitable for TiO 2 )

[0027] The comprehensive performance of the composite material has been significantly improved.

[0028] The operation process is as follows: Nano SiO 2 And TiO 2 Add it to the mixed solution of absolute ethanol / water with a volume ratio ...

Embodiment 2

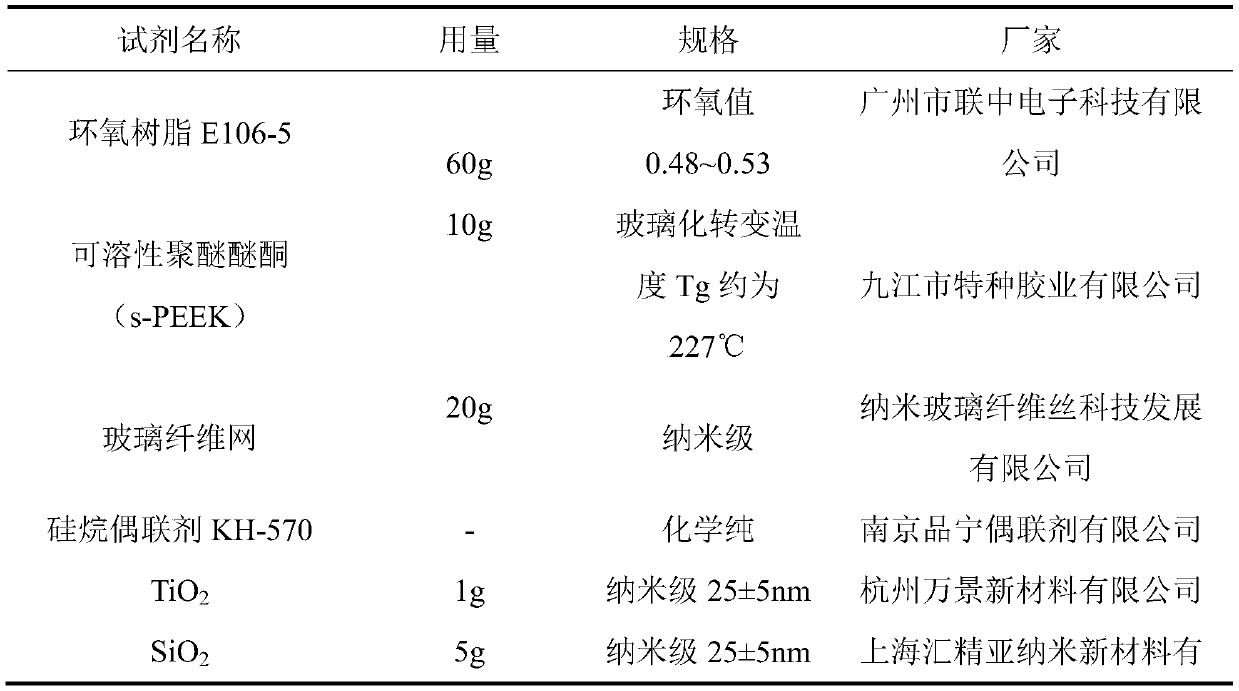

[0034] The raw materials used are shown in Table 2 below

[0035] Table 2

[0036]

[0037]

[0038] Nano SiO 2 Before mixing with the resin matrix, it is necessary to use the silane coupling agent KH-570 for surface treatment, by changing the SiO 2 The original properties of the surface can reduce nano-SiO 2 The tendency to agglomerate increases its dispersibility in the resin organic phase.

[0039] The operation process is as follows: Nano SiO 2 And TiO 2 Add it to the mixed solution of absolute ethanol / water with a volume ratio of 2:1 and fully disperse it under high-speed shearing at 3500r / min. After the dispersion is uniform, add a 30% mass fraction KH-570 solution and use The pH value of the oxalic acid solution was adjusted to about 4, the shear rate was adjusted to 2000r / min, and the reaction temperature was 70°C. After 3 hours of reaction, the stirring was stopped. The obtained nano suspension was suction filtered, and the filter cake was ultrasonically cleaned with a mixt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com