A kind of adsorbent and its preparation method and application

A technology of adsorbent and molecular sieve, which is applied in the field of chemical materials, can solve problems such as difficult to meet the selective separation requirements of methane/nitrogen adsorption, and achieve the effects of high-efficiency adsorption and separation performance, reduced surface polarity, and reduced cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

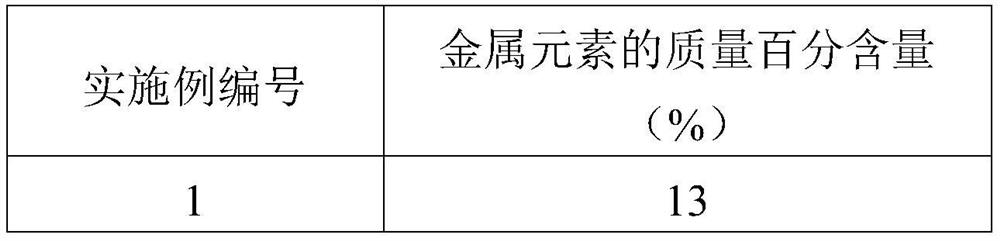

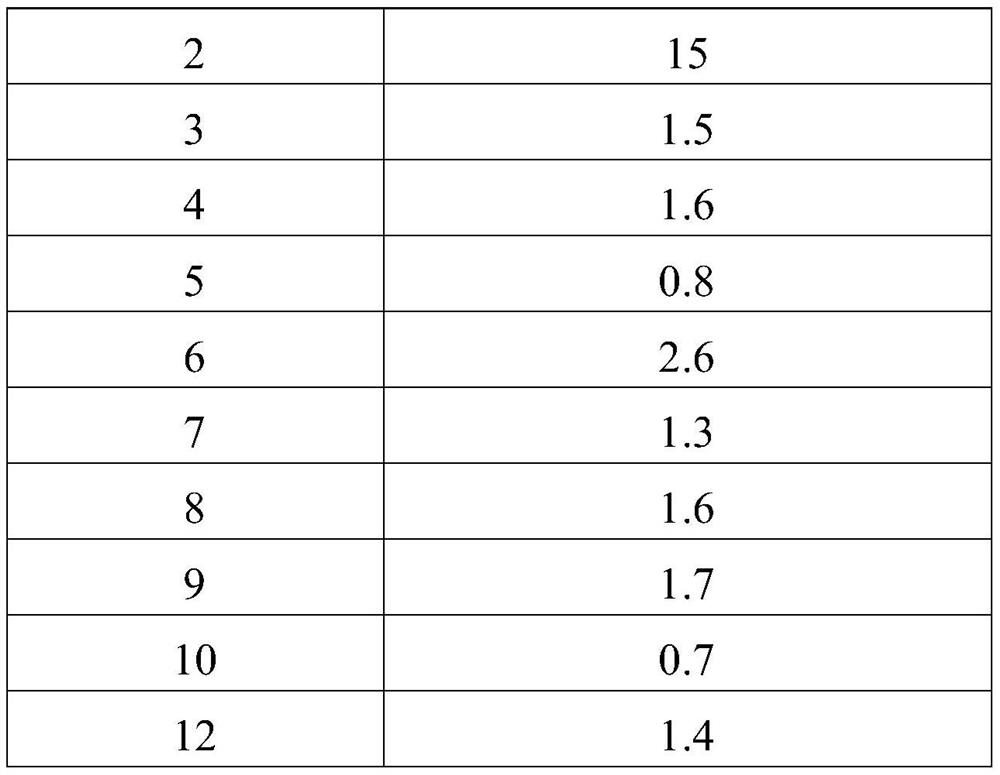

Embodiment 1

[0054] First, 10 g of FAU-type 13X molecular sieves were ion-exchanged with 400 ml of 1M zinc nitrate aqueous solution for 2 hours in a water bath at 60° C., washed and dried. The exchanged molecular sieve was reacted with 14 g of 2-methylimidazole at 60°C for 4 hours, washed with deionized water until neutral, and dried to obtain an adsorbent, marked as 1#. Under the conditions of 25°C and 100KPa, the CH of the obtained product 4 and N 2 The adsorption capacity is 5.42cm 3 / g and 1.47cm 3 / g, the equilibrium separation ratio of methane and nitrogen is 3.69.

Embodiment 2

[0056] First, 10 g of FAU-type Na-Y molecular sieves were ion-exchanged with 400 ml of a 1M copper chloride aqueous solution for 4 hours in a water bath at 60° C., washed and dried. The exchanged molecular sieves were reacted with 16 g of 2-ethylimidazole at 60°C for 4 hours, washed with deionized water until neutral, and dried to obtain an adsorbent, marked as 2#. Under the conditions of 25°C and 100KPa, the CH of the obtained product 4 and N 2 The adsorption capacity is 5.29cm 3 / g and 1.46cm 3 / g, the equilibrium separation ratio of methane and nitrogen is 3.62.

Embodiment 3

[0058] First, 10 g of MOR molecular sieves were ion-exchanged with 400 ml of a 1M indium nitrate aqueous solution for 8 hours in a water bath at 50° C., washed and dried. The exchanged molecular sieves were reacted with 18 g of 2-ethylimidazole at 60°C for 4 hours, washed with deionized water until neutral, and dried to obtain an adsorbent, marked as 3#. Under the conditions of 25°C and 100KPa, the CH of the obtained product 4 and N 2 The adsorption capacity is 10.04cm 3 / g and 2.56cm 3 / g, the equilibrium separation ratio of methane and nitrogen is 3.92.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com