Separation method of hawthorn fruit juice and pectin and brewing method of hawthorn fruit wine

A separation method and technology for hawthorn fruit wine are applied in the brewing of hawthorn fruit wine, the separation of pectin, and the fields of hawthorn juice, which can solve the problem that the flavor and nutrients of hawthorn cannot be well preserved, and the comprehensive utilization of hawthorn juice and pectin cannot be achieved. It is not possible to comprehensively utilize hawthorn wine and other problems to achieve the effects of protecting the fruity aroma and nutrients of the juice, improving the harmony between sweet and sour, and improving the fermentation capacity of yeast.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

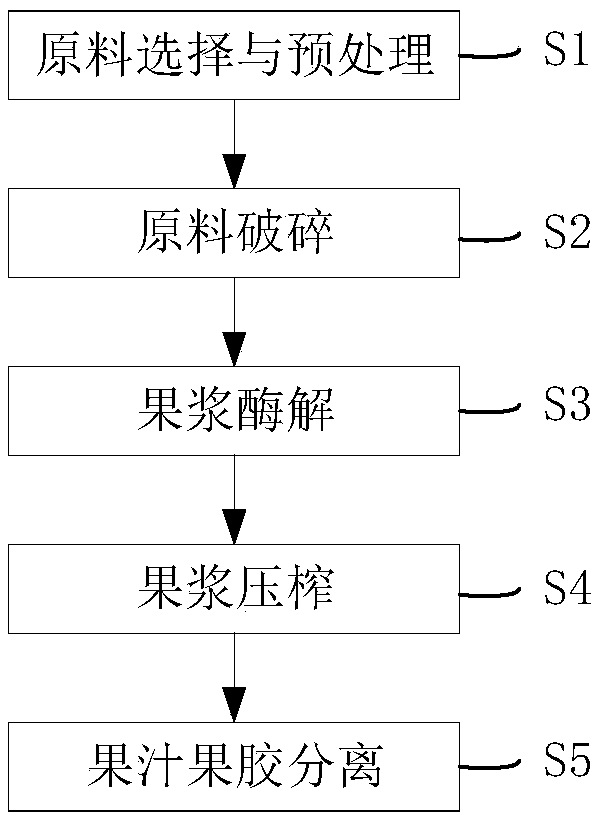

[0076] Separation method of hawthorn fruit juice and pectin:

[0077] (1) Raw material selection and pretreatment: select fresh, complete, and highly mature hawthorn fruits as raw materials, wash the selected hawthorn with pure water until the cleaning water is clear, and remove some microorganisms and dust attached to the surface of the hawthorn, etc. Pollutants, fish out.

[0078] (2) Raw material crushing: mix according to the ratio of pure water: hawthorn=1:1.5, add a beater, spray 75ppm ascorbic acid and 80ppm potassium metabisulfite aqueous solution in the beating process, store in a stainless steel insulation tank after pulping, During the conveying process, a quick cooling machine is used for rapid cooling, and the pulp is stored at a temperature of 10°C.

[0079] (3) Enzymolysis of pulp: add low-temperature pectinase to the pulp obtained in step S2, so that the pulp is subjected to enzymolysis at a temperature of 10° C.; the content of the added low-temperature pecti...

Embodiment 2

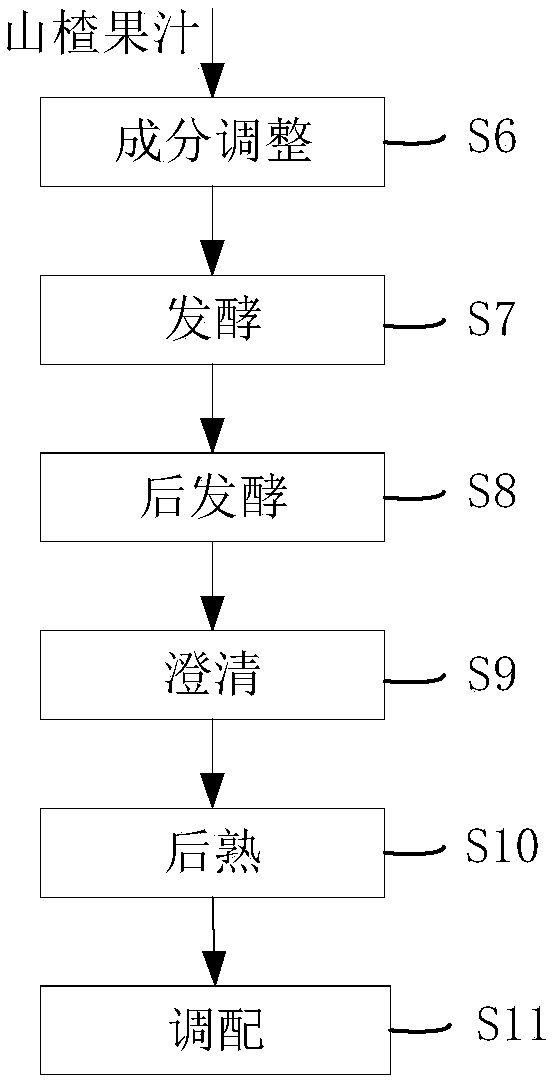

[0084] How to make hawthorn fruit wine:

[0085] (1) Component adjustment: use the hawthorn fruit juice obtained in Example 1 as raw material, detect the total sugar content of the hawthorn fruit juice, and add white granulated sugar and glucose monohydrate in a weight ratio of 1:1 according to the total sugar 220g / L to replenish the hawthorn fruit juice In, and add 80ppm of potassium metabisulfite.

[0086] (2) Fermentation: fill the 2 / 3 of the fermenter with the hawthorn fruit juice with adjusted sugar, add activated active Saccharomyces cerevisiae, the amount of active Saccharomyces cerevisiae added is 180g / t, and the fermentation temperature is kept at 15-22 ℃, the main fermentation is about 30 days; when the residual sugar in the fruit juice is less than 5g / L, the main fermentation is over, the tank is poured, the wine lees is drained, and the supernatant is post-fermented.

[0087] (3) Post-fermentation: The clarified fruit wine with lees drained is stored in stainless ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com