Novel catalyst for synthesizing biodiesel and application method of novel catalyst

A technology for synthesizing organisms and catalysts, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, heterogeneous catalyst chemical elements, etc., and can solve environmental pollution, equipment corrosion, sulfur content increase. High problems, to achieve the effect of improving product purity, less corrosiveness, and high production safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

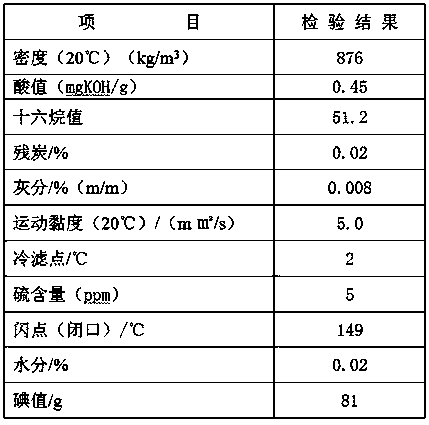

Embodiment 1

[0030] Embodiment 1 A kind of synthetic biodiesel novel catalyst and its application

[0031] 1. Feeding

[0032] Add kitchen waste oil raw materials into the reaction kettle, heat up to 60°C; start stirring, add glycerin raw materials, and stir and mix at a speed of 240r / min for 15 minutes;

[0033] The consumption of described glycerol is 10% of kitchen waste oil quality;

[0034] 2. Esterification reaction

[0035] Add an esterification catalyst into the kettle, gradually raise the temperature to 250°C at a heating rate of 20°C / min, and start the esterification reaction;

[0036] The esterification catalyst is composed of zinc oxide with a purity of 99% and a mesh number of 400;

[0037] Described esterification catalyst, its consumption accounts for 1% of kitchen waste oil quality;

[0038] 3. Central control detection:

[0039] During the esterification reaction, samples are taken every 2 hours, and the acid value of the product is measured by acid-base titration met...

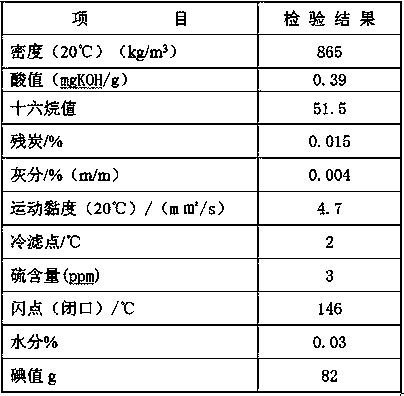

Embodiment 2

[0065] Embodiment 2 A novel catalyst for synthesizing biodiesel and its application

[0066] 1. Feeding

[0067] Add the kitchen waste oil raw material into the reaction kettle, raise the temperature to 60-65°C; start stirring, add the glycerin raw material at a speed of 240r / min, and stir and mix for 15 minutes;

[0068] The add-on of described glycerin is 13% of kitchen waste oil quality;

[0069] 2. Esterification reaction

[0070] Add an esterification catalyst into the kettle, gradually raise the temperature to 250°C at a heating rate of 20°C / min, and start the esterification reaction;

[0071] The esterification catalyst is composed of modified composite zinc oxide solid particles with a relative density of 5.92 and a mesh number of 200 mesh;

[0072] The raw material composition of the esterification catalyst, in parts by weight, includes: 10 parts of zinc oxide, 5 parts of zinc permanganate, 0.5 parts of cerium oxide, and 4 parts of tetramethoxysilane;

[0073] The...

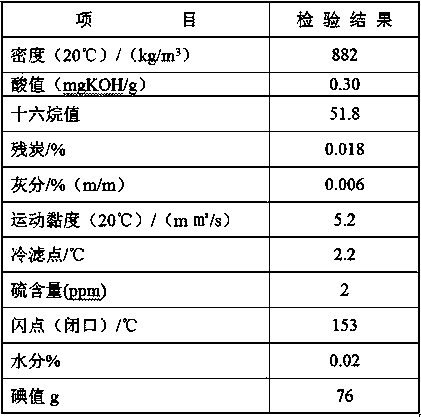

Embodiment 3

[0102] Embodiment 3 A kind of synthetic biodiesel novel catalyst and its application

[0103] 1. Feeding

[0104] Add the kitchen waste oil raw material into the reaction kettle, raise the temperature to 65°C; start stirring, add the glycerin raw material at a speed of 240r / min, and stir and mix for 15 minutes;

[0105] The add-on of described glycerin is 13% of kitchen waste oil quality;

[0106] 2. Esterification reaction

[0107] Add an esterification catalyst into the kettle, gradually raise the temperature to 260°C at a heating rate of 20°C / min, and start the esterification reaction;

[0108] The esterification catalyst is composed of modified composite zinc oxide solid particles with a relative density of 6.10 and a mesh number of 400 mesh;

[0109] The raw material composition of the esterification catalyst, in parts by weight, includes: 6 parts of zinc oxide, 5 parts of zinc permanganate, 2 parts of cerium oxide, and 2 parts of tetramethoxysilane;

[0110] The prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com