Arc additive manufacturing method

A technology of additive manufacturing and electric arc, which is applied in the field of additive manufacturing, can solve the problems of increased workload and the inability to accurately control the machining allowance, and achieve the effect of ensuring surface quality, reducing machining allowance, and freely controlling the forming width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

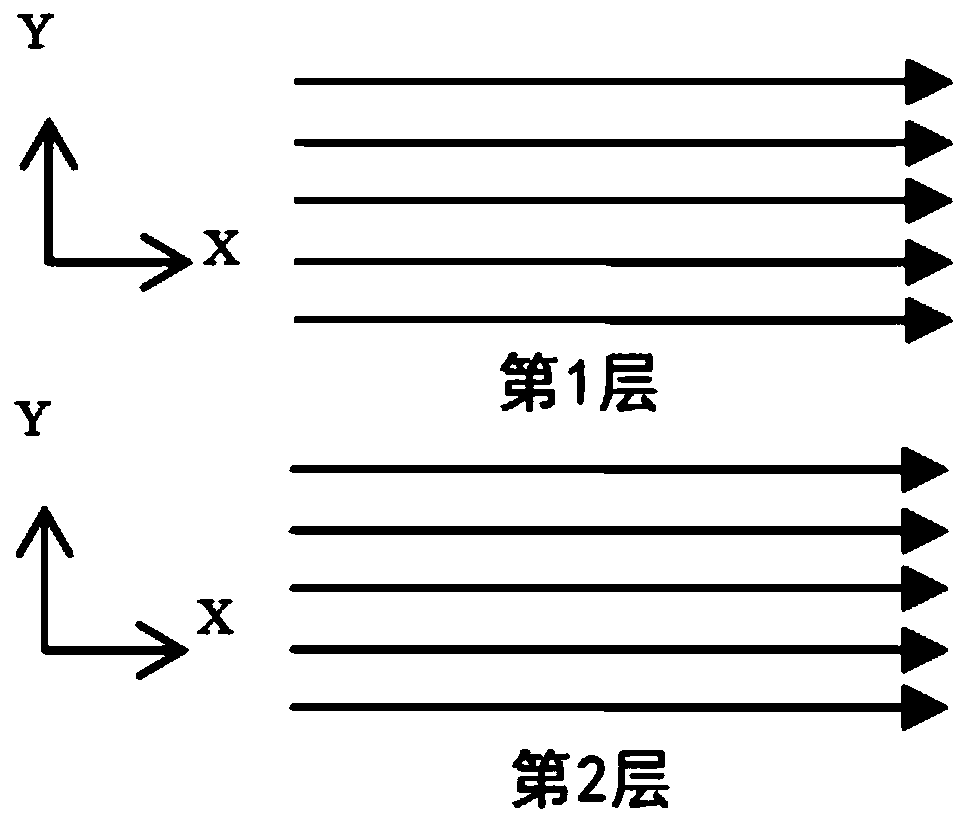

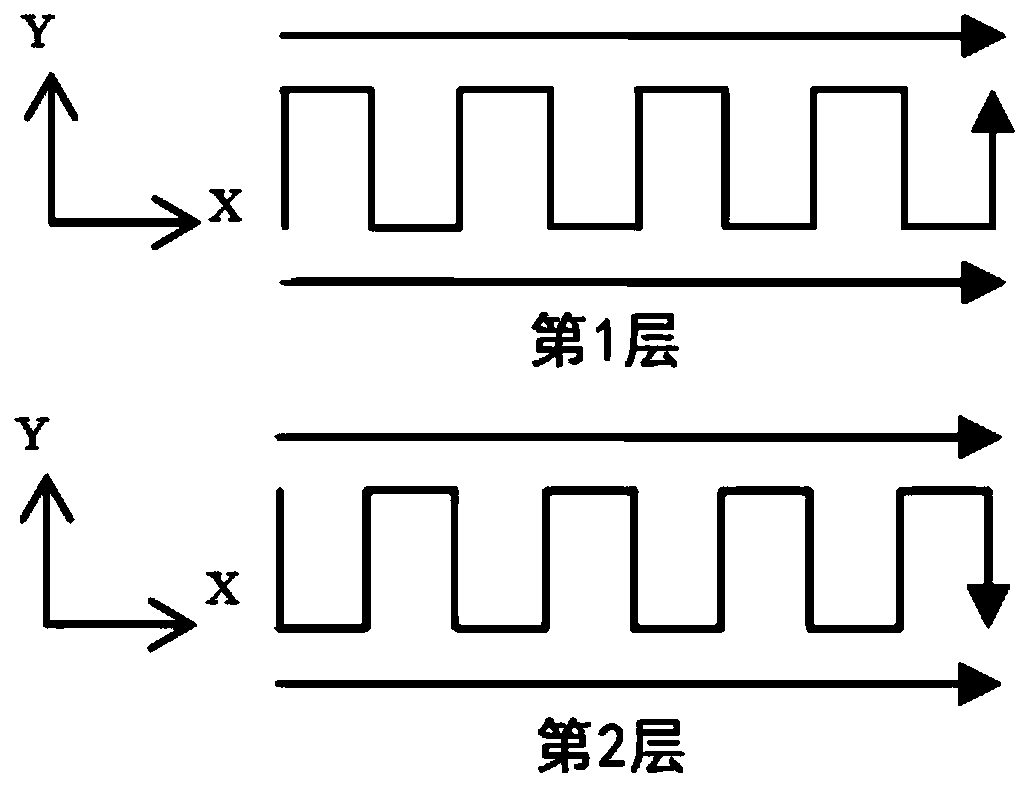

Method used

Image

Examples

Embodiment 1

[0042] Example 1: When it is necessary to process additive manufacturing of 24mm thick stainless steel rectangular structural parts, a compound path combining straight paths on both sides and a triangular broken line path is used for forming. The working parameters are low-frequency pulse frequency 10-30Hz, and base value current 150- 200A, pulse current 90A, duty cycle 50%, ultra-audio pulse frequency 20-60kHz, current 60-90A, wire feeding speed 180-300cm / min, welding speed 20-40cm / min, single bead width 10mm, extra processing Measure one side 1mm, height 1.1-1.5mm; triangular broken line path width 14mm, overlap 4mm; use high-purity argon for frontal protection, flow (15-25) L / min; according to figure 2 Arc additive path and forming process parameters Cyclic arc additive forming to obtain a superalloy structural part blank with a length of 180mm, a width of 26mm, and a height of 50mm, with a machining allowance of 1mm on one side.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Overall width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Overall width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com