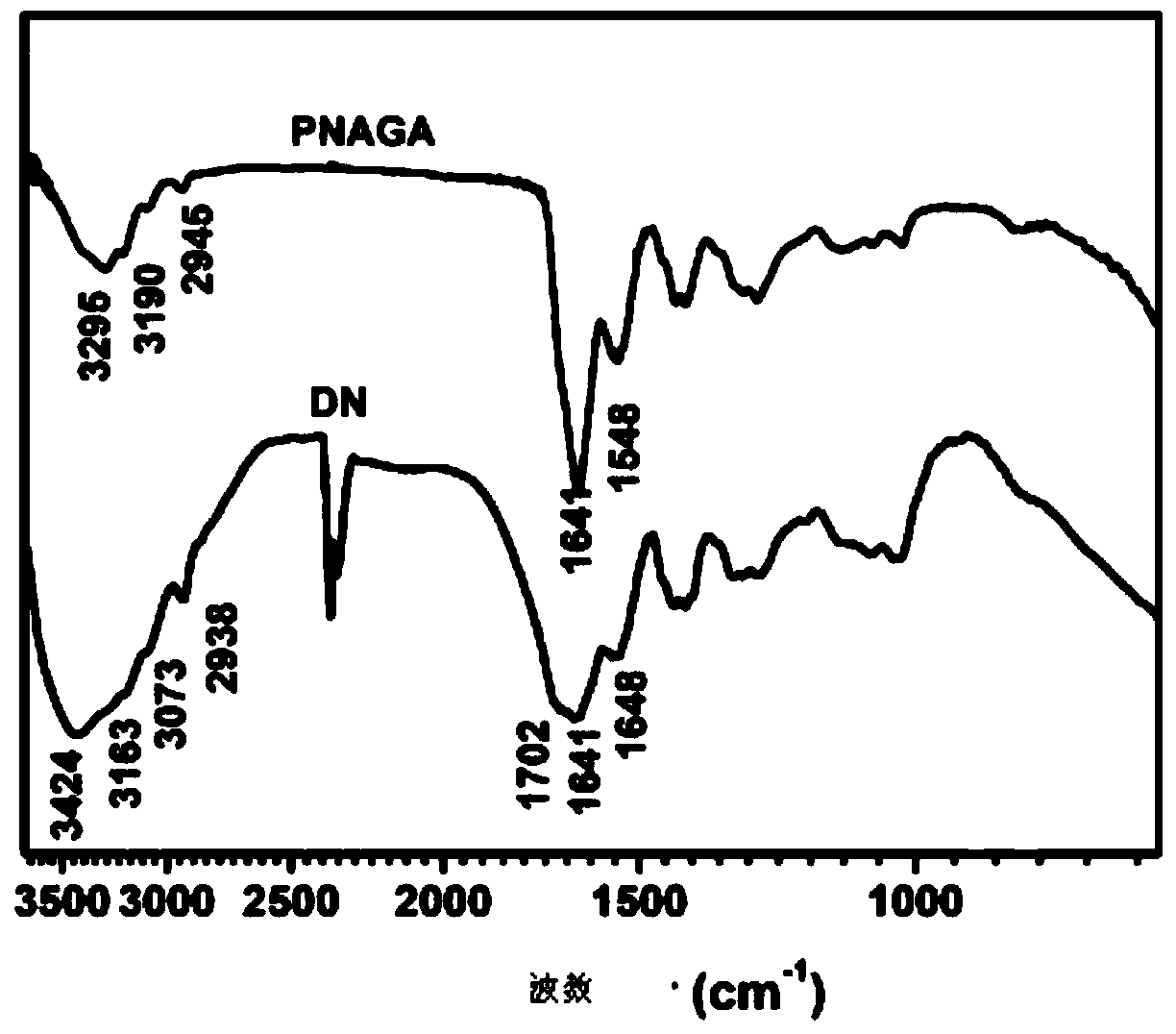

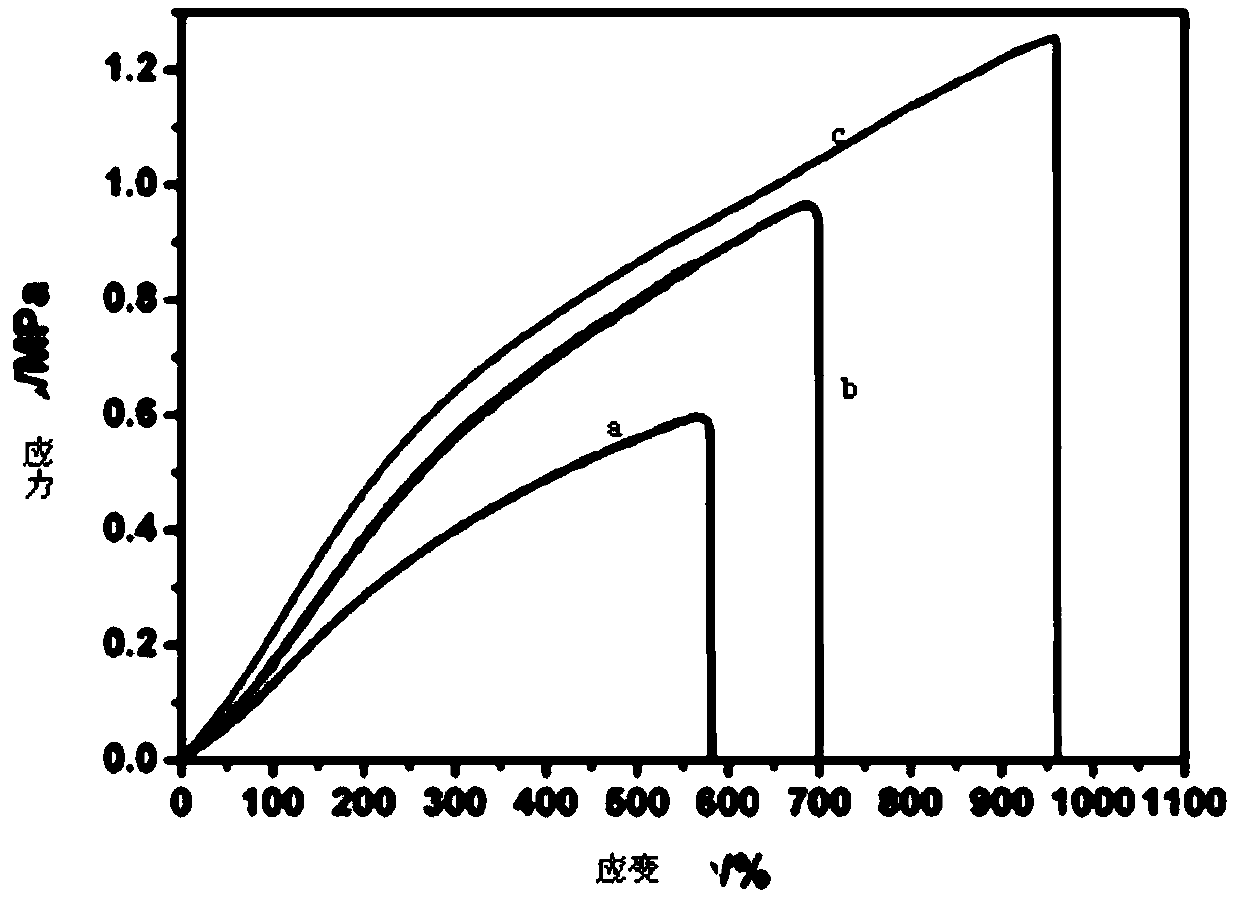

Double-network hydrogel based on poly-N-acrylylglycinamide and sodium alginate, and preparation method thereof

A technology of polyacryloyl glycinamide and acryloyl glycinamide, which is applied in the field of double network hydrogel based on polyacryloyl glycinamide and sodium alginate and its preparation, can solve the problem of weak mechanical properties of hydrogel, Low energy dissipation mechanism, hydrogel application limitations and other issues, to achieve the effect of broadening the preparation method and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Step 1, put 6.0g of glycinamide hydrochloride, 6mL of deionized water, 32mL of 2mol / L potassium carbonate and 16mL of diethyl ether in a reaction vessel and mix in an ice bath, then mix 5.0g of acryloyl chloride with 20mL of diethyl ether and slowly drop Added to the above reaction solution, the dropwise addition time was 0.5h, and then stirred and reacted under ice bath for 3h after the dropwise addition, the pH of the reaction solution was adjusted to 1, after washing with ether, the pH of the reaction solution was adjusted to 6, and the The reaction solution was freeze-dried, washed with ethanol / methanol mixed solvent (the ratio of ethanol to methanol was 4:1), rotary evaporated, and dried to obtain acryloyl glycinamide (NAGA);

[0022] Step 2, dissolve 0.171 g of acryloyl glycinamide (NAGA) and 0.029 g of sodium alginate (alginate) obtained above into 800 μL of water to obtain a mixed solution of acryloyl glycinamide (NAGA) and sodium alginate (alginate) , the mass ...

Embodiment 2

[0024] Step 1, put 7.0g of glycinamide hydrochloride, 6mL of deionized water, 35mL of 2mol / L potassium carbonate and 20mL of diethyl ether in a reaction vessel and mix in an ice bath, then mix 6.5g of acryloyl chloride with 30mL of diethyl ether and slowly drop Add it to the above reaction solution, and the dropwise addition time is 1.5h. After the dropwise addition, stir and react in an ice bath for 5h, and adjust the pH of the reaction solution to 3. After washing with ether, adjust the pH of the reaction solution to 7. The reaction solution was freeze-dried, washed with ethanol / methanol mixed solvent (the ratio of ethanol to methanol was 4:1), rotary evaporated, and dried to obtain acryloyl glycinamide (NAGA);

[0025] Step 2, dissolve 0.178g of acryloyl glycinamide (NAGA) and 0.022g of sodium alginate (alginate) obtained above into 800 μL of water to obtain a mixed solution of acryloyl glycinamide (NAGA) and sodium alginate (alginate) , the mass ratio of acryloyl glycinami...

Embodiment 3

[0027]Step 1, put 6.3g of glycinamide hydrochloride, 6mL of deionized water, 33.6mL of 2mol / L potassium carbonate and 18mL of diethyl ether in a reaction vessel and mix in an ice bath, then mix 5.7g of acryloyl chloride with 24mL of diethyl ether and slowly Add dropwise into the above reaction solution, the dropwise time is 1h, and then stir and react under ice bath for 4h, adjust the pH of the reaction solution to 2, after washing with ether, adjust the pH of the reaction solution to 7, and then The reaction solution was freeze-dried, washed with ethanol / methanol mixed solvent (the ratio of ethanol to methanol was 4:1), rotary evaporated, and dried to obtain acryloyl glycinamide (NAGA);

[0028] Step 2, dissolving 0.182 g of acryloyl glycinamide (NAGA) and 0.018 g of sodium alginate (alginate) obtained above into 800 μL of water to obtain a mixed solution of acryloyl glycinamide (NAGA) and sodium alginate (alginate) , the mass ratio of acryloyl glycinamide (NAGA) to sodium al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com