Heat treatment clarification method of industrial enzyme liquid

An industrial, enzyme solution technology, applied in the direction of biochemical equipment and methods, enzymes, enzymes, etc., can solve the problems of water pollution, easily polluted water, stimulation, etc., and achieve the effect of simple process, good promotion value and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A heat treatment clarification method for industrial enzyme liquid, comprising the following steps:

[0044] (1) Select the target protein for cultivation and fermentation:

[0045] Dehydrogenase is selected as the target protein, fermented according to the existing fermentation production process to obtain a fermentation liquid, and then the fermentation liquid is subjected to cell crushing treatment through a homogenizer to obtain a cell crushing liquid;

[0046] (2) heat treatment clarification:

[0047] Carry out heat treatment and clarification to the cell disruption solution obtained in step (1), and the heat treatment clarification is:

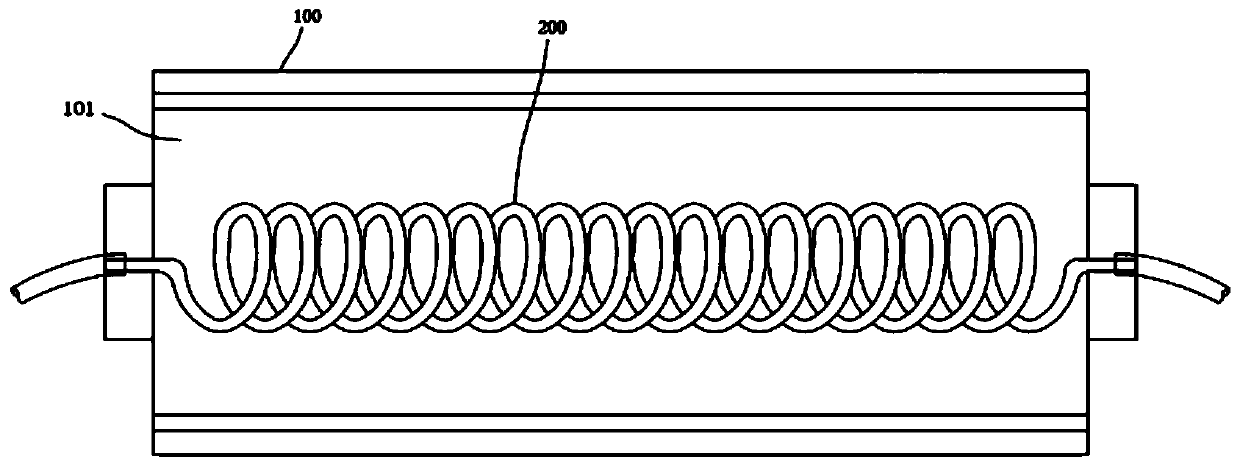

[0048] like figure 1 As shown, the cell disruption solution is passed through a serpentine tube 200 placed in the water bath heating tank 100 at a constant speed (the diameter of the pipe is 5.5mm, and the total length is 1.4m), and the constant temperature circulating hot water 101 is passed into the water bath heating tank 10...

Embodiment 2

[0053] A heat treatment clarification method for industrial enzyme liquid, comprising the following steps:

[0054] (1) Select the target protein for cultivation and fermentation:

[0055] Dehydrogenase is selected as the target protein, fermented according to the existing fermentation production process to obtain a fermentation liquid, and then the fermentation liquid is subjected to cell crushing treatment through a homogenizer to obtain a cell crushing liquid;

[0056] (2) heat treatment clarification:

[0057] Carry out heat treatment and clarification to the cell disruption solution obtained in step (1), and the heat treatment clarification is:

[0058] Pass the cell disruption liquid through a U-shaped pipe placed in a water bath heating tank at a constant speed (the diameter of the pipe is 5.5mm, and the total length is 1.4m), control the temperature in the U-shaped pipe to 80°C, and control the flow rate of the cell disruption liquid so that Its passage time in the U...

Embodiment 3

[0063] A heat treatment clarification method for industrial enzyme liquid, comprising the following steps:

[0064] (1) Select the target protein for cultivation and fermentation:

[0065] Dehydrogenase is selected as the target protein, fermented according to the existing fermentation production process to obtain a fermentation liquid, and then the fermentation liquid is subjected to cell crushing treatment through a homogenizer to obtain a cell crushing liquid;

[0066] (2) heat treatment clarification:

[0067] Carry out heat treatment and clarification to the cell disruption solution obtained in step (1), and the heat treatment clarification is:

[0068] Pass the cell disruption liquid through a section of W-shaped pipe placed in a water bath heating tank at a constant speed (the diameter of the pipe is 5.5mm, and the total length is 1.4m). Its passage time in the W-shaped pipeline is 24s;

[0069] (3) Post-processing:

[0070] Centrifuge the heat-treated and clarified...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com