Preparation method of ultralow-temperature electronic cigarette lithium ion battery

A technology of lithium-ion batteries and electronic cigarettes, which is applied to battery electrodes, secondary batteries, circuits, etc., can solve the problems of reduced battery discharge capacity, increased battery internal resistance, and unusable batteries, so as to inhibit decomposition and optimize the ratio Composition, effect of stabilizing material structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

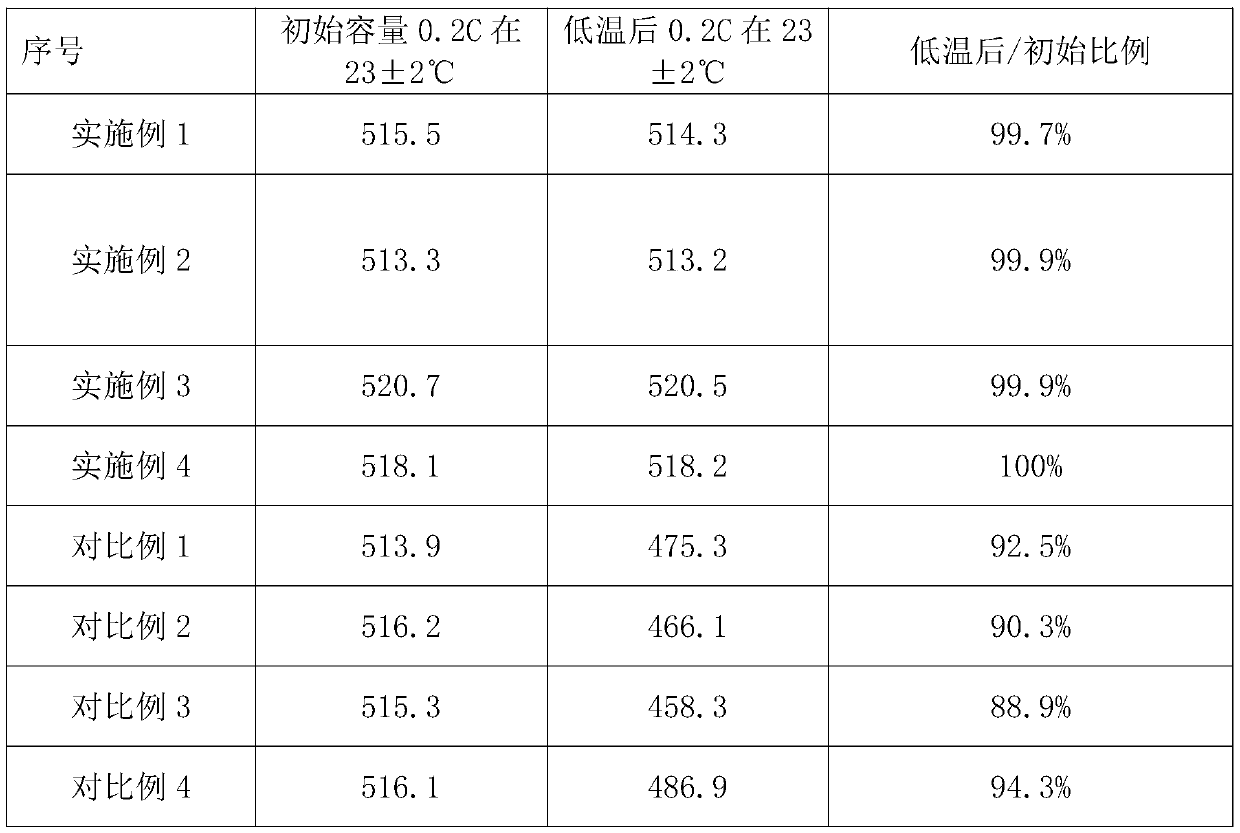

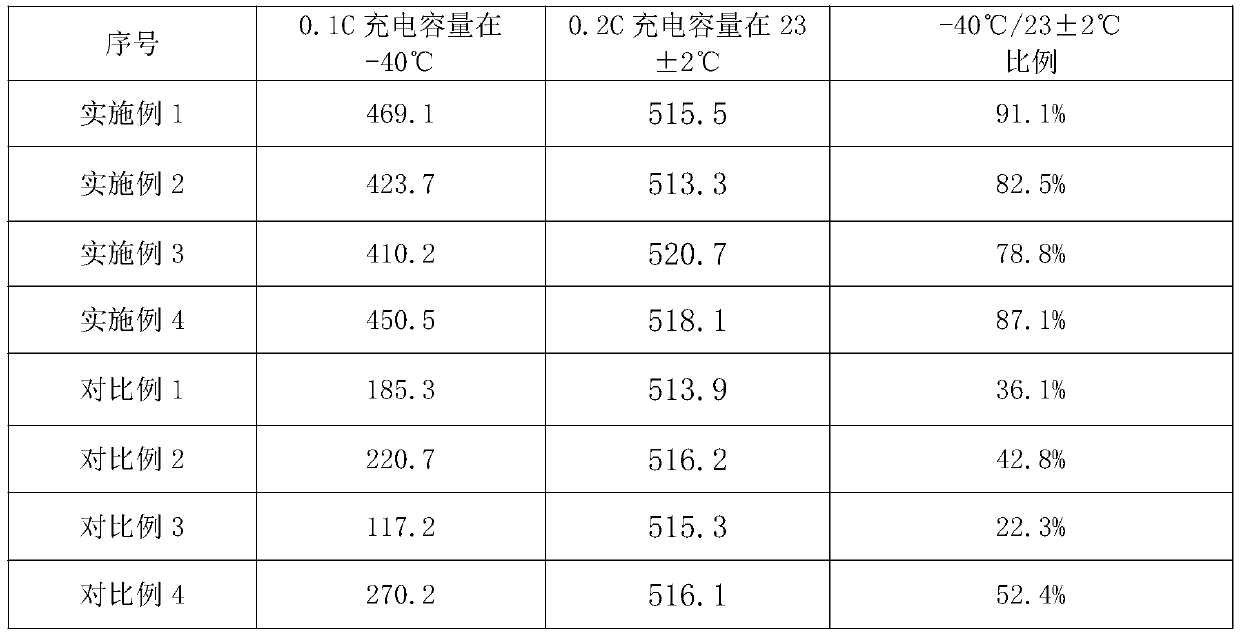

Examples

Embodiment 2

[0043] A method for preparing an ultra-low temperature soft-packaged electronic cigarette lithium-ion battery. The specific preparation process is the same as that of Example 1, but the artificial graphite used in the negative electrode is optimized and screened negative electrode particles, and the proportion of negative electrode particles with a particle size of 10-12 microns is 80%. %, and mixed with 10% negative electrode particles with a particle size of 3-5 microns, and 10% negative electrode particles with a particle size of 25-28 microns;

[0044] At the same time, the composition of the electrolyte is different, and the electrolyte includes solvent, lithium salt and additives;

[0045] The electrolyte solvent is composed of 30% ethylene carbonate by weight, 15% dimethyl carbonate by weight, 25% ethyl methyl carbonate by weight, and 35% dibutyl carbonate by weight;

[0046] The additive is composed of 5% by weight of vinylene carbonate and 3% by weight of 1-ethyl-3-me...

Embodiment 3

[0049] A method for preparing an ultra-low temperature soft-packaged electronic cigarette lithium-ion battery, the specific preparation process is the same as that of Example 1, but the artificial graphite used for the negative electrode is optimized and screened negative electrode particles, and the negative electrode particles with a particle size of 10-12 microns account for 70% , and mixed with 10% negative electrode particles with a particle size of 3-5 microns, and 20% negative electrode particles with a particle size of 25-28 microns;

[0050] The electrolyte used is composed of solvent, lithium salt and additives;

[0051] The electrolyte solvent is composed of 25% ethylene carbonate by weight, 10% dimethyl carbonate by weight, 20% ethyl methyl carbonate by weight, and 30% dibutyl carbonate by weight;

[0052] The additive is composed of 3% by weight of vinylene carbonate and 5% by weight of 1-ethyl-3-methylimidazolium tetrafluoroborate;

[0053] The lithium salt is a...

Embodiment 4

[0055] A preparation method of ultra-low temperature flexible packaging electronic cigarette lithium-ion battery, the specific preparation process is the same as that of Example 1, but the artificial graphite used for the negative electrode is optimized and screened negative electrode particles, and the negative electrode particles with a particle size of 10-12 microns account for 75% , and mixed with 15% negative electrode particles with a particle size of 3-5 microns, and 10% negative electrode particles with a particle size of 25-28 microns;

[0056] The electrolyte used is composed of solvent, lithium salt and additives;

[0057] The electrolyte solvent is composed of 20% ethylene carbonate by weight, 10% dimethyl carbonate by weight, 20% ethyl methyl carbonate by weight, and 30% dibutyl carbonate by weight;

[0058] The additive is composed of 3% by weight of vinylene carbonate and 3% by weight of 1-ethyl-3-methylimidazolium tetrafluoroborate;

[0059] The lithium salt i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com