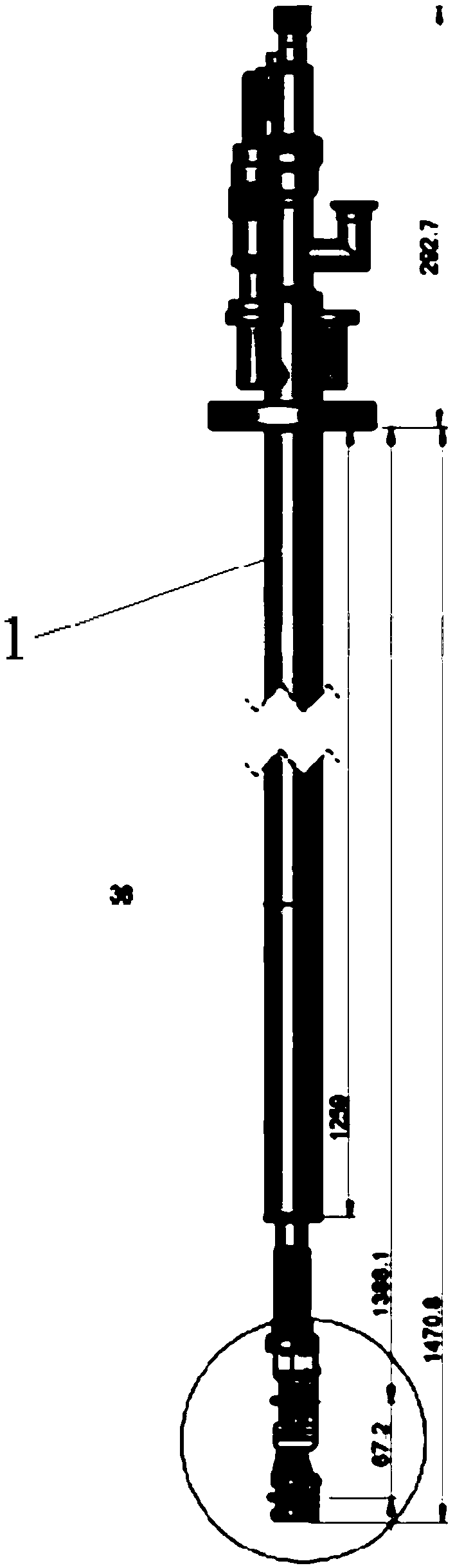

Vacuum interconnected surface analysis device and using method thereof

A surface analysis and vacuum technology, applied in the field of surface chemistry, can solve problems such as the inability to achieve interconnection and the incompatibility of sample holders, and achieve the effects of reducing background signal interference, facilitating imaging, and facilitating acquisition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

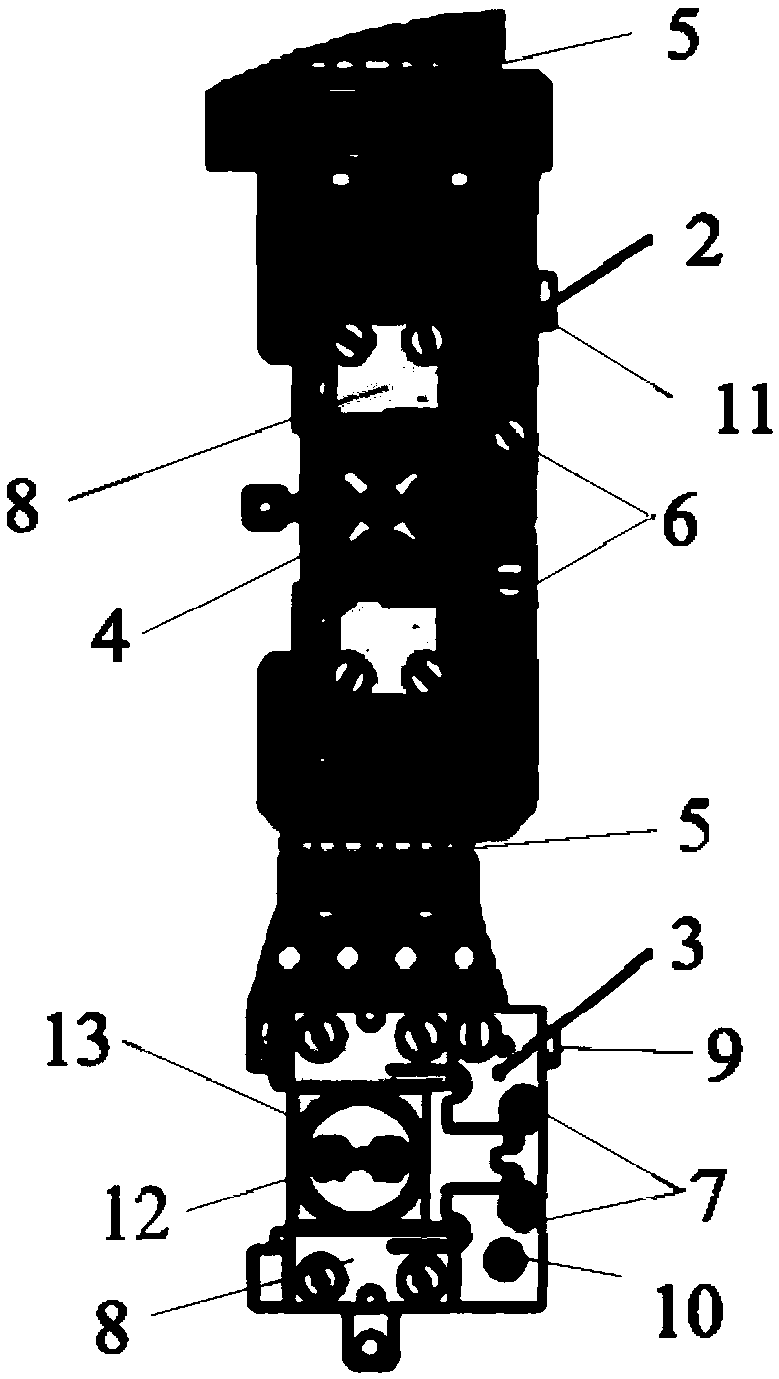

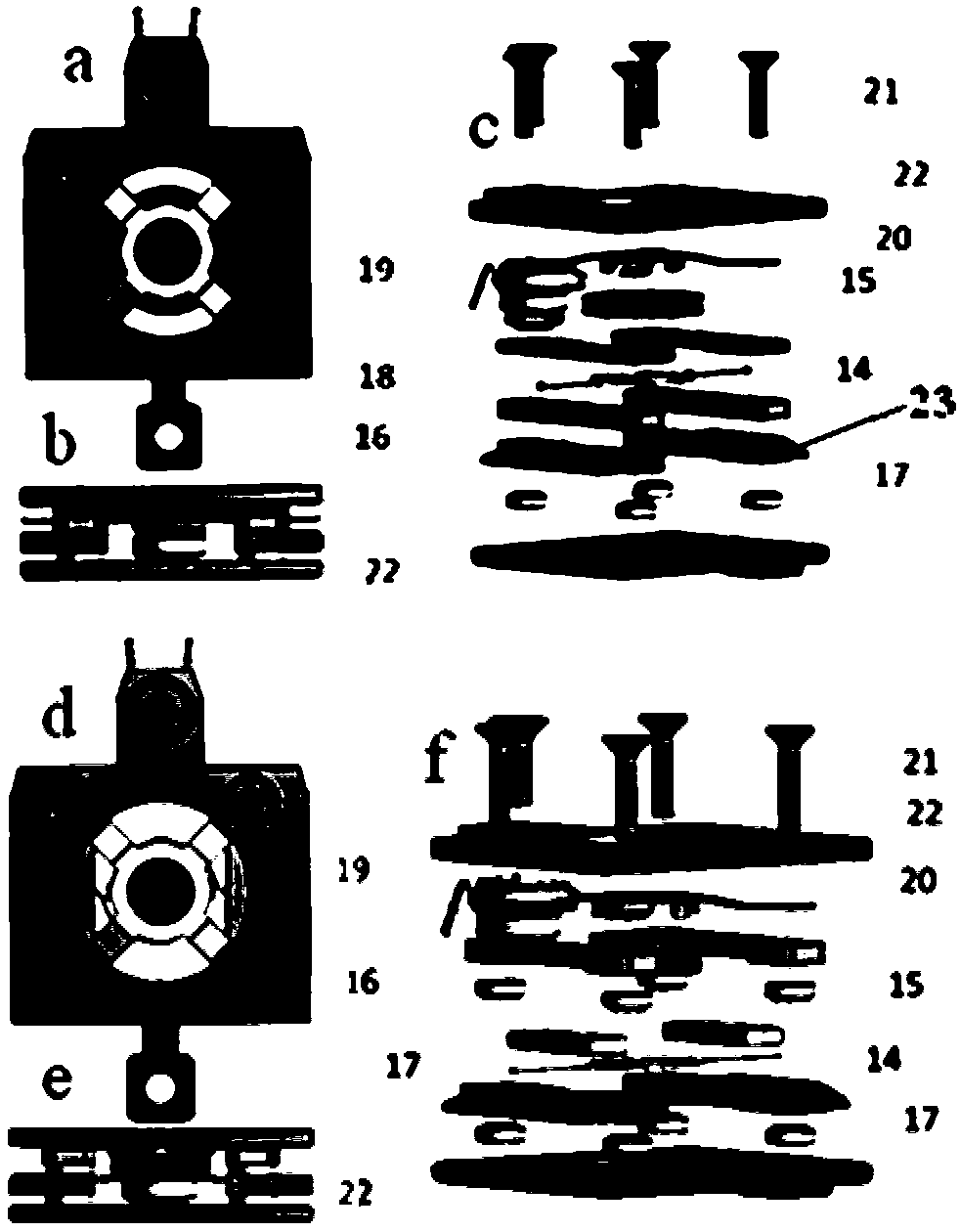

Method used

Image

Examples

Embodiment 1

[0071] This device can measure the desorption temperature of the lattice oxygen of FeO nano-islands on gold (Au), copper (Cu), platinum (Pt) metal substrates, infer the bond energy of the corresponding Fe-O bond, and study the metal substrate The regulation of bond energy here. This vacuum interconnected temperature programmed desorption device based on ultra-high vacuum conditions is connected with an ultra-high vacuum system.

[0072] Raise the temperature of the Fe evaporation source to a suitable temperature (~1300K) for degassing. The clean substrate sample Pt(111) prepared in the ultra-high vacuum system is directly transferred to the programmed temperature sample stage of the device through the propagating device. Gas valve into high-purity O 2 (99.999%) to 1×10-7mbar, open the baffle of the evaporation source, and deposit a FeO film to a suitable coverage. Then close the evaporation source damper and turn off the oxygen. After the chamber vacuum is restored, the obt...

Embodiment 2

[0074] This device can measure metastable FeO on gold (Au), copper (Cu), platinum (Pt) metal substrates 2 The desorption temperature of the lattice oxygen of the nano-island is used to deduce the bond energy of the corresponding Fe-O bond, and to study the regulation of the metal substrate on the metastable oxide bond energy here.

[0075] FeO / Pt(111) was prepared by the same preparation method as in Example 1. After the cavity vacuum is restored, the obtained thin film sample is fixed on the sample holder, and the sample holder is introduced into the scanning tunneling microscope chamber for structural analysis, and then 0.1mbar O 2 , imaged again to obtain FeO 2 / Pt(111). Then it is transferred to the temperature-programmed clamping plate for desorption experiment. Through the external software, the heating temperature is set to 3K / s, and the temperature is programmed. At the same time, the desorbed gas phase molecular peak with a mass number of 32 is collected, and the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com