Single-stage, multi-stage and variable-stage cyclone air flotation oily sewage treatment device

A swirling air flotation and treatment device technology, which is applied in the direction of flotation water/sewage treatment, multi-stage water treatment, water/sludge/sewage treatment, etc. Not suitable for problems such as offshore platforms, achieving convenient and stable circulation channels, avoiding repeated processing, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

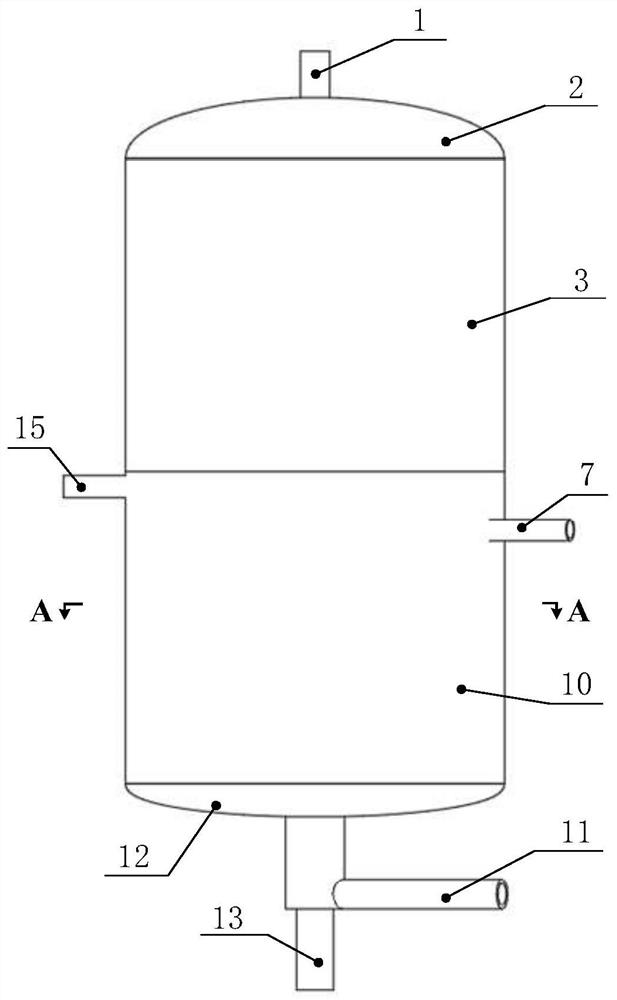

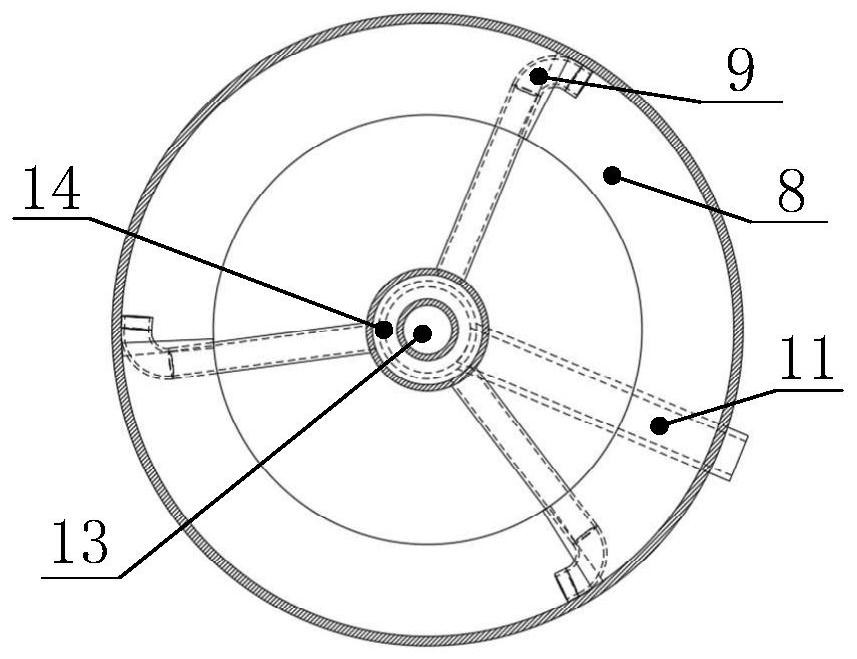

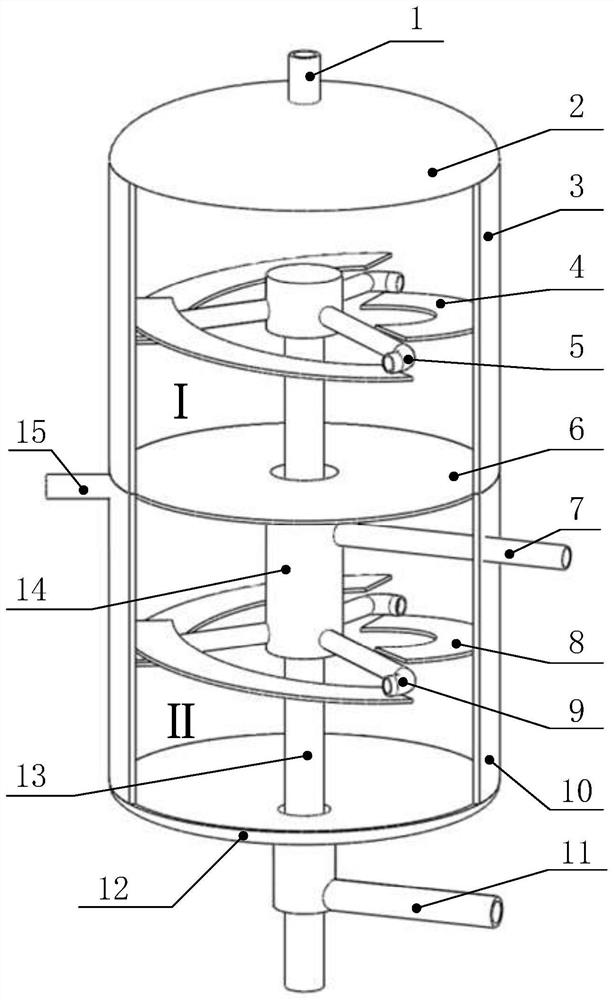

[0034] see figure 1 , figure 2 , image 3 , a two-stage cyclone air flotation oily sewage treatment device is characterized in that it includes an outer shell part composed of a first-stage cylindrical shell 3, a second-stage cylindrical shell 10, an upper seal head 2, and a lower seal head 12; it consists of a Level overflow pipe 1, secondary overflow pipe 15, secondary return pipe 7, underflow pipe 11, central standpipe 13 constitute the inlet and outlet pipeline part; Deflector 4, secondary deflector 8, secondary annular channel 14 and primary treated water collecting plate 6; wherein, the primary overflow pipe 1 is located at the top center of the upper head 2, and the secondary The primary overflow pipe 15 is located at the top position of the secondary cylinder body 10, and the secondary overflow pipe 15 is perpendicular to the central axis of the secondary cylinder body 10; the bottom flow pipe 11 is located on the lower head 12; the secondary return pipe 7 vertical...

Embodiment 2

[0043] see Figure 4 , a single-stage cyclone air flotation oily sewage treatment device, compared with the two-stage cyclone air flotation oily sewage treatment device in Example 1, it is equivalent to dismantling the primary treatment water collecting plate 6, the secondary return pipe 7, the secondary Level baffle 8, level 2 water distribution pipe 9, level 2 barrel 10, level 2 annular channel 14, level 2 overflow pipe 15.

[0044] The working process of the present invention is described as follows:

[0045] Uniformly mixed with gas to form oily sewage dissolved with microbubbles through the central standpipe 13, and tangentially flow out from the primary water distribution pipe 5 to form a swirling flow. It is advisable to control the centrifugal acceleration at the outlet of the water distribution pipe 5 at 15g~25g. Because the density of air bubbles and oil droplets is lower than that of water, they move centripetally and directionally in the swirl field, collide and c...

Embodiment 3

[0047] see Figure 5 , a three-stage cyclone air flotation oily sewage treatment device is on the basis of embodiment 1, adding a three-stage return pipe 16, a three-stage deflector 17, a three-stage water distribution pipe 18, a three-stage cylinder body 19, and a three-stage Annular channel 20 , tertiary overflow pipe 21 , and secondary treated water collecting plate 22 . The characteristics of the components in the third-level separation zone III are the same as those of the corresponding components in the secondary separation zone II.

[0048] The working process of the present invention is described as follows:

[0049] On the basis of Examples 1 and 2, the purified water after the secondary separation II flows to the secondary treated water collecting plate 22 below, and then flows to the tertiary separation through the tertiary annular channel 20 in the center of the secondary treated water collecting plate 22 Zone III. When the secondary purified water passes throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com