Millettia speciosa champ polysaccharide, preparation method and application thereof in antibacterial aspect

A technology of oxalicum and polysaccharide, which is applied in the field of natural active products, can solve the problems such as the lack of research reports on the separation, purification and activity evaluation of oxalicum polysaccharides, and achieves extensive development value and the effect of inhibiting growth and reproduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Embodiment 1: the preparation of bovine herbaceous polysaccharide MSCP1 and MSCP2

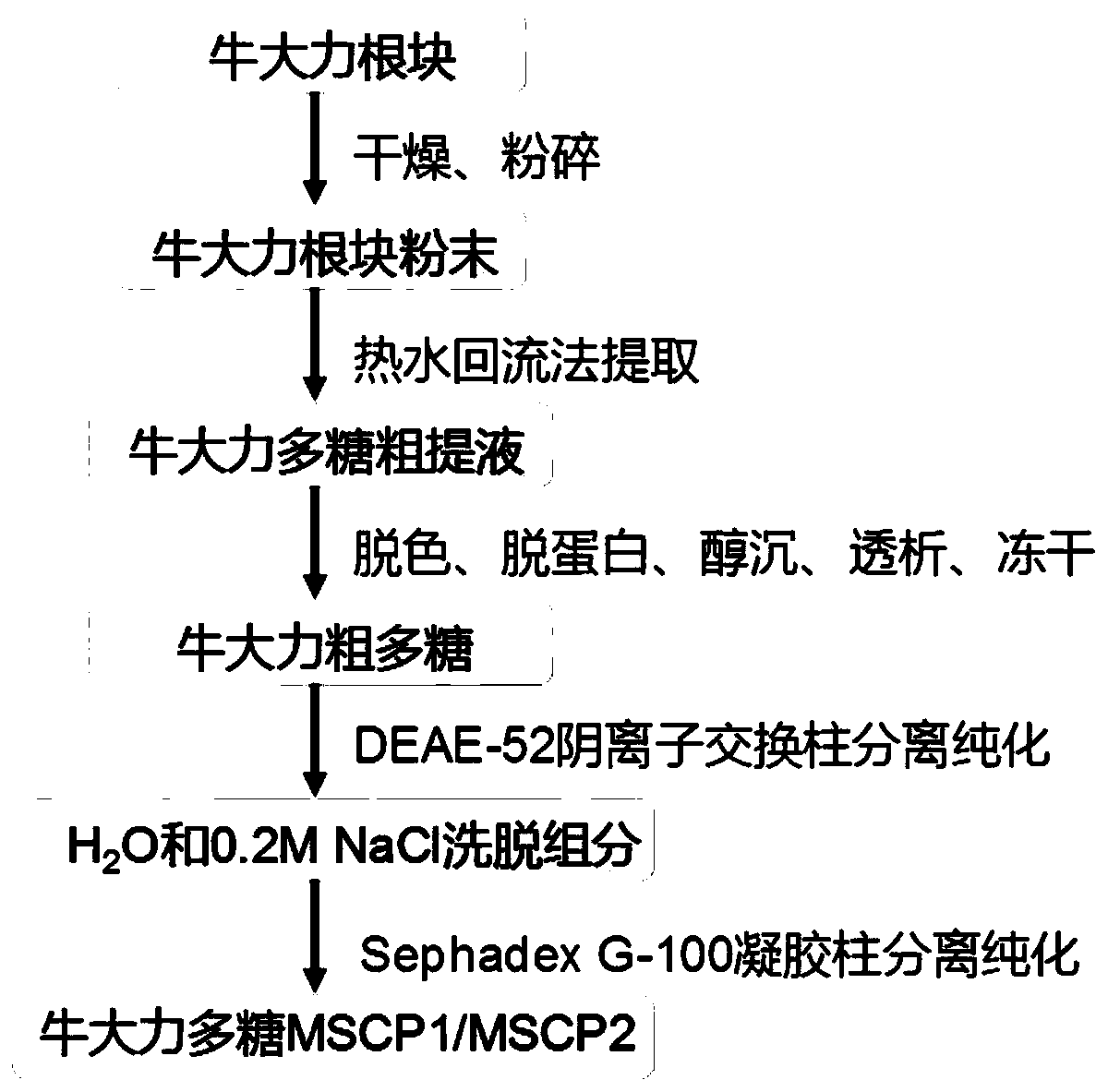

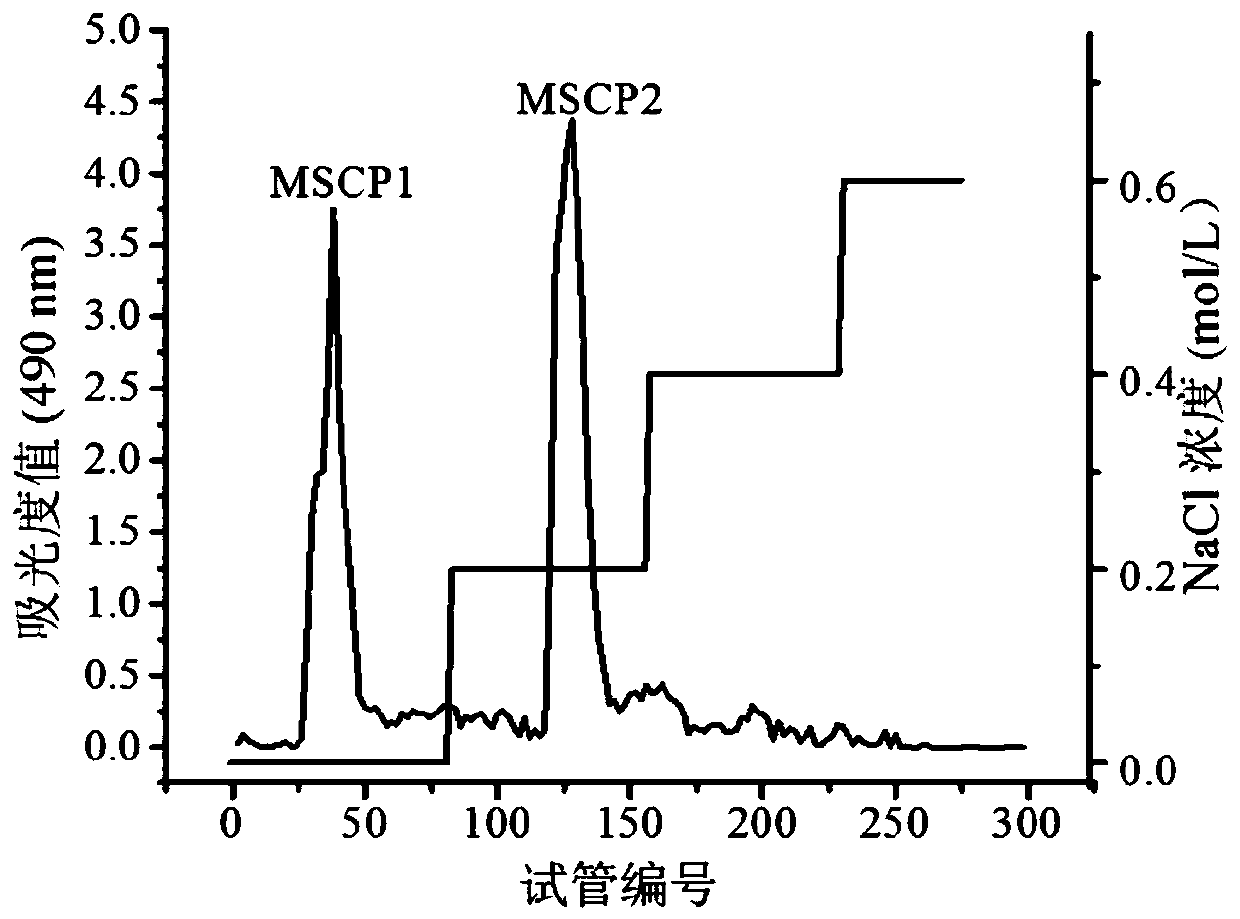

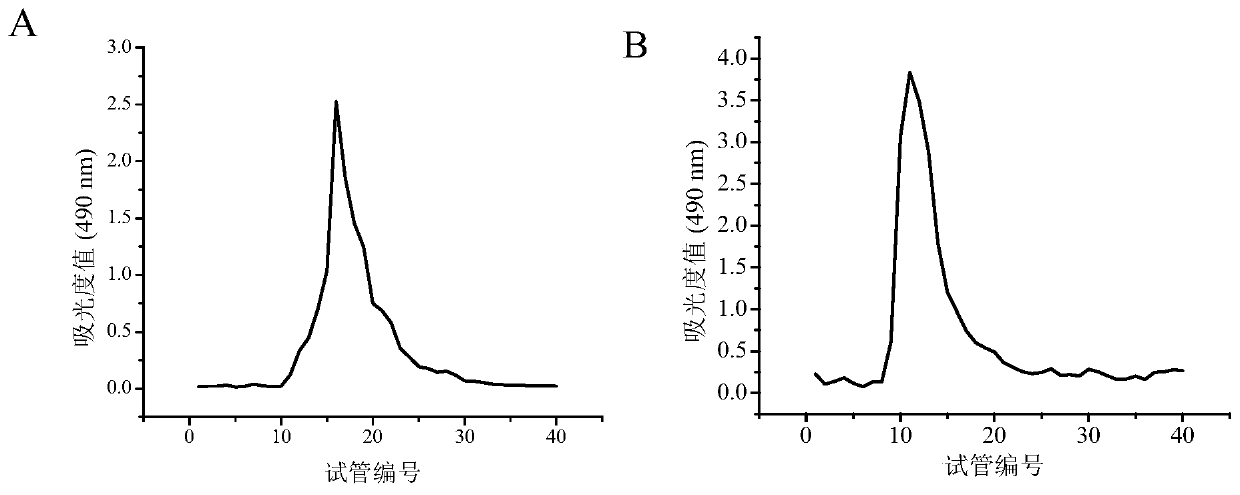

[0064] In the present invention, the separation and purification process of bovine vigorously polysaccharide is as follows: figure 1 Shown:

[0065] (1) Preparation of Niu Dali crude extract: Clean the root of Niu Dali (produced in Fengkai County, Zhaoqing City, Guangdong Province, China), cut into slices, dry (60°C for 15 hours), pulverize, pass through 100 Mesh sieve to obtain the root block powder of Niu Dali; use the hot water reflux method to extract the root block powder of Niu Dali, the conditions are temperature 80°C, material-liquid ratio 1:10, extraction time 1h; after the extraction, centrifuge to take the supernatant, Repeat the extraction twice according to the above conditions, combine the supernatants, concentrate under reduced pressure at 55°C to 1 / 4 of the volume, and obtain the crude extract of bovine herbaceous polysaccharide;

[0066] (2) Preparation of the crude po...

Embodiment 2

[0070] Embodiment 2: the preparation of bovine herbaceous polysaccharide MSCP1 and MSCP2

[0071] (1) Preparation of Niu Dali crude extract: Clean the root of Niu Dali (produced in Fengkai County, Zhaoqing City, Guangdong Province, China), cut into slices, dry (60°C for 15 hours), pulverize, pass through 100 Mesh sieve to obtain the root block powder of Niu Dali; use the hot water reflux method to extract the root block powder of Niu Dali, the conditions are temperature 90°C, material-liquid ratio 1:20, extraction time 2h; centrifuge after leaching to take the supernatant, Repeat the extraction twice according to the above conditions, combine the supernatants, concentrate under reduced pressure at 65°C to 1 / 4 of the volume, and obtain the crude extract of bovine herbaceous polysaccharide;

[0072] (2) Preparation of the crude polysaccharide of bovine vigorously: in order to remove the pigment and protein, add 300mL of crude polysaccharide of bovine vigorously to the AB-8 macro...

Embodiment 3

[0076] Embodiment 3: the preparation of bovine herbaceous polysaccharide MSCP1 and MSCP2

[0077] (1) Preparation of Niu Dali crude extract: Clean the root of Niu Dali (produced in Fengkai County, Zhaoqing City, Guangdong Province, China), cut into slices, dry (60°C for 15 hours), pulverize, pass through 100 Mesh sieve to obtain the root block powder of Niu Dali; use the hot water reflux method to extract the root block powder of Niu Dali, the conditions are temperature 100°C, material-liquid ratio 1:30, extraction time 3h; centrifuge after leaching to take the supernatant, Repeat the extraction twice according to the above conditions, combine the supernatants, concentrate under reduced pressure at 75°C to 1 / 4 of the volume, and obtain the crude extract of bovine herbaceous polysaccharide;

[0078] (2) Preparation of the crude polysaccharide of bovine vigorously: in order to remove the pigment and protein, add 300mL of crude polysaccharide of bovine vigorously to the AB-8 macr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com