High-elasticity wear-resistant polyurethane foaming shoe material and preparation method thereof

A thermoplastic polyurethane and polyurethane technology, applied in the field of foamed shoe materials, can solve the problems of lack of elasticity, wear resistance, poor portability, etc., achieve good dispersion and compatibility, uniform bubbles, and avoid weight loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

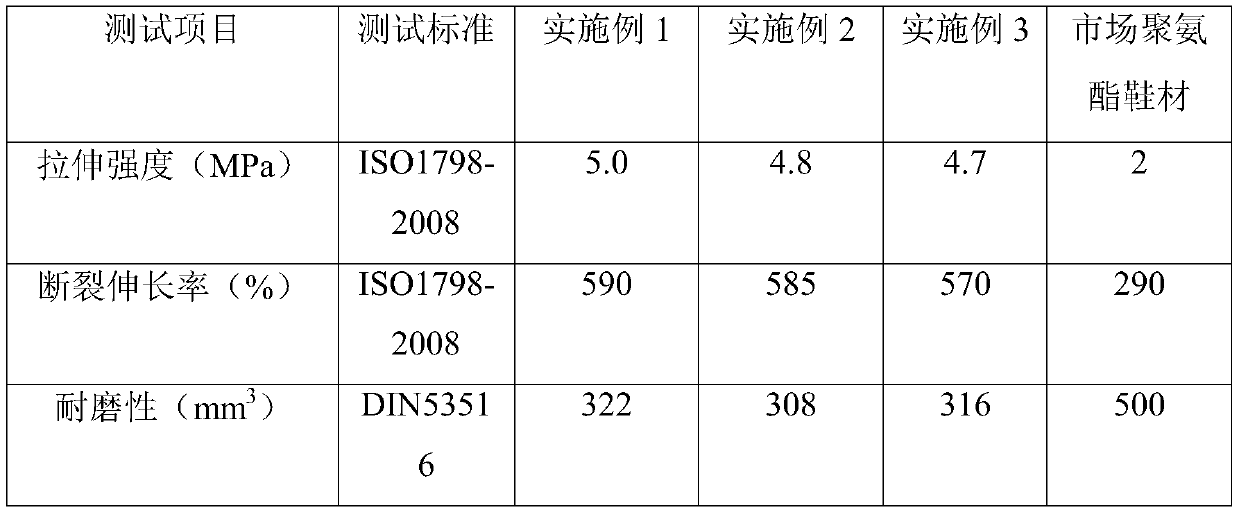

Examples

Embodiment 1

[0024] Embodiment 1: A kind of highly elastic wear-resistant polyurethane foam shoe material, comprises following components by weight: 70 parts of thermoplastic polyurethane elastomers, 10 parts of styrene-butadiene-styrene block copolymers, 15 parts of styrene-butadiene rubber 20 parts of ethylene-octene copolymer, 5 parts of blowing agent, 1 part of zinc oxide, 4 parts of crosslinking agent, 2 parts of co-crosslinking agent, 5 parts of active agent and 20 parts of filler.

[0025] Among them, the foaming agent is selected from azodicarbonamide, the active agent is selected from stearic acid, the filler is selected from hollow glass microspheres, the cross-linking agent is selected from dicumyl peroxide (DCP), and the auxiliary cross-linking agent is selected from triallylisocyanate. Cyanurate (TAIC).

[0026] A preparation method of highly elastic wear-resistant polyurethane foam shoe material, comprising the following steps:

[0027] (1) Weigh 70 parts of thermoplastic po...

Embodiment 2

[0030] Embodiment 2: a kind of highly elastic and wear-resistant polyurethane foam shoe material, comprising the following components by weight: 50 parts of thermoplastic polyurethane elastomers, 20 parts of styrene-butadiene-styrene block copolymers, 10 parts of styrene-butadiene rubber 10 parts of ethylene-octene copolymer, 1 part of foaming agent, 0.5 parts of zinc oxide, 2 parts of crosslinking agent, 1 part of co-crosslinking agent, 8 parts of active agent and 10 parts of filler.

[0031] Wherein, the thermoplastic polyurethane elastomer includes polymer polyol and isocyanate, which can be prepared by conventional methods in the art.

[0032] Among them, the foaming agent is N,N-dinitrosopentamethylenetetramine, the active agent is stearic acid, the filler is expanded perlite, and the crosslinking agent is 1,4-bis-tert-butylperoxyisopropyl Benzene (BIPB) and trimethylolpropane trimethacrylate (TMPTMA) were selected as co-crosslinking agent.

[0033] A preparation method ...

Embodiment 3

[0037] Embodiment 3: a kind of highly elastic and wear-resistant polyurethane foam shoe material comprises the following components by weight: 60 parts of thermoplastic polyurethane elastomers, 15 parts of styrene-butadiene-styrene block copolymers, 12 parts of styrene-butadiene rubber 15 parts of ethylene-octene copolymer, 3 parts of foaming agent, 0.8 parts of zinc oxide, 3 parts of crosslinking agent, 1.5 parts of co-crosslinking agent, 6 parts of active agent and 15 parts of filler.

[0038] Wherein, the thermoplastic polyurethane elastomer includes polymer polyol and isocyanate, which can be prepared by conventional methods in the art. For example, the polymer polyol is preferably polybutylene adipate diol, and the isocyanate is preferably 4,4'-diphenylmethane diisocyanate. The specific preparation method is as follows: by weight percentage, 40% poly Add butanediol adipate diol and 0.05% stannous octoate catalyst into A reactor equipped with mechanical stirring and thermo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com