High-strength soft water-permeable cotton and preparation process thereof, and cotton product

A preparation process and soft technology, applied in the field of permeable cotton and its preparation process and cotton products, can solve the problems of increased compression set, large compression set, and increased machine washing wrinkles, etc., to reduce the compression set , slow down the decline in mechanical properties, and improve the effect of strengthening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

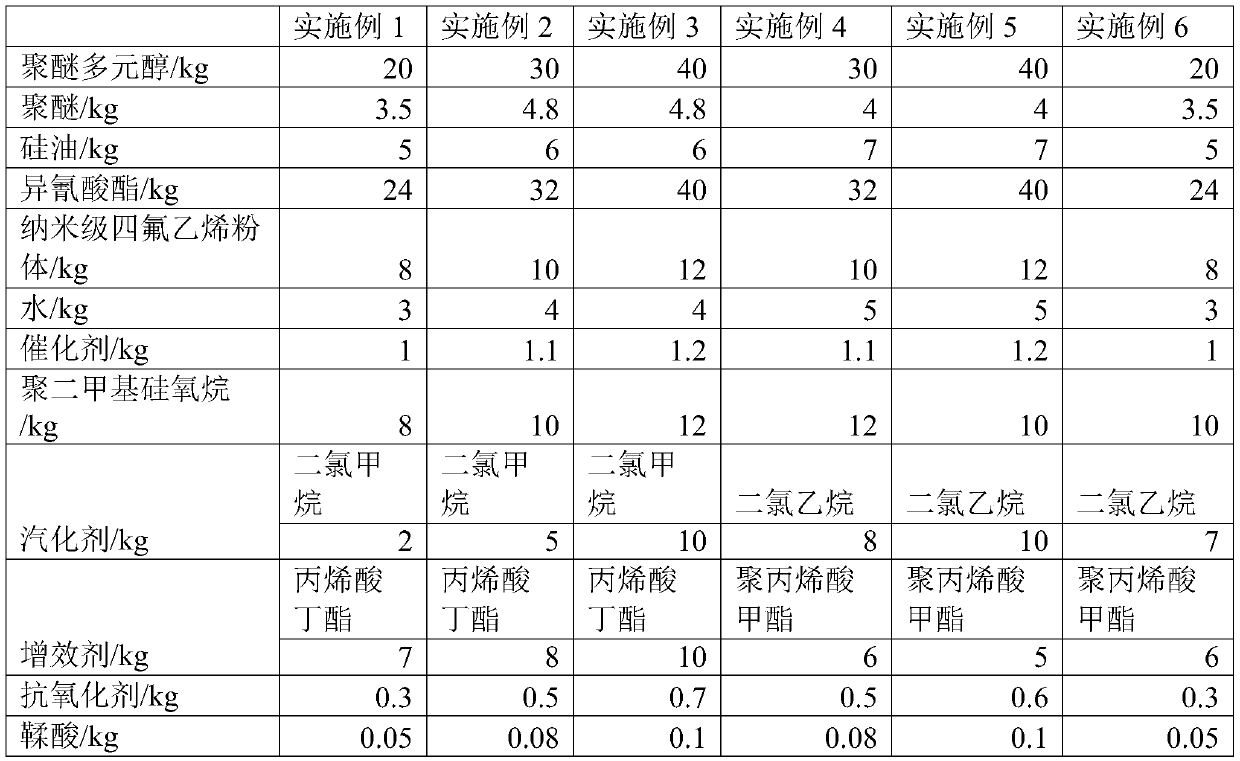

Embodiment 1

[0048] A high-strength and soft permeable cotton is obtained by mixing and foaming the following raw materials in parts by mass:

[0049] 20 parts of polyether polyol, 3.5 parts of polyether, 5 parts of silicone oil, 24 parts of isocyanate, 8 parts of nano-sized tetrafluoroethylene powder, 3 parts of water, 1 part of catalyst, 8 parts of polydimethylsiloxane, vaporizing agent 2 parts, 0.3 parts of antioxidant, 7 parts of synergist, 0.05 part of tannic acid.

[0050] The polyether polyol is selected here as polyether polyol N220.

[0051] The polyether is TPU American Lubrizol 2530.

[0052] Silicone oil is selected from finished product KB 8701 of Qingdao Kerun Biotechnology Co., Ltd.

[0053] The isocyanate is selected from Wanhua Chemical No. 8610 isocyanate.

[0054] The volume equivalent diameter of the nanoscale tetrafluoroethylene powder is 400nm.

[0055] The catalyst can be determined according to the actual situation, here is a composite catalyst, including trimethy...

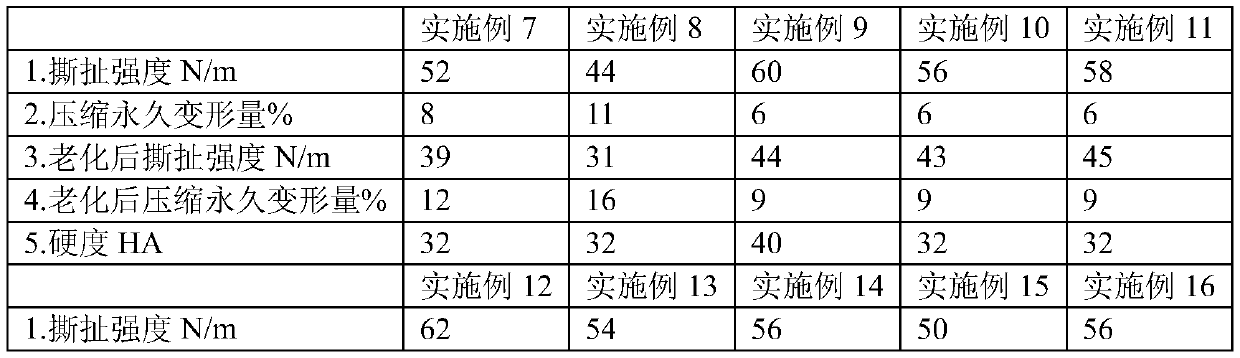

Embodiment 7

[0107] A kind of water-permeable cotton, which differs from Example 4 in that the amount of polymethyl acrylate is 5kg.

Embodiment 8

[0109] A kind of water-permeable cotton, which differs from Example 4 in that the amount of polymethyl acrylate is 2kg.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap