Preparation method of high-purity sponge palladium

A sponge palladium and high-purity technology is applied in the field of preparation of high-purity palladium sponge, which can solve the problems of long process flow and complicated steps, and achieve the effects of short process flow, simple steps and strong adaptability of raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

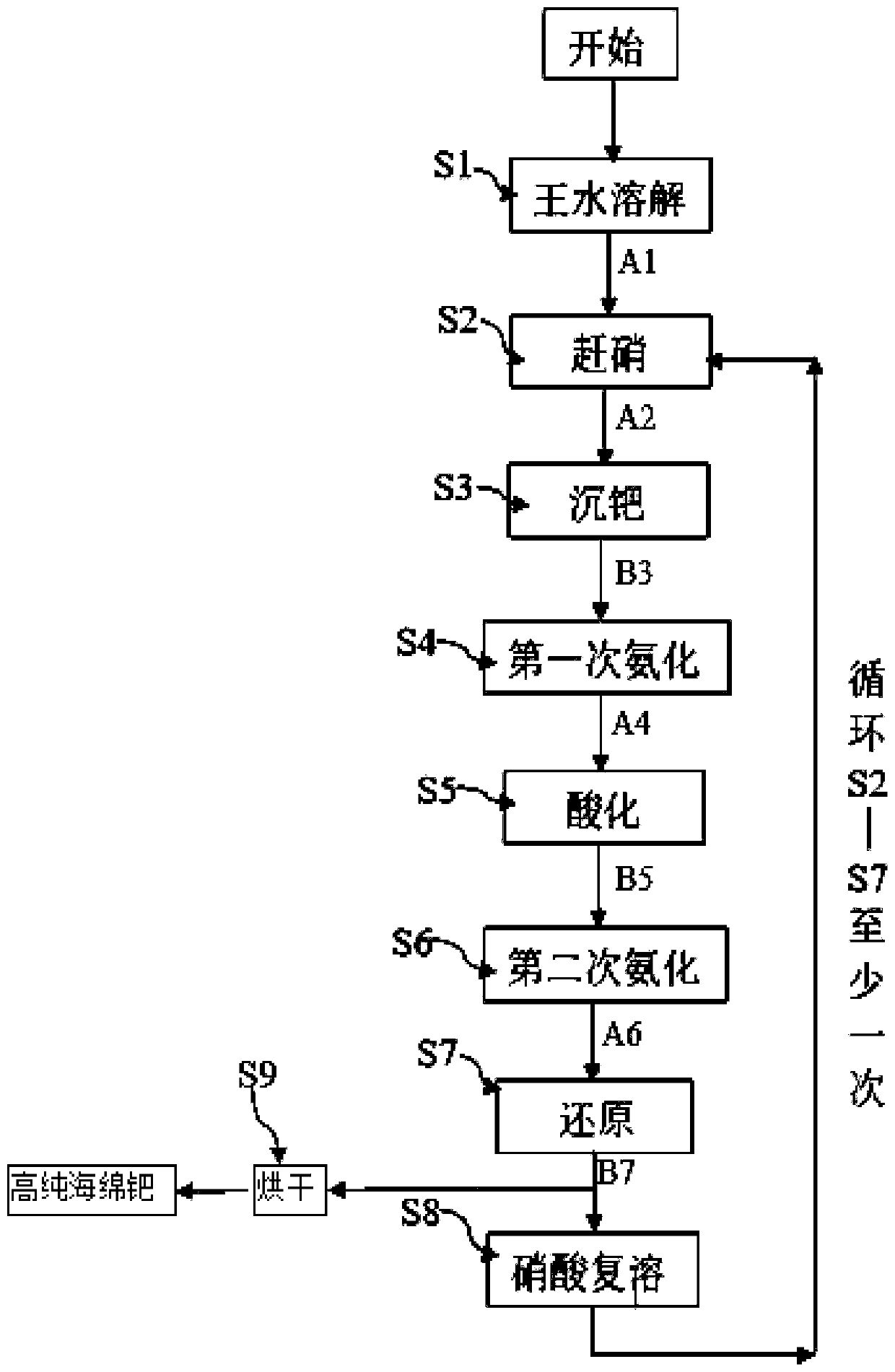

[0039] Such as figure 1 Shown, be the preparation method of high-purity palladium sponge of the present invention, it comprises steps:

[0040] S1: Dissolving in aqua regia: adding the crude palladium raw material into aqua regia, reacting at room temperature for 0.5-4h, dissolving the crude palladium raw material in aqua regia, filtering to obtain clear liquid A1 and solid slag B1;

[0041] S2: Nitrate removal: heat up the clear solution A1 to 40°C-100°C, add concentrated hydrochloric acid to remove the nitrate, and filter to obtain the clear liquid A2 and solid slag B2;

[0042] S3: Precipitating palladium: adding a precipitating agent and an oxidizing agent to the clear liquid A2, reacting at room temperature for 4-24 hours, and filtering to obtain clear liquid A3 and solid slag B3;

[0043] S4: The first ammonification: disperse the solid slag B3 into an appropriate amount of pure water, raise the temperature to 45°C-95°C and add ammonia water, ammoniate until the pH valu...

Embodiment 1

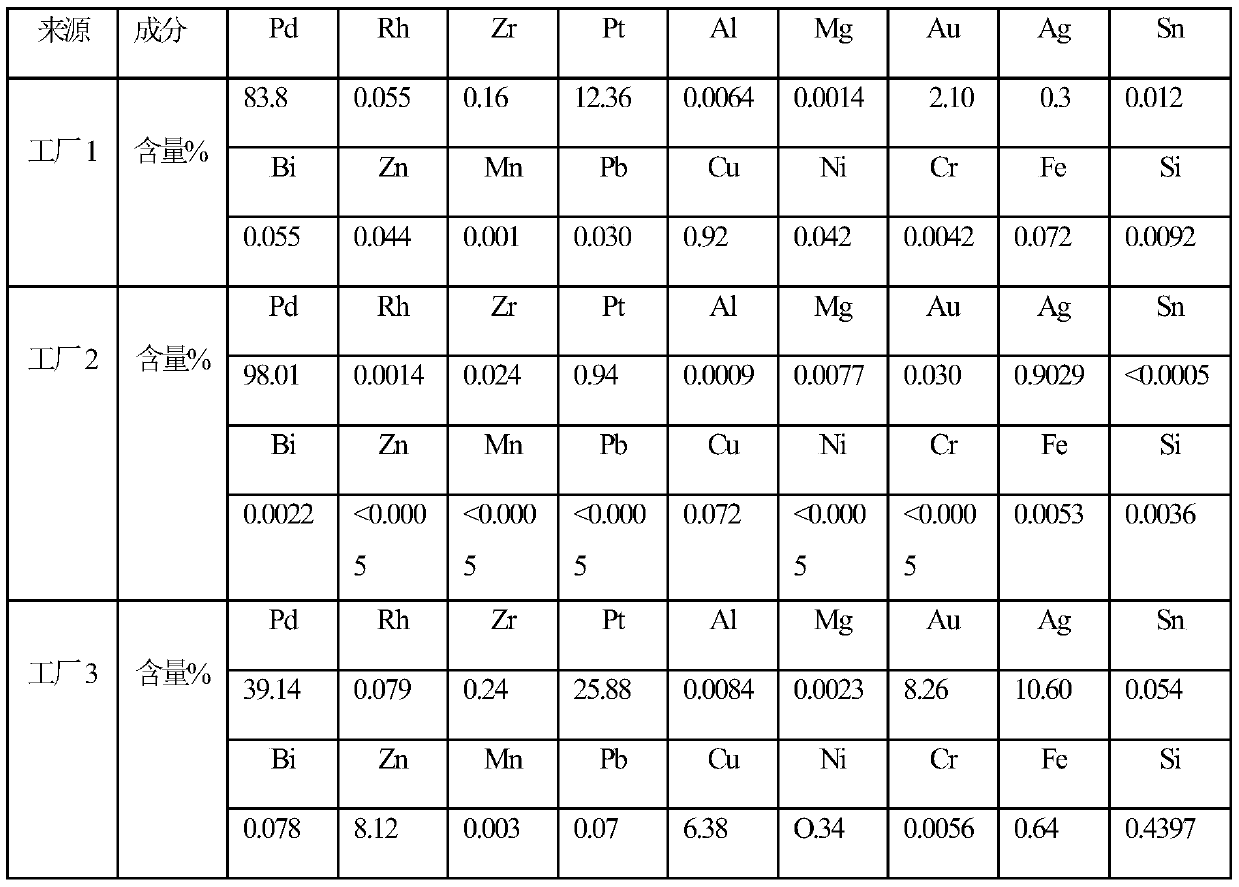

[0056] The present embodiment takes the crude palladium of the output of factory 1 as raw material (palladium content 83.7%), prepares high-purity sponge palladium, comprises steps:

[0057] ①The crude palladium is dissolved and filtered with aqua regia at room temperature;

[0058] ② Add concentrated hydrochloric acid to the filtrate at 80°C to catch the nitrate, and filter;

[0059] ③ Add precipitant and oxidant to the filtrate at room temperature, micro-oxidize and precipitate for 12 hours, and filter;

[0060] ④ Add water to the filter residue to make slurry, use ammonia water for the first ammoniation temperature of 65°C, keep warm for 2 hours until the pH value reaches 8-10, and filter;

[0061] ⑤ The filtrate is acidified with hydrochloric acid at room temperature to a pH value of 0.5-2, and filtered;

[0062] ⑥ Add water to the filter residue to adjust the slurry, use ammonia water for the second ammoniation, the ammoniation temperature is 65°C, keep warm for 2 hours...

Embodiment 2

[0067] The present embodiment takes the crude palladium of the output of factory 2 as raw material (palladium content 98.01%), prepares high-purity sponge palladium, comprises steps:

[0068] ①The crude palladium is dissolved and filtered with aqua regia at room temperature;

[0069] ②Add concentrated hydrochloric acid to the filtrate at 90°C to catch the nitrate, and filter;

[0070] ③ Precipitant and oxidant in the filtrate at normal temperature, micro-oxidized and precipitated for 8 hours, and filtered;

[0071] ④ Add water to the filter residue to adjust the slurry, use ammonia water for the first ammoniation temperature of 75°C, keep warm for 1h until the pH value reaches 8-10, and filter;

[0072] ⑤ The filtrate is acidified with hydrochloric acid at room temperature to a pH value of 0.5-2, and filtered;

[0073] ⑥ Add water to the filter residue to adjust the slurry, use ammonia water for the second ammoniation, the ammoniation temperature is 75°C, keep it warm for 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com