Electrolytic anode plate and preparation method thereof

A technology for anode plates and substrates, applied in electrodes, electrolysis processes, electroforming, etc., can solve the problems of easy deactivation and corrosion of active materials, uneven distribution of active materials, short service life, etc., and achieve increased preparation costs and uniform distribution of activity , the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

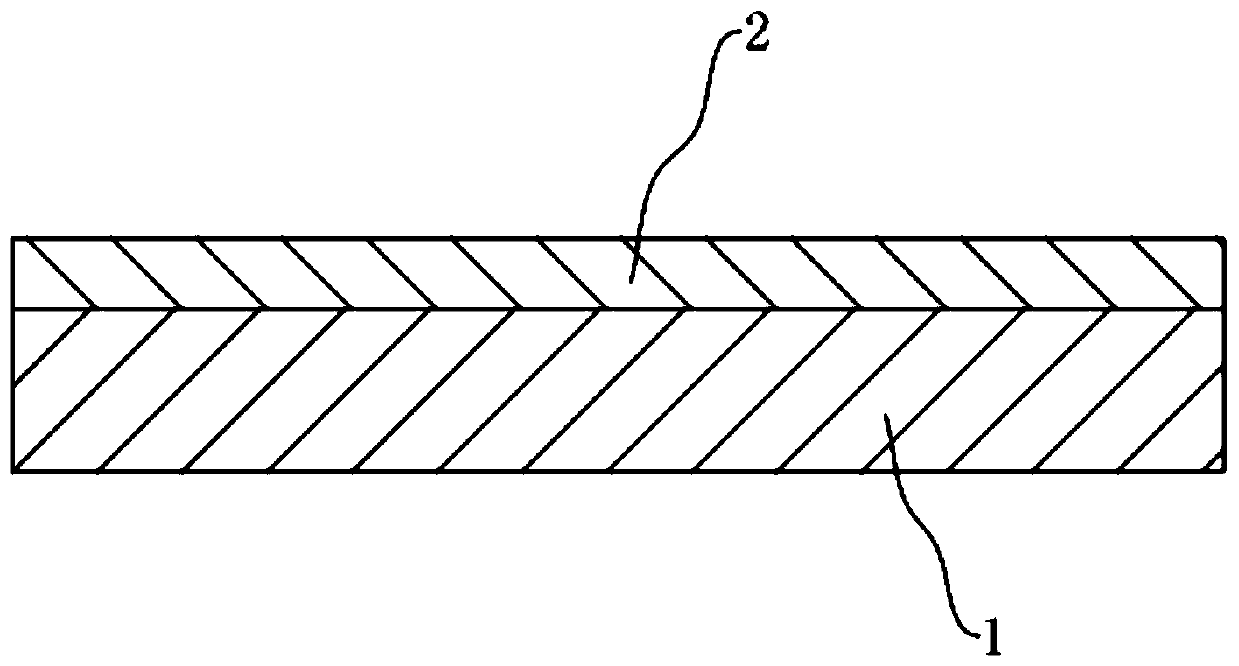

[0033] Embodiment 1: A method for preparing an electrolytic anode plate, which can improve the service life of the anode plate, such as figure 1 shown, including the following steps:

[0034] S1. Select a titanium plate as the substrate, and cut and process it into a substrate 1 according to requirements;

[0035] S2. Take a compound containing iridium as element 1, take a compound containing tantalum, a compound containing ruthenium or a compound containing tantalum mixed with a compound containing ruthenium as element 2, mix element 1 and element 2 uniformly and make a coating The target material; specifically, iridium oxide is selected for the compound containing iridium, tantalum oxide is selected for the compound containing tantalum, and ruthenium oxide is used for the compound containing ruthenium, and the coating target is made of powdery solid material, wherein, element one and element The weight ratio between the two is 1:1 to 1.5. In this embodiment, the element two...

Embodiment 2

[0042]Embodiment 2: The difference between this embodiment and Embodiment 1 is that in step S4, the pre-sputtering is maintained for 3.5 minutes when the sputtering power value of the main sputtering is reached, so that the sputtering environment in the reaction chamber is stable, so that the main sputtering is carried out. Sputtering, and control the main sputtering at 60min, so as to obtain the iridium-tantalum coating 2 with a thickness of 1.8 μm, avoiding the waste caused by the over-thickness of the coating 2, increasing the cost of electrode preparation, and avoiding the residual stress of the coating 2. The binding force between the coating 2 and the substrate 1 is reduced to ensure a relatively high service life of the electrolytic anode plate. In the prepared coating 2, the sputtering amount of iridium oxide is 12g / m2, so as to maximize the electrode capacity of the coating 2, improve the electrode performance of the coating 2, and thereby increase the service life of ...

Embodiment 3

[0043] Embodiment three: the difference between this embodiment and embodiment one is that when magnetron sputtering is carried out in step S4, the sputtering amount of iridium oxide and tantalum oxide on the substrate 1 is 10g / m2, and the temperature of the control substrate 1 is at 480°C, so that the activity of iridium-tantalum is stable during sputtering, and the formed iridium-tantalum coating 2 has higher activity and longer life.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com