A kind of electrolyte and its application in electrochemical energy storage device

An electrolyte and electrolyte technology, applied in the field of electrochemical energy storage, can solve the problems of high production cost, flammability of organic solvents, poor safety, etc., achieve high voltage window, wide working temperature range, improve electrochemical performance and application range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The specific composition of the mixed electrolyte of this example is solvent (water and acetonitrile), the functional solute of confined water molecules is sucrose, and the electrolyte is sodium nitrate. Put 1g of deionized water and 0.3g of acetonitrile in a glass sample bottle, seal it, put it in a blast drying oven at 90°C and heat it for 20 minutes until fully dissolved, and then obtain the mixed electrolyte of this example after cooling. Among them, the mass fraction of sucrose in the electrolyte is 51.7%. The electrochemical window test of the mixed electrolyte prepared in this example was carried out by linear voltammetry (saturated calomel electrode as reference electrode, platinum disk electrode as working electrode, and platinum sheet electrode as counter electrode). The results show that the electrochemical stability window of the mixed electrolyte is 2.5V.

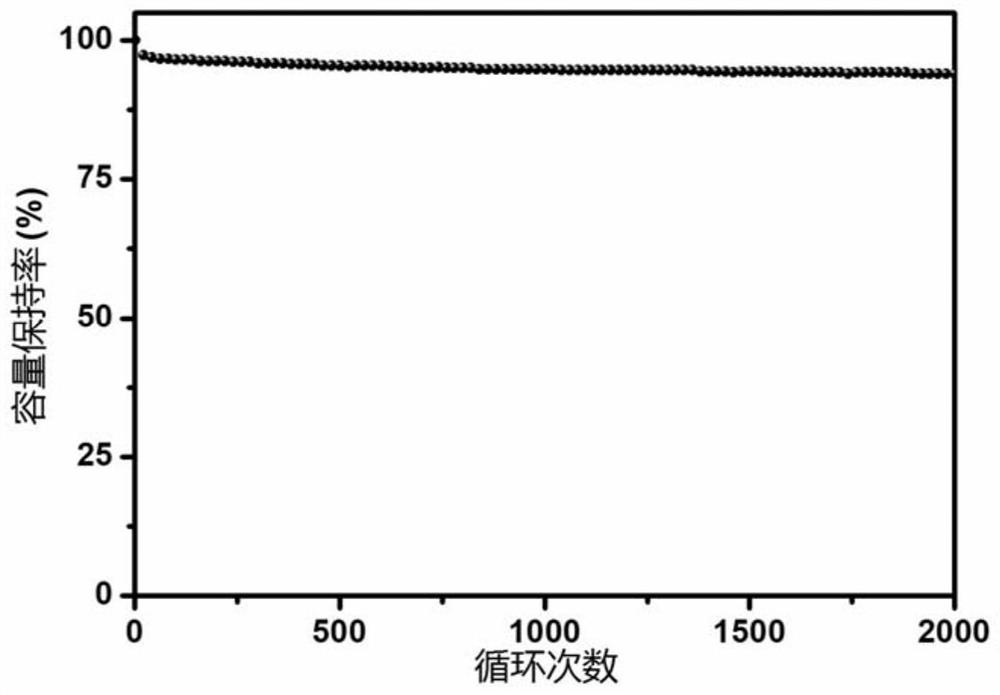

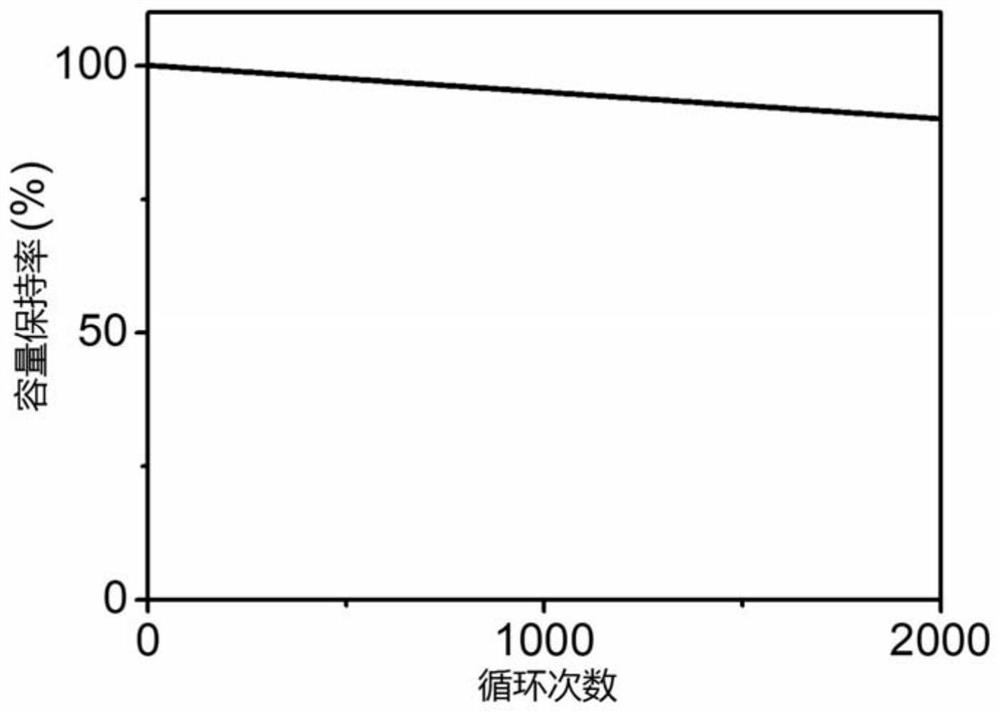

[0034] The mixed electrolyte solution of this example is used in the assembly of aqueous sodium ion ...

Embodiment 2

[0036] The specific composition of the mixed electrolyte of this example is solvent (water and acetonitrile), the functional solute of confined water molecules is maltose, and the electrolyte is sodium nitrate. The preparation method is as follows: Weigh 1g of maltose and 0.1g of sodium nitrate into Put deionized water and 0.3g of acetonitrile in a glass sample bottle, seal it, put it in a blast drying oven at 90°C and heat it for 20 minutes until it is fully dissolved. After cooling, the mixed electrolyte of this example is obtained. Among them, the mass fraction of maltose in the electrolyte is 41.7%. The electrochemical window test of the mixed electrolyte prepared in this example was carried out by linear voltammetry (saturated calomel electrode as reference electrode, platinum disk electrode as working electrode, and platinum sheet electrode as counter electrode). The results show that the electrochemical stability window of the mixed electrolyte is 2.4V.

[0037] The mi...

Embodiment 3

[0039] The specific composition of the mixed electrolyte of this example is a solvent (water and acetonitrile), the functional solute of confined water molecules is fructose, and the electrolyte is sodium nitrate. Put 1g of deionized water and 0.3g of acetonitrile in a glass sample bottle, seal it, put it in a blast drying oven at 90°C and heat it for 20 minutes until fully dissolved, and then obtain the mixed electrolyte of this example after cooling. Among them, the mass fraction of fructose in the electrolyte is 51.7%. The electrochemical window test of the mixed electrolyte prepared in this example was carried out by linear voltammetry (saturated calomel electrode as reference electrode, platinum disk electrode as working electrode, and platinum sheet electrode as counter electrode). The results show that the electrochemical stability window of the mixed electrolyte is 2.3V.

[0040] The mixed electrolyte solution of this example is used in the assembly of aqueous sodium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com