Low voltage, high capacity self-supporting potassium ion battery negative electrode and its preparation and application

A battery negative, low voltage technology, applied in battery electrodes, negative electrodes, secondary batteries, etc., can solve the problems of pollutant generation, high charging platform, and difficulty in meeting battery production standards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Pretreatment of self-supporting structural carbon materials: the 10×10cm 2 The commercialized carbon fiber fabrics were ultrasonically cleaned for 10 minutes by immersion in absolute ethanol, chloroform, and toluene, and then dried in an oven after being taken out.

[0035] (2) Concentrated sulfuric acid: concentrated perchloric acid = 0.2:1 to prepare a mixed strong acid, add the above-cleaned and dried commercial carbon fiber fabric to the mixed strong acid, and place it under magnetic stirring and constant temperature heating at 70°C for 36 hours.

[0036] (3) The carbon fiber fabric after the above treatment was placed in a muffle furnace and annealed at 400° C. for 1 hour, and the acidified carbon fiber fabric was obtained after cooling down.

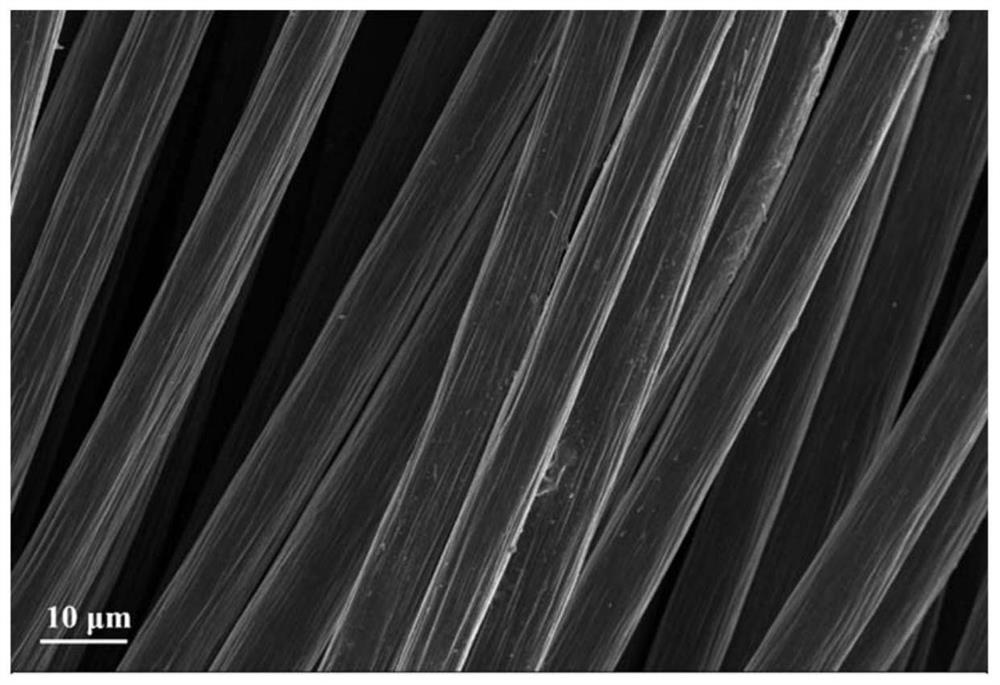

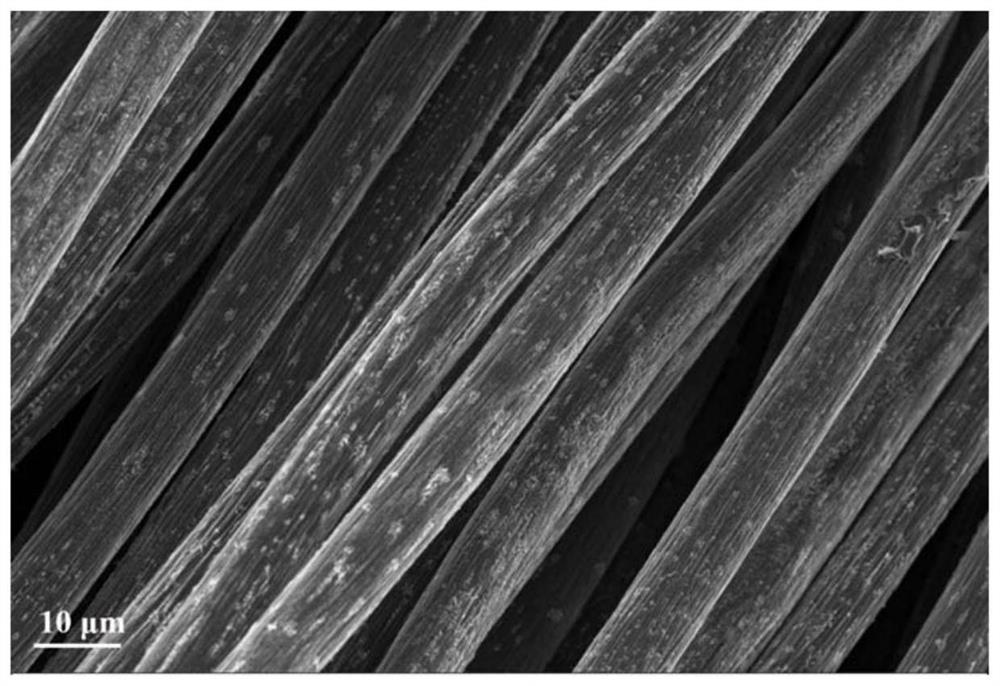

[0037] Figure 1-2 They are the scanning electron micrographs of the commercialized carbon fiber fabrics before and after the acidification treatment in Example 1, respectively. It can be seen from the figure that the ...

Embodiment 2

[0041] (1) Pretreatment of self-supporting structural carbon materials: Mix 0.1g carbon nanotubes, 0.1g lecithin and 200ml deionized water, form carbon nanotube ink after ultrasonic vibration for 15min, and vacuum filter the above ink into 3× 3cm 2 film and dried in an oven.

[0042] (2) Concentrated nitric acid by volume: concentrated hydroiodic acid = 2:1 to prepare a mixed strong acid, add the above cleaned and dried carbon nanotube film to the mixed strong acid, and place it under magnetic stirring and constant temperature heating at 90°C Heating in medium for 48h.

[0043] (3) The carbon nanotube film after the above treatment was placed in a tube furnace, heated to 600° C. under a nitrogen protection atmosphere with a flow rate of 100 ssm and kept for 2 hours, and the acidified carbon nanotube film was obtained after cooling down.

[0044] Figure 5-6They are scanning electron micrographs of the commercialized carbon nanotube films before and after the acidification t...

Embodiment 3

[0048] (1) Pretreatment of self-supporting structural carbon materials: the 5 × 5cm 2 The commercial graphite paper was soaked in 80% ethanol aqueous solution and ultrasonically cleaned for 10 min.

[0049] (2) Concentrated sulfuric acid by volume: concentrated nitric acid = 1:1 to prepare a mixed strong acid, add the mixed strong acid to the above-mentioned cleaned and dried commercial carbon fiber fabric, and place it under magnetic stirring and heating at a constant temperature of 85°C for heating 24h.

[0050] (3) The commercialized graphite paper treated above was placed in a muffle furnace and annealed at 450° C. for 1 h, and the acidified graphite paper was obtained after cooling down.

[0051] Figure 9-10 They are scanning electron micrographs of the commercialized carbon nanotube films before and after the acidification treatment in Example 3, respectively. It can be seen from the figure that the acidification treatment increases the wrinkles on the electrode surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com