Preparation method of UiO-66 loaded tin sulfide nanoparticle photocatalyst

A nanoparticle and photocatalyst technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, organic compounds/hydrides/coordination complex catalysts, etc., can solve problems such as limiting practical applications, and achieve improved photocatalytic activity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

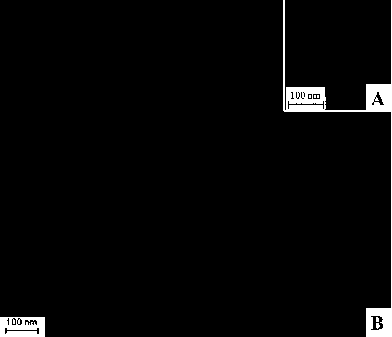

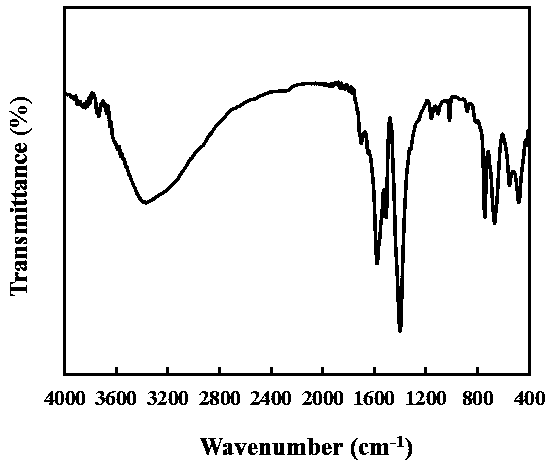

[0043] Example 1 Preparation method of UiO-66 loaded tin sulfide nanoparticle photocatalyst:

[0044] Firstly, using zirconium salt and organic ligand as precursor and polar solvent as dispersant, the octahedral UiO-66 white solid powder was prepared by solvothermal method. The specific process is as follows:

[0045] (1) Add 0.5000 g ZrCl 4 and 0.2507 g of terephthalic acid were dissolved in 50 mL of N,N'-dimethylformamide and stirred for 35 min, then 2.5 mL of acetic acid was added dropwise to the solution to adjust the morphology of UiO-66, and after stirring for 70 min , to obtain a homogeneous solution;

[0046] (2) The homogeneous solution was heated at 110°C for 24 hours, cooled to room temperature, and centrifuged at 7500 rpm for 5 minutes to obtain a white product;

[0047] (3) The white product was washed with distilled water and absolute ethanol three times in turn, and then vacuum-dried at 60°C to constant weight to obtain the obtained product.

[0048] Then, u...

Embodiment 2

[0051] Example 2 Preparation method of UiO-66 loaded tin sulfide nanoparticle photocatalyst:

[0052] Firstly, using zirconium salt and organic ligand as precursor and polar solvent as dispersant, the regular octahedral UiO-66 white solid powder was prepared by solvothermal method. The specific process is as follows:

[0053] (1) Add 0.2009 g ZrOCl 2 ·8H 2 O and 0.2016 g of 2-aminoterephthalic acid were dissolved in 60 mL of distilled water and stirred for 15 min, then 12.0 mL of acetic acid was added dropwise to the solution to adjust the form of UiO-66, and after continuing to stir for 100 min, a homogeneous solution was obtained;

[0054](2) The homogeneous solution was heated at 120°C for 36 hours, cooled to room temperature, and centrifuged at 8500 rpm for 10 minutes to obtain a white product;

[0055] (3) The white product was washed twice with distilled water and absolute ethanol in turn, and then vacuum-dried at 60°C to constant weight to obtain the obtained product...

Embodiment 3

[0059] Example 3 Preparation method of UiO-66 loaded tin sulfide nanoparticle photocatalyst:

[0060] Firstly, using zirconium salt and organic ligand as precursor and polar solvent as dispersant, the octahedral UiO-66 white solid powder was prepared by solvothermal method. The specific process is as follows:

[0061] (1) Add 0.0778 g Zr(NO 3 ) 4 ·5H 2 O and 0.1556 g of 2-aminoterephthalic acid were dissolved in a mixture of 35 mL of N,N'-dimethylformamide and distilled water and stirred for 60 min, then 12.3 mL of acetic acid was added dropwise to the solution to adjust UiO- 66, after stirring for 30 minutes, a uniform solution was obtained; the mixture of N,N'-dimethylformamide and distilled water refers to the volume of N,N'-dimethylformamide and distilled water at 1:0.8 Ratio (mL / mL) mixed uniformly obtained mixture;

[0062] (2) The homogeneous solution was heated at 100°C for 18 hours, cooled to room temperature, and centrifuged at 7500 rpm for 5 minutes to obtain a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com