High-thermal-conductivity boron nitride/epoxy resin composite material and preparation method and application thereof

A technology of epoxy resin and composite materials, which is applied in the field of electronic packaging materials, can solve the problem of low resistivity of composite materials, achieve the effects of improving interface matching and bonding strength, improving thermal conductivity, and improving thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

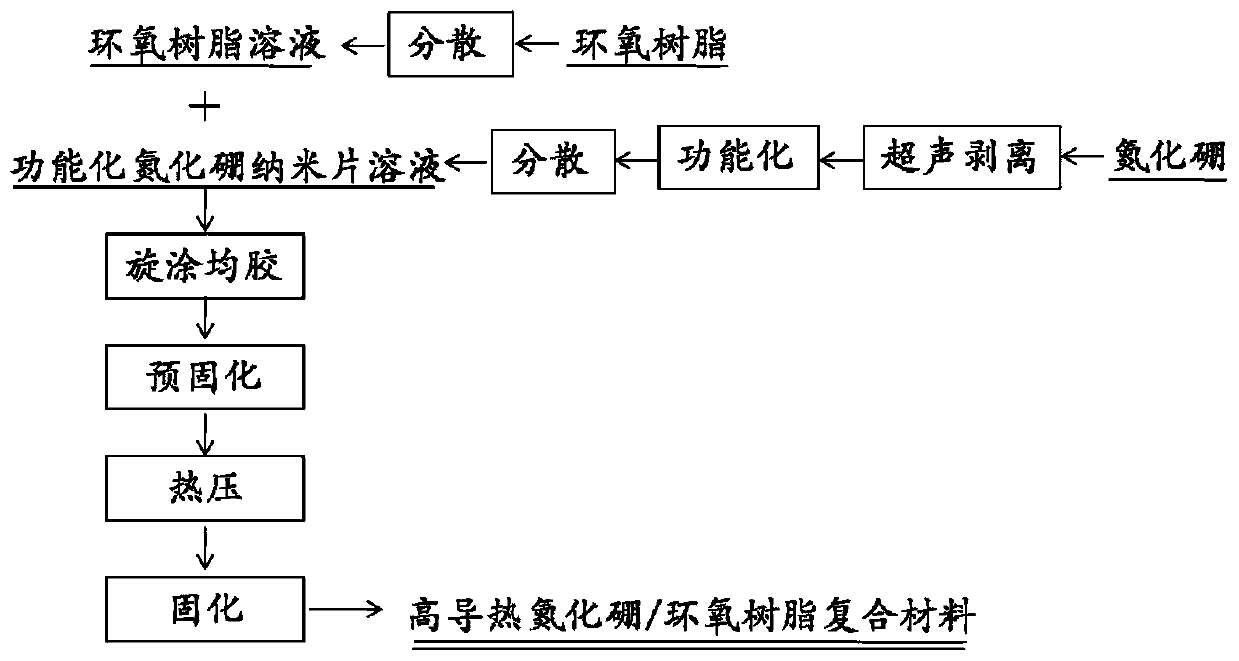

Method used

Image

Examples

Embodiment 1

[0035] Step 1: Weigh 3g of the original boron nitride powder and add it to 600mL of a mixed solution of isopropanol and deionized water (volume ratio is 1:1), and perform peeling by ultrasonication in a water bath for 12 hours;

[0036] Step 2: Centrifuge the ultrasonically treated upper layer dispersion at a speed of 2000 rpm for 20 minutes to remove residual unstripped boron nitride, then vacuum filter the upper layer centrifugal liquid, and dry it at 100°C for 10 hours to obtain boron nitride Nanosheets;

[0037] Step 3: adding a silane coupling agent with a mass of 9% (0.18 g) of boron nitride nanosheets to 300 mL of ethanol aqueous solution, and magnetically stirring the mixed solution at 60° C. for 30 min to hydrolyze the silane coupling agent;

[0038] Step 4: Add 2 g of boron nitride nanosheet powder to the solution in step 3, and perform magnetic stirring at 70° C. for 10 h again to functionalize the boron nitride nanosheets;

[0039] Step 5: Filter the dispersion li...

Embodiment 2

[0047] Step 1: Weigh 3g of original boron nitride powder and add it to a mixed solution of 600ml of isopropanol and deionized water (volume ratio is 1:1), and perform peeling by ultrasonication in a water bath for 12 hours; the particle size of the original boron nitride powder is 1 ~2μm; ultrasonic power is 180W, ultrasonic time is 12h;

[0048] Step 2: Centrifuge the ultrasonically treated upper layer dispersion at a speed of 2000 rpm for 20 minutes to remove residual unstripped boron nitride, then vacuum filter the upper layer centrifugal liquid, and dry it at 100°C for 10 hours to obtain boron nitride Nanosheets; the planar size of the obtained boron nitride nanosheets is 50-500nm, and the average size of 100 samples is about 301nm; the thickness is 2-3nm;

[0049] Step 3: adding a silane coupling agent with a mass of 3% (0.06g) of boron nitride nanosheets to 100ml of ethanol aqueous solution, and magnetically stirring the mixed solution at 60° C. for 30 minutes to hydroly...

Embodiment 3

[0062] Step 1: Weigh 3g of original boron nitride powder and add it to 600ml of a mixed solution of isopropanol and deionized water (volume ratio is 1:1), and perform peeling by ultrasonication in a water bath for 12 hours;

[0063] Step 2: Centrifuge the ultrasonically treated upper layer dispersion at a speed of 2000 rpm for 20 minutes to remove residual unstripped boron nitride, then vacuum filter the upper layer centrifugal liquid, and dry it at 100°C for 10 hours to obtain boron nitride Nanosheets;

[0064] Step 3: adding 0.05% (0.001g) silane coupling agent of boron nitride nanosheets into 20 ml of ethanol aqueous solution, and stirring the mixed solution magnetically at 60° C. for 30 min to hydrolyze the silane coupling agent;

[0065] Step 4: Add 2 g of boron nitride nanosheet powder to the solution in step 3, and then perform magnetic stirring at 90° C. for 5 hours to functionalize the boron nitride nanosheets;

[0066] Step 5: Filter the dispersion obtained in Step ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com