Coal gasification system and method for treating organic waste liquid

A technology of organic waste liquid and gasification system, which is applied in the field of coal gasification, can solve the problems of high processing difficulty, high processing cost, and difficult processing, and achieve good back-mixing effect, simplified process, and uniform distribution of flow field and temperature field Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

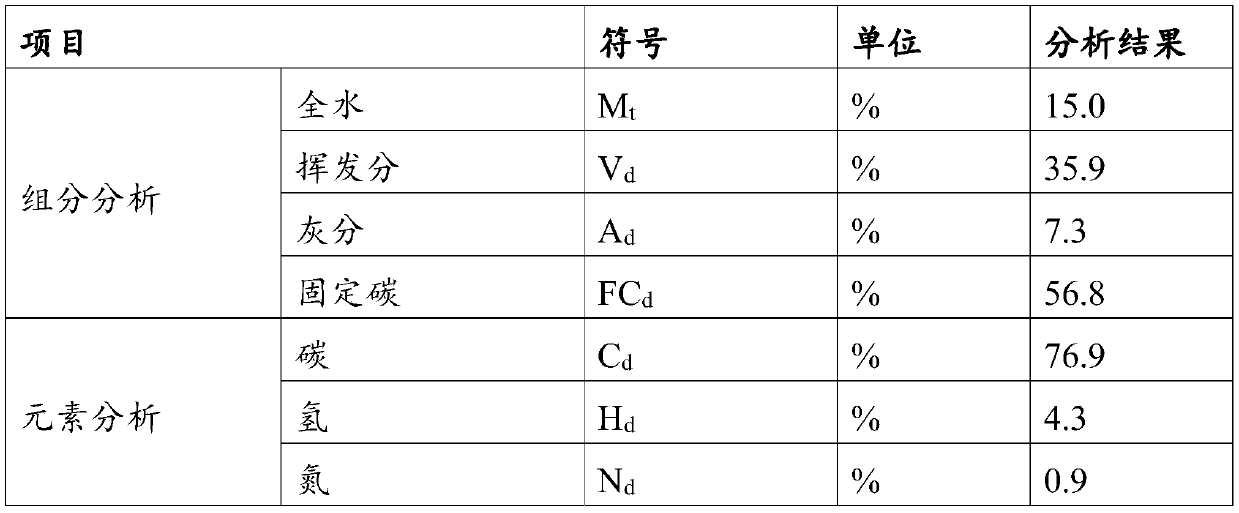

[0061] Coal chemical factories use coal as raw material to produce a variety of chemicals. The coal quality data are shown in Table 1. Some raw coal is pyrolyzed to produce tar, other oil products and coke powder, and some raw coal is produced through coal gasification to produce syngas for downstream synthesis of other chemicals. The wastewater discharged from tar wastewater has high COD and ammonia nitrogen content (see Table 2 for water quality), and contains ammonia nitrogen, phenols, indole, quinoline and other monocyclic or polycyclic aromatic compounds, as well as heterocyclic organic compounds containing nitrogen, sulfur, and oxygen. One of the most difficult wastewater to treat.

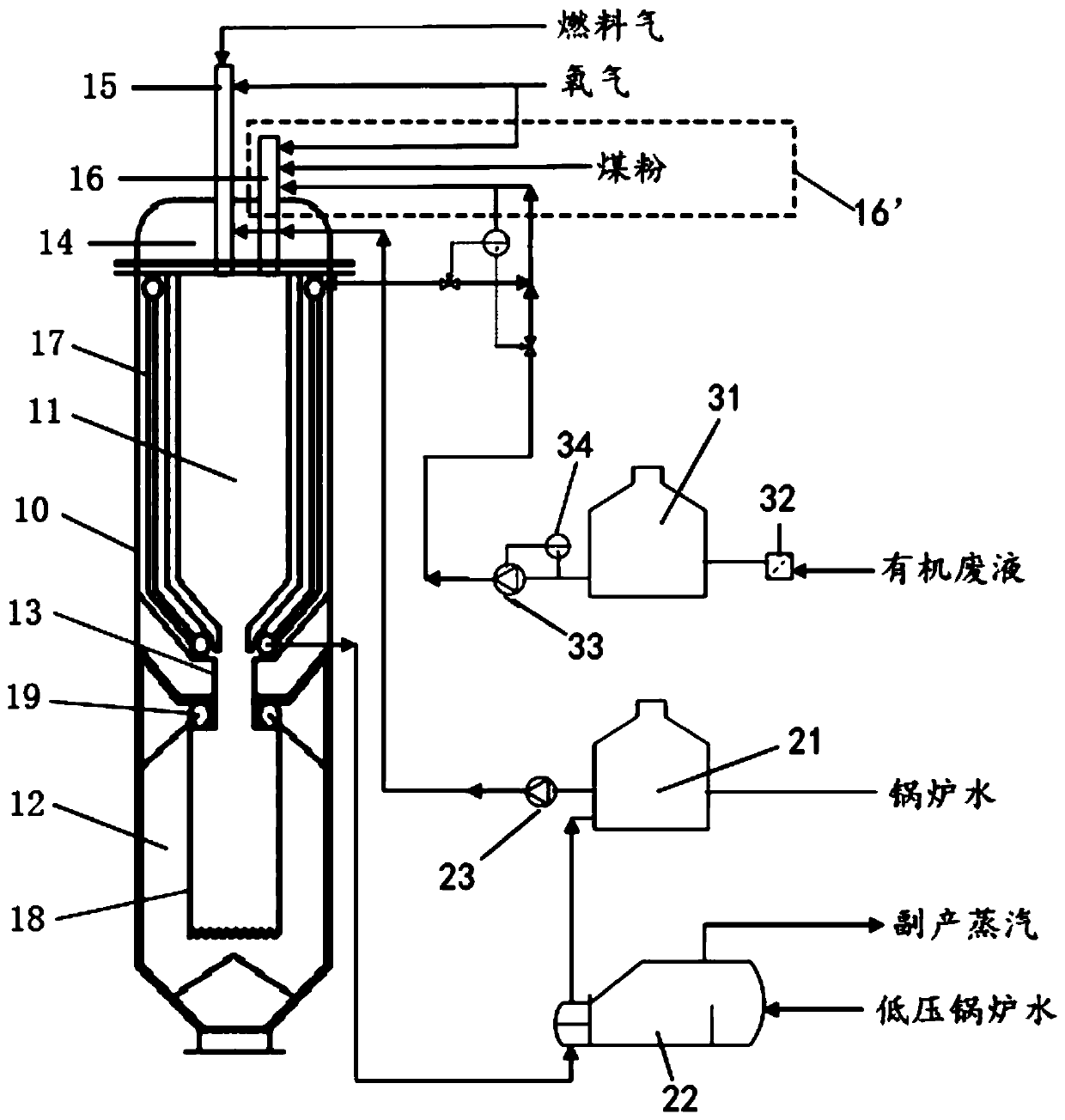

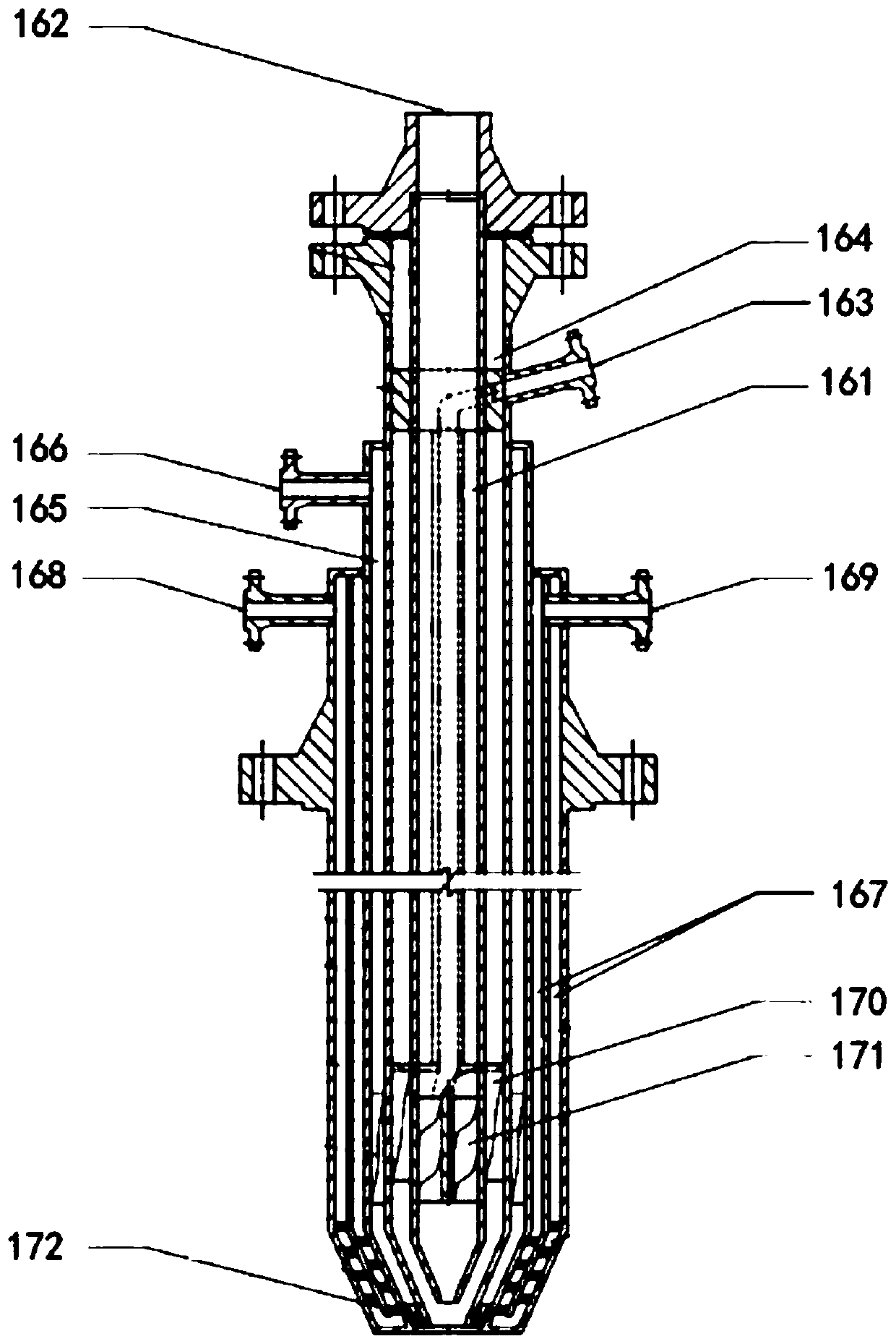

[0062] The gasification device in the plant adopts multiple above-mentioned pulverized coal pressurized gasification equipment, taking a single gasification equipment with a coal input capacity of 1,500 tons as an example, such as figure 1 and 2As shown, top-mounted 3+1 burners are used, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com