Preparation method of sodium-ion battery negative electrode material

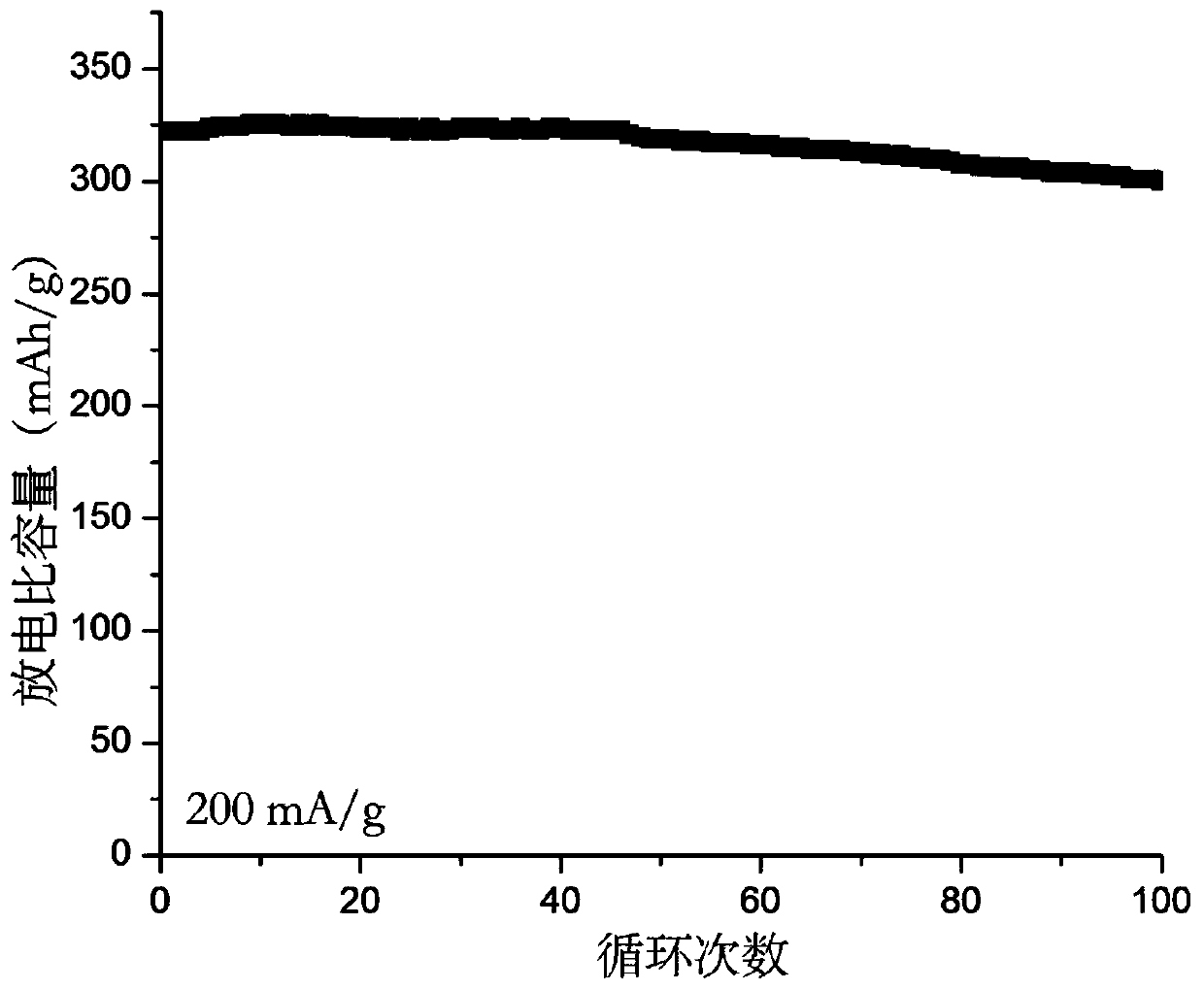

A technology for sodium ion batteries and negative electrode materials, applied in the field of material chemistry, can solve the problems of low discharge specific capacity and poor cycle stability of sodium ion batteries, and achieve the effects of improving structural stability, reducing loss and alleviating volume expansion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The first step is to prepare Ni-BTC material:

[0021] Mix 20mL deionized water, 20mL absolute ethanol, 20mL N, N dimethylformamide according to volume ratio 1:1:1, add 0.6g nickel nitrate, 0.4g trimesic acid, 2.5g polyvinylpyrrolidone, stir 0.5h, ultrasonic 0.5h. After the completion, it was transferred to a polytetrafluoroethylene-lined stainless steel reaction kettle, and kept at 180°C for 18 hours. After the reaction was completed, the product was collected, washed with methanol three times, and then dried to obtain a Ni-BTC material.

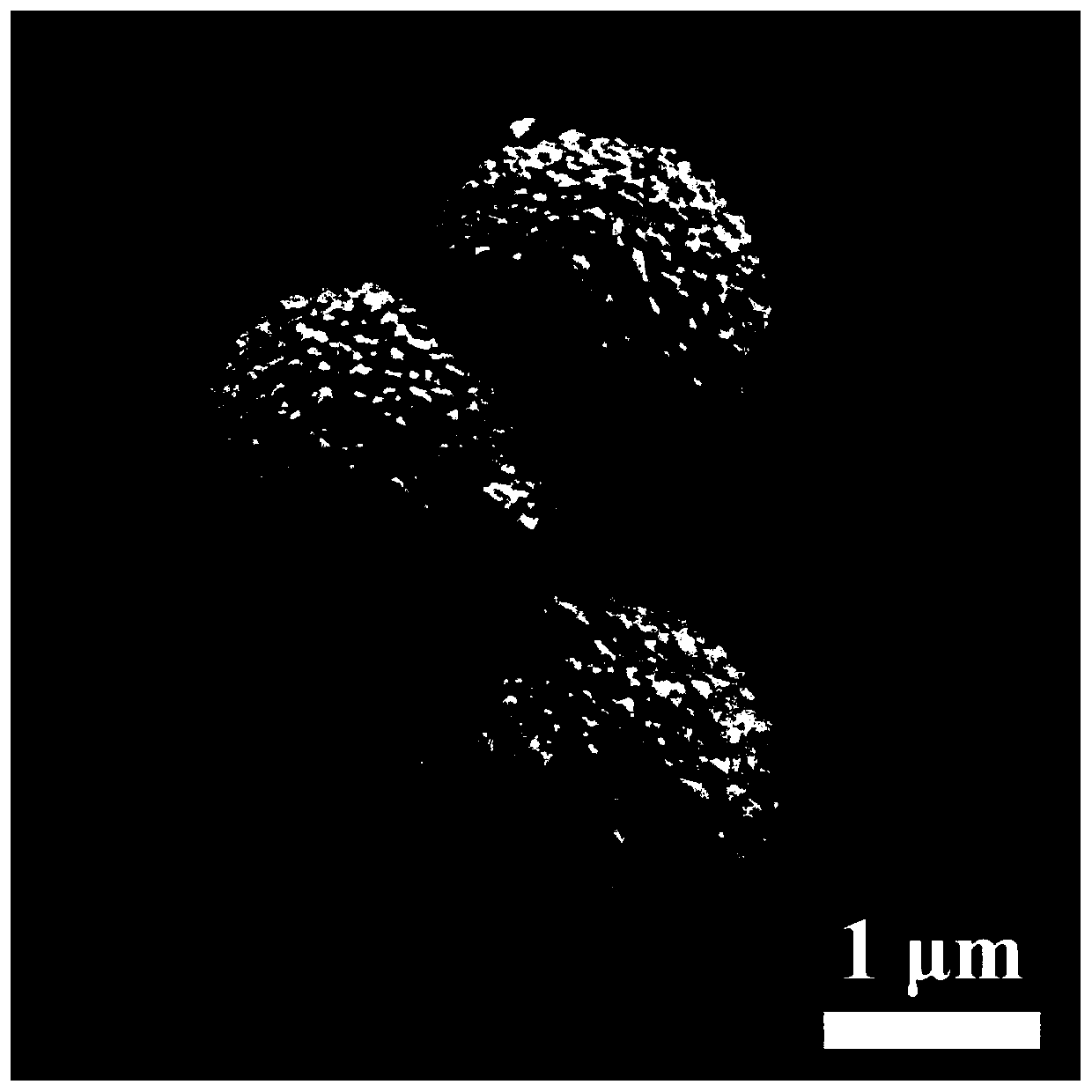

[0022] The second step is to prepare NiSe / NiO material:

[0023] Mix 0.8g of Ni-BTC prepared in the first step with 0.3g of elemental selenium powder and grind evenly, place in a tube furnace, raise the temperature to 400°C at a heating rate of 2°C / min under an argon atmosphere, and keep it for 5h. After cooling with the furnace, the NiSe / NiO material is obtained.

Embodiment 2

[0025] The first step is to prepare Ni-BTC material:

[0026] Mix 15mL deionized water, 15mL absolute ethanol, 15mL N, N dimethylformamide according to volume ratio 1:1:1, add 0.5g nickel nitrate, 0.3g trimesic acid, 2g polyvinylpyrrolidone, stir for 0.5 h, ultrasonic 0.5h. After the completion, it was transferred to a polytetrafluoroethylene-lined stainless steel reactor, and kept at 160 degrees Celsius for 12 hours. After the reaction was completed, the product was collected, washed with methanol three times, and then dried to obtain a Ni-BTC material.

[0027] The second step is to prepare NiSe / NiO material:

[0028] Mix 0.5g of the Ni-BTC material prepared in the first step with 0.2g of elemental selenium powder and grind it evenly, place it in a tube furnace, raise the temperature to 300°C at a rate of 1°C / min under an argon atmosphere, and keep it for 3h , and then cooled to obtain the NiSe / NiO material

Embodiment 3

[0030] The first step is to prepare Ni-BTC material:

[0031] Mix 30mL of deionized water, 30mL of absolute ethanol, and 30mL of N,N dimethylformamide according to the volume ratio of 1:1:3, add 1g of nickel nitrate, 0.6g of trimesic acid, and 3g of polyvinylpyrrolidone, and stir for 1h. After ultrasonication for 1 h, the product was transferred to a polytetrafluoroethylene-lined stainless steel reactor, kept at 200°C for 24 h, the product was collected, washed with methanol three times, and then dried to obtain Ni-BTC material.

[0032] The second step is to prepare NiSe / NiO material:

[0033] Mix 1 g of the Ni-BTC material prepared in the first step with 0.5 g of elemental selenium powder and grind it evenly, place it in a tube furnace, raise the temperature to 500 °C at a heating rate of 5 °C / min under an argon atmosphere, and keep it for 6 hours. After cooling, the NiSe / NiO material is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com