Flexible self-supporting composite electrode and preparation method and application thereof

A composite electrode and self-supporting technology, applied in the field of energy and materials, can solve the problems of unfavorable loading content of sulfur active substances, limited specific surface area, limited capacity, etc., and achieve the effects of reduced loss, simple preparation method, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

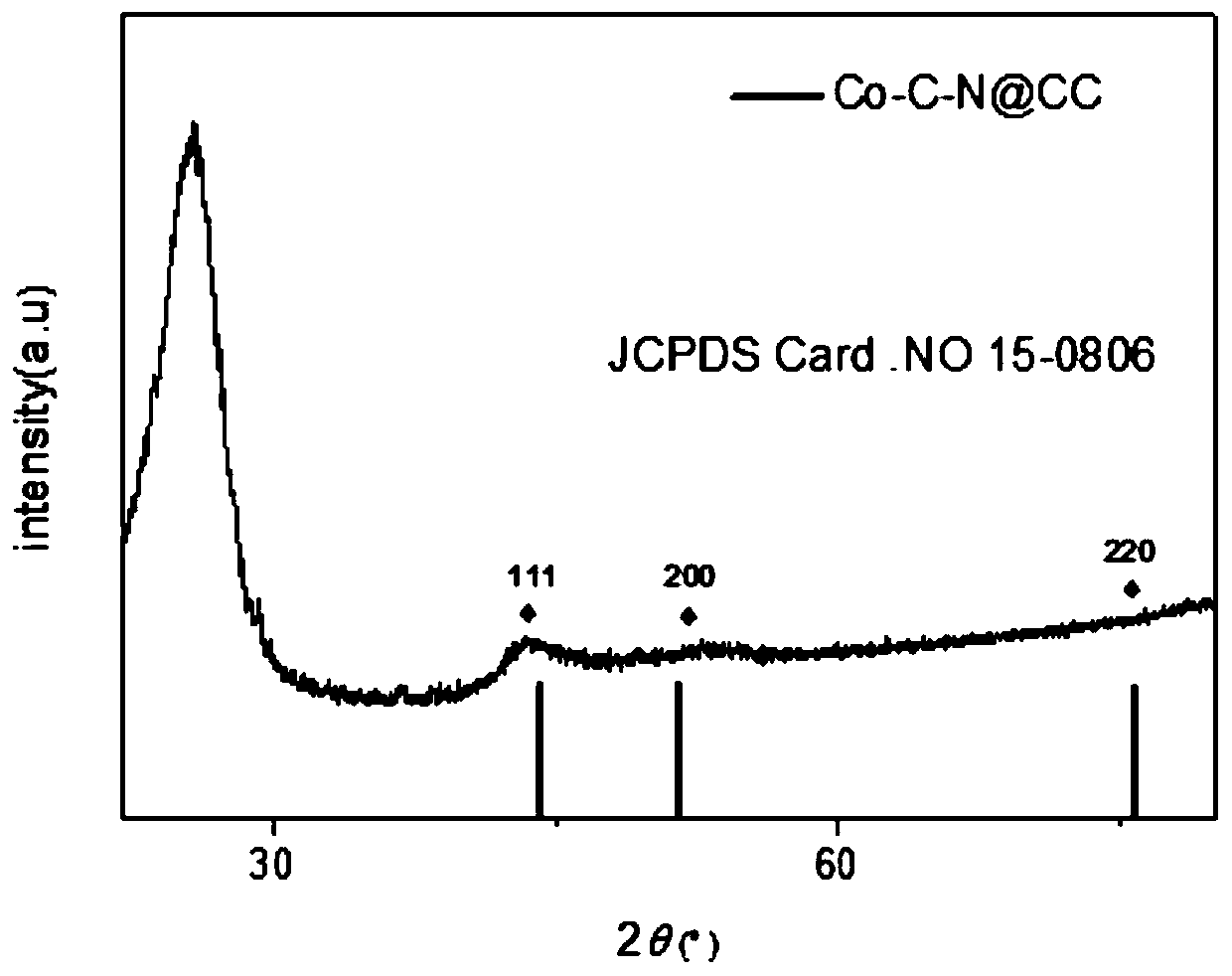

[0034] Dissolve 1.3136g of 2-methylimidazole in 40mL of deionized water and stir magnetically for 30min to obtain a 2-methylimidazole solution; dissolve 0.5821g of cobalt nitrate hexahydrate in 40mL of deionized water and stir magnetically for 30min to obtain a cobalt nitrate solution. The cobalt nitrate solution and the 2-methylimidazole solution were quickly mixed and ultrasonicated for 1 min to obtain a uniformly mixed solution. Fix the carbon cloth on the glass slide, place it in the above mixed solution and let it stand for 2h. The carbon cloth was taken out, rinsed with deionized water, and dried at 60°C for 24 hours to obtain a precursor grown on the carbon cloth in the form of a nanosheet array.

[0035] Place the carbon cloth grown with the precursor in a tube furnace at 10% H 2 / Ar atmosphere, the temperature was first raised to 350°C at a heating rate of 2°C / min, then raised to 850°C at a heating rate of 5°C / min and kept for 2 hours, and finally cooled to 500°C at ...

Embodiment 2

[0041] Dissolve 1.3136g of 2-methylimidazole in 40mL of deionized water and stir magnetically for 30min to obtain a 2-methylimidazole solution; dissolve 0.5821g of cobalt nitrate hexahydrate in 40mL of deionized water and stir magnetically for 30min to obtain a cobalt nitrate solution. The cobalt nitrate solution and the 2-methylimidazole solution were quickly mixed and ultrasonicated for 1 min to obtain a uniformly mixed solution. The graphene foam was fixed on a glass slide, and placed in the above mixed solution for 4 h. Then the graphene foam was taken out, rinsed with deionized water, and dried at 60°C for 24 hours to obtain a precursor grown on the graphene foam in the form of a nanosheet array.

[0042] The graphene foam grown with the precursor was placed in a tube furnace under 10% H 2 / Ar atmosphere, the temperature was first raised to 300°C at a heating rate of 1°C / min, then raised to 900°C at a heating rate of 5°C / min, kept for 1.5 hours, and finally cooled to 500...

Embodiment 3

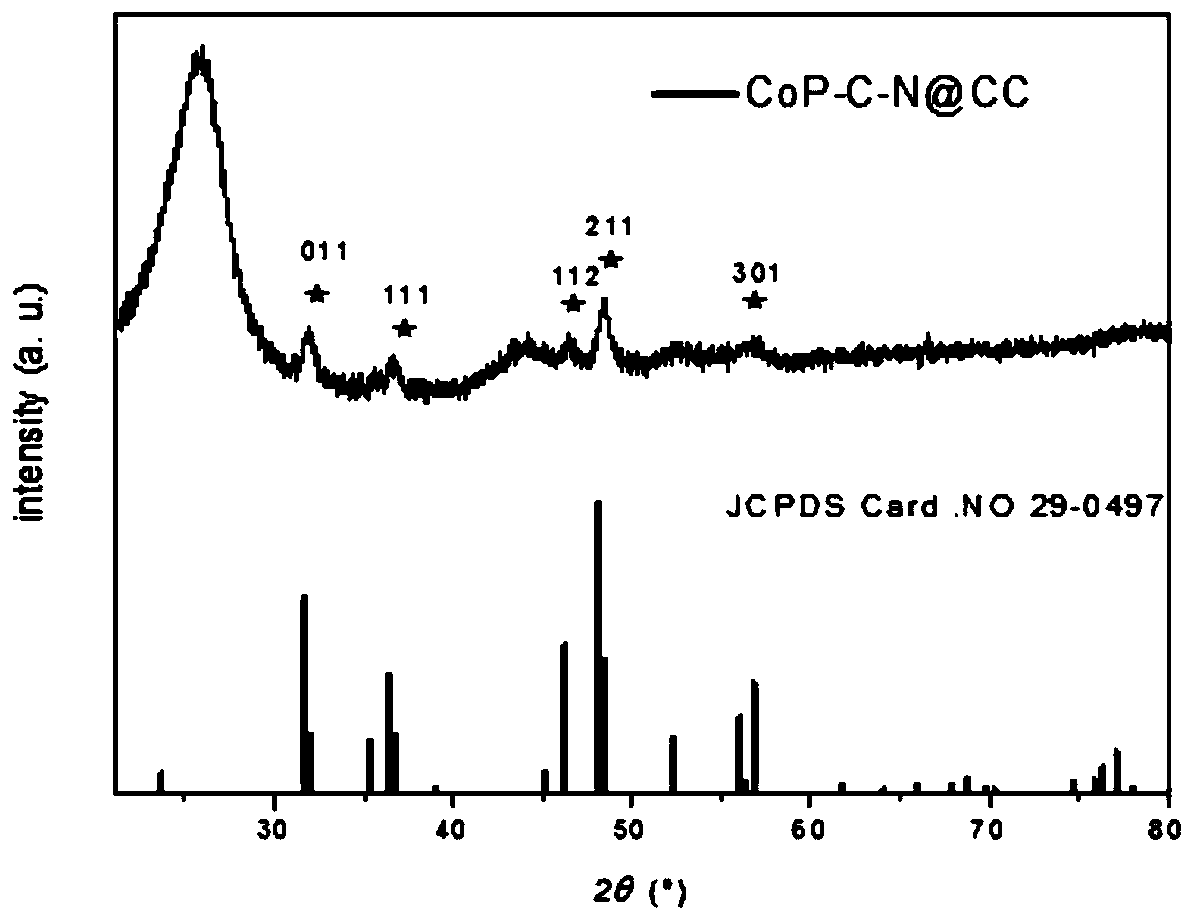

[0047] Dissolve 1.3136g of 2-methylimidazole in 40mL of deionized water and stir magnetically for 30min to obtain a 2-methylimidazole solution; dissolve 0.5821g of cobalt nitrate hexahydrate in 40mL of deionized water and stir magnetically for 30min to obtain a cobalt nitrate solution. The cobalt nitrate solution and the 2-methylimidazole solution were quickly mixed and ultrasonicated for 1 min to obtain a uniformly mixed solution. Fix the carbon cloth on the glass slide, place it in the above mixed solution and let it stand for 1h. Then the carbon cloth was taken out, rinsed with deionized water, and dried at 60 °C for 24 h to obtain a precursor grown on the carbon cloth in the form of a nanosheet array.

[0048] Place the carbon cloth grown with the precursor in a tube furnace at 10% H 2 / Ar atmosphere, first raise the temperature to 350°C at a heating rate of 2°C / min, then raise the temperature to 850°C at a heating rate of 5°C / min, keep the temperature for 2 hours, and fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com