Preparation method of metaphosphate-containing lithium ion battery positive electrode material

A lithium metaphosphate and ion battery technology, applied in battery electrodes, positive electrodes, secondary batteries, etc., can solve the problems of difficult control of material uniformity, limited performance of positive electrode materials, capacity decay, etc., to improve cycle performance and safety Performance, solution to uneven response, and the effect of inhibiting structural decay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] 1g Zn(H 2 PO 4 ) 2 (particle size 100-200nm) with 200g LiNi 0.6 co 0.2 mn 0.2 o 2 Add it into the ball mill jar, weigh the agate balls according to the ball-to-material ratio of 1:1, and then ball mill them at 500rpm for 3h. The ball-milled powder was calcined at 600°C for 5 hours in an oxygen-filled furnace to obtain Zn(PO 3 ) 2 Coated NCM622 cathode material.

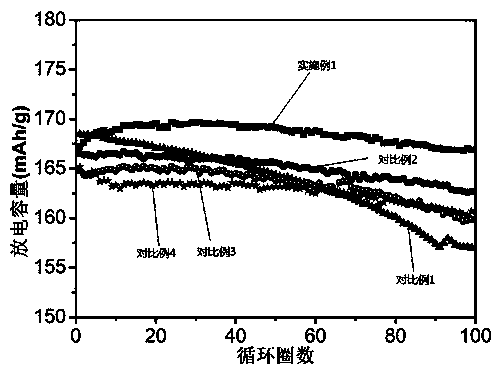

[0050] The material obtained in Example 1 has a capacity of 166.89mA·h / g after 100 cycles at 1C, and the cycle retention rate is 99.81%.

[0051] The material obtained in Example 1 is made into a positive electrode of a lithium ion battery, packed into a half cell, and tested for 100 cycles of electrochemical performance at 2.8-4.3 V, 1C, and the results are as follows: figure 2 shown.

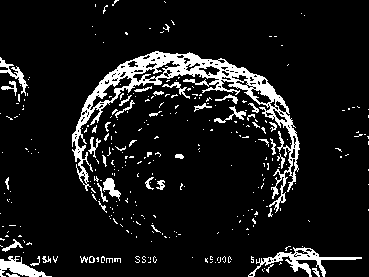

[0052] The scanning electron microscope picture of the positive electrode material containing metaphosphate lithium ion battery that embodiment 1 makes figure 1 shown.

Embodiment 2

[0054] 0.2gAl(H 2 PO 4 ) 3 and 1gZn(H 2 PO 4 ) 2 (particle size 20-50nm) with 200gLiNi 0.6 co 0.2 mn 0.2 o 2 Add it into the ball mill jar, weigh the agate balls according to the ball-to-material ratio of 2:1, and then ball mill them at 400rpm for 4h. The ball-milled powder was calcined at 500°C for 5 hours in an oxygen-filled furnace to obtain Al(PO 3 ) 3 and Zn(PO 3 ) 2 Co-coated NCM622 cathode material.

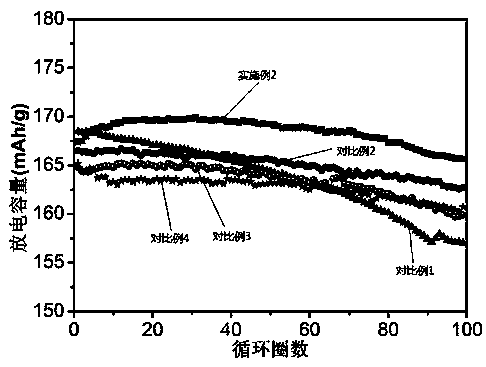

[0055] The material obtained in Example 2 is made into a positive electrode of a lithium ion battery, packed into a half cell, and tested for 100 cycles of electrochemical performance at 2.8-4.3 V, 1C, and the results are as follows: image 3 shown.

[0056] The capacity of material 1C obtained in Example 2 was 165.63 mA·h / g after 100 cycles, and the cycle retention rate was 98.94%.

Embodiment 3

[0058] 10g Al(H 2 PO 4 ) 3 (particle size 50-150nm) with 2000g LiNi 0.6 co 0.2 mn 0.2 o 2 Add it to the mixer and mix for 40min at 1000rpm. The mechanically mixed powder was calcined in an oxygen-filled furnace at 550 °C for 3 h to obtain Al(PO 3 ) 3 Coated NCM622 cathode material.

[0059] The material obtained in Example 3 is made into a positive electrode of a lithium ion battery, packed into a half battery, and tested for 100 cycles of electrochemical performance at 2.8-4.3 V, 1C, and the results are as follows: Figure 4 shown.

[0060] The material obtained in Example 3 has a capacity of 164.54mA·h / g after 100 cycles at 1C, and the cycle retention rate is 98.35%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com