Composite solid-state electrolyte, preparation method thereof and lithium secondary solid-state battery containing composite solid-state electrolyte

A solid electrolyte, lithium secondary battery technology, applied in non-aqueous electrolyte batteries, secondary batteries, solid electrolytes, etc., can solve the problems of strict requirements, unsuitable for large-scale popularization, poor cycle stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

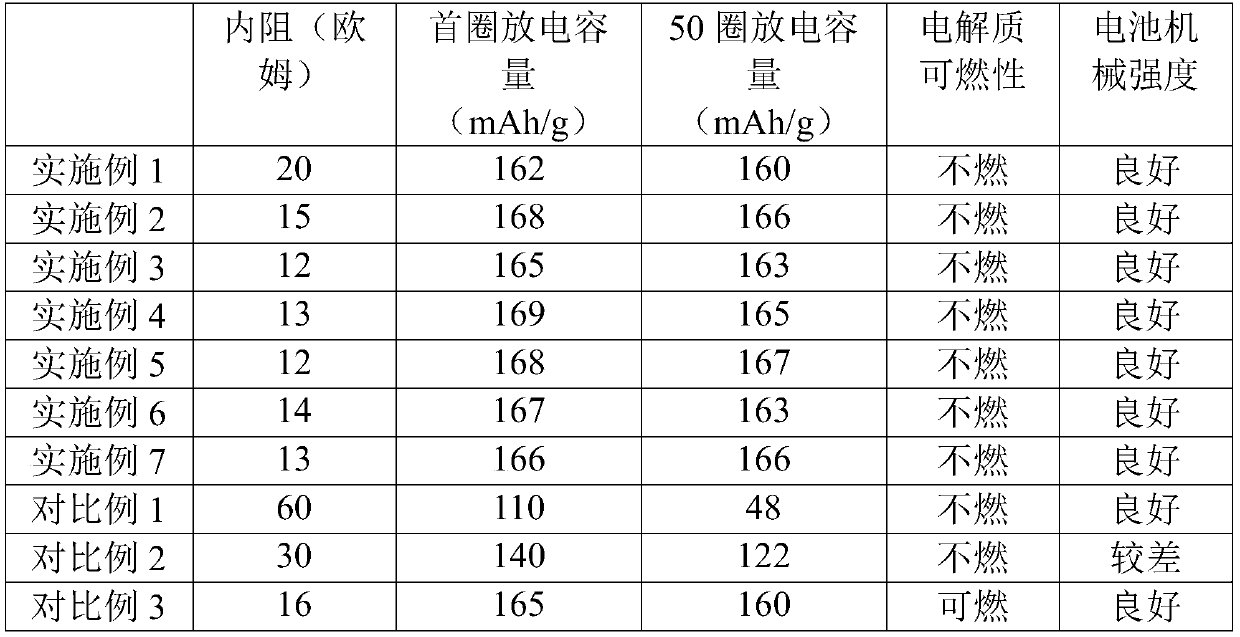

[0034] A composite solid-state electrolyte consisting of polyvinylidene fluoride (PVDF), lithium bis(trifluoromethylsulfonate)imide (LiTFSI), Li 7 La 3 Zr 2 o 12 (LLZO) and N-methyl-N-propylpiperidine bis(trifluoromethylsulfonyl)imide (PP13TFSI).

[0035] The preparation method is as follows: firstly, PVDF, LiTFSI, LLZO and PP13TFSI are dissolved in DMF solvent at a mass ratio of 20:45:5:30, stirred for 3 hours, and fully mixed to form a slurry. Finally, the slurry was cast in a tetrafluoroethylene mold and dried in vacuum at 55°C for 24 hours to obtain a composite solid electrolyte with a certain thickness. The thickness can be controlled at 150 microns by the solid content and the amount of pouring slurry.

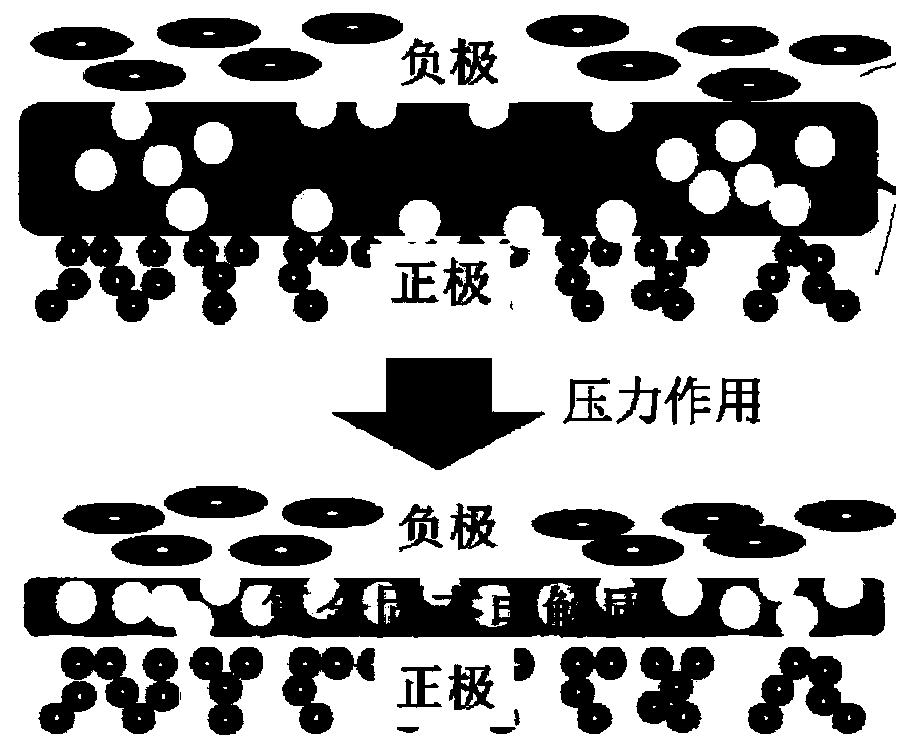

[0036] Solid-state batteries use lithium iron phosphate (LiFePO 4 ) is the positive electrode and graphite is the negative electrode. The positive and negative electrodes are made by traditional methods, but metal current collectors such as aluminum foil and copper f...

Embodiment 2

[0041] Except that the mass ratio of PVDF, LiTFSI, LLZO and PP13TFSI was 25:40:5:30, a solid-state battery was prepared and tested in the same manner as in Example 1.

Embodiment 3

[0043] In addition to using polyvinylidene fluoride-hexafluoropropylene (PVDF-HFP) instead of polyvinylidene fluoride, and making the mass ratio of PVDF-HFP: LITFSI: LLZO: PP13TFSI 35:20:5:40, in accordance with the implementation A solid-state battery was prepared and tested in the same manner as Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com