Method for separating inorganic/organic components from sludge

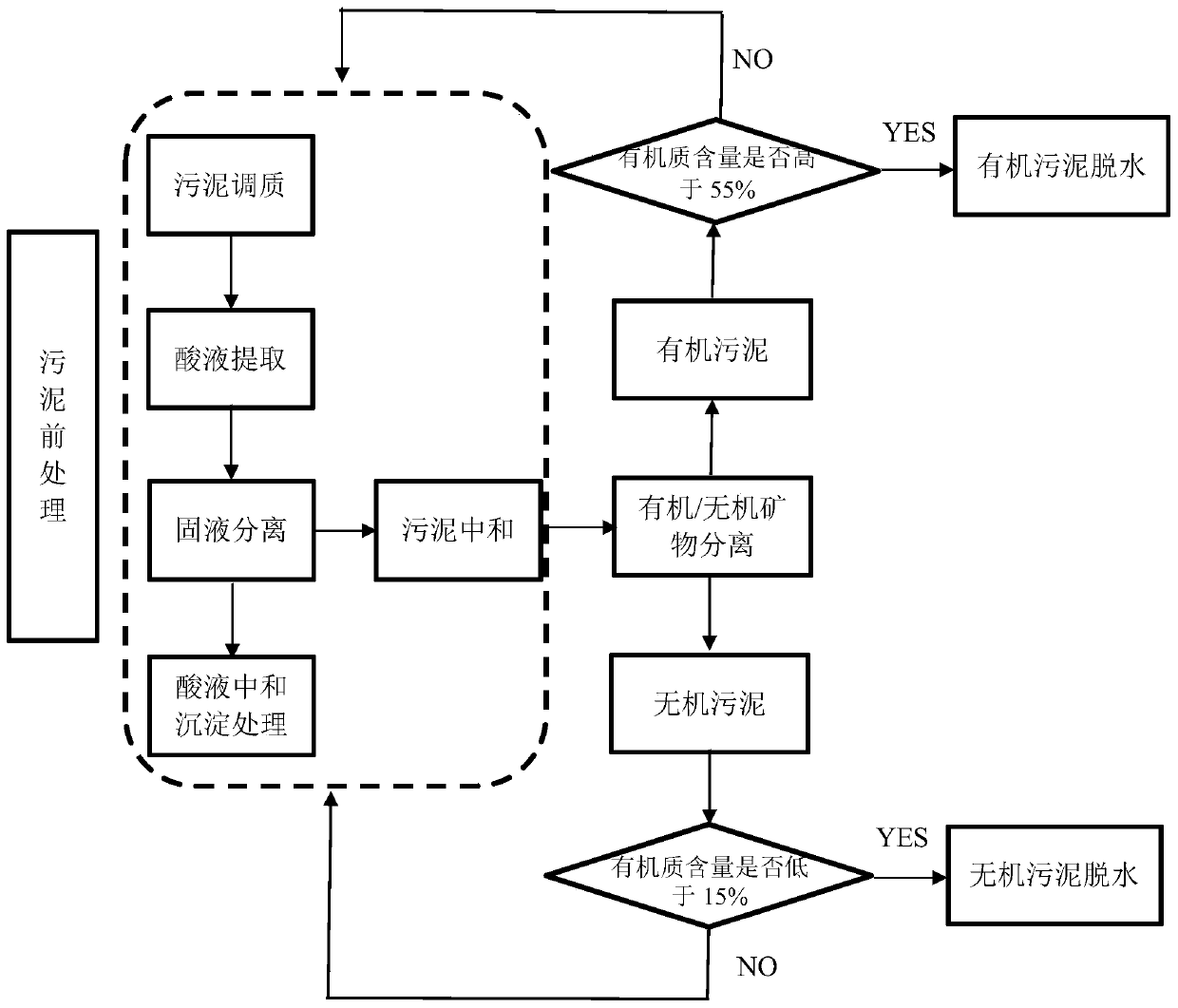

A technology of organic components and separation methods, applied in water/sludge/sewage treatment, sludge treatment, chemical instruments and methods, etc., can solve problems such as resource waste, environmental secondary pollution, and large sludge volume, and achieve improvement Separability and dehydration, easy mechanical separation, and the effect of avoiding odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The sludge was taken from the dewatered sludge and secondary sedimentation tank sludge of a municipal sewage treatment plant in Ma'anshan.

[0042] A method for separating inorganic / organic components of sludge, comprising the following processing steps:

[0043] Step 1) sludge conditioning

[0044] 11) Mix the dewatered sludge and the sludge from the secondary settling tank according to a certain ratio, and adjust the moisture content of the sludge to 94.6%;

[0045] 12) Take 500g of the above sludge and place it in a beaker, add 0.2g of potassium persulfate and 0.1g of ferrous sulfate, and fully stir and react for 30min;

[0046] 13) Add 0.5g of quicklime, fully stir and react for 30min;

[0047] 14) Heat treatment of sludge: stirring at 70°C for 30 minutes.

[0048] Step 2): acid extraction

[0049] 21) Take the above conditioned sludge and add sulfuric acid to adjust the pH to 1.5, and fully stir the reaction for 30 minutes;

[0050] 22) Centrifuge at 2000r / min...

Embodiment 2

[0060] This embodiment is a modification of embodiment 1, the difference is that step 1) heat treatment is changed to microwave treatment: 70° C., 60 min.

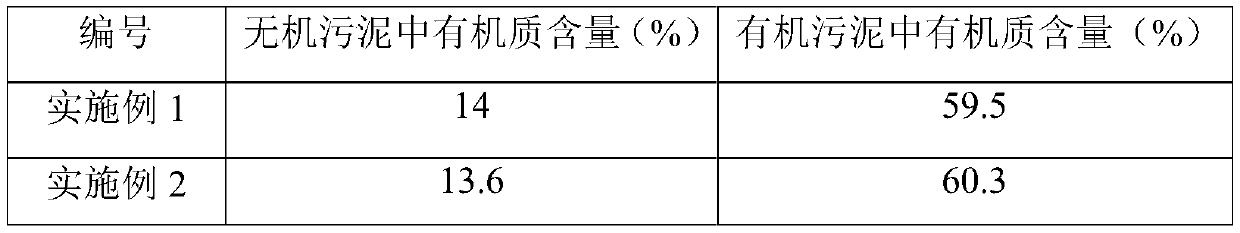

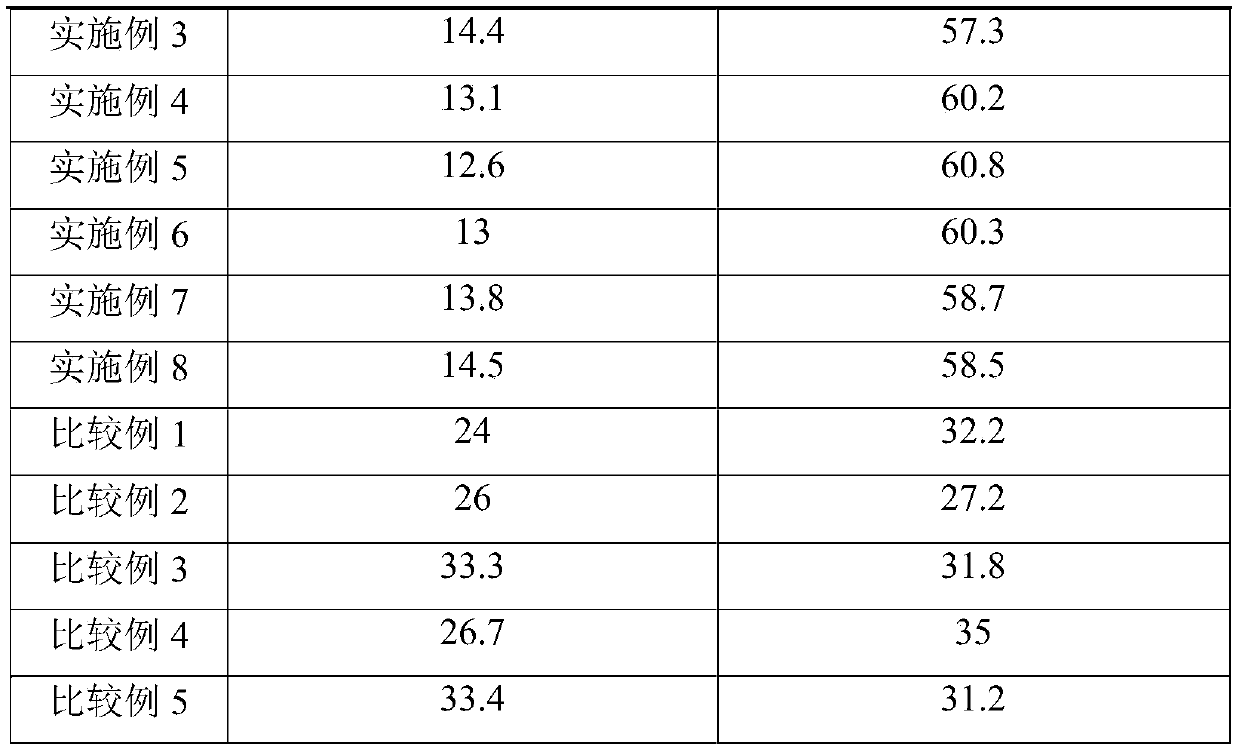

[0061] Separation of organic / inorganic minerals in sludge after primary sludge pretreatment. The organic matter content in the organic sludge and the organic matter content in the inorganic sludge were tested, and the organic matter content in the organic sludge was 46%, and the organic matter content in the inorganic sludge was 13.6%.

[0062] The organic sludge is returned to the pre-treatment of the sludge. The method is the same as above. After the secondary sludge pre-treatment, the sludge organic / inorganic minerals are separated, and the organic matter content of the separated organic sludge is tested. The results are shown in Table 1. The separated inorganic sludge Combined with the inorganic sludge separated once, the organic matter content in the inorganic sludge was tested. The results are shown in Table 1. The o...

Embodiment 3

[0064] This embodiment is a modification of Embodiment 1, and the difference is that step 1) heat treatment is changed to ultrasonic treatment: 40 kHz, 60 s.

[0065] Separation of organic / inorganic minerals in sludge after primary sludge pretreatment. The organic matter content in the organic sludge and the organic matter content in the inorganic sludge were tested, and the organic matter content in the organic sludge was 56%, and the organic matter content in the inorganic sludge was 25%.

[0066] Inorganic sludge is returned to sludge pretreatment, the method is the same as above, after secondary sludge pretreatment, sludge organic / inorganic minerals are separated, and the organic matter content of the separated inorganic sludge is tested. The results are shown in Table 1. The separated organic sludge Combined with the organic sludge separated once, the organic matter content in the organic sludge was tested. The results are shown in Table 1. The organic matter content in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com