Preparation method and application of ultraviolet-cured hyaluronic acid hydrogel with adjustable crosslinking degree

A technology of hyaluronic acid and hydrogel, applied in medical science, prosthesis, etc., can solve the problems of slow polymerization of biomass hydrogel, small molecule residue, difficult to remove, etc., and achieve controllable water absorption rate and strength, Good biocompatibility and controllable cross-linking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

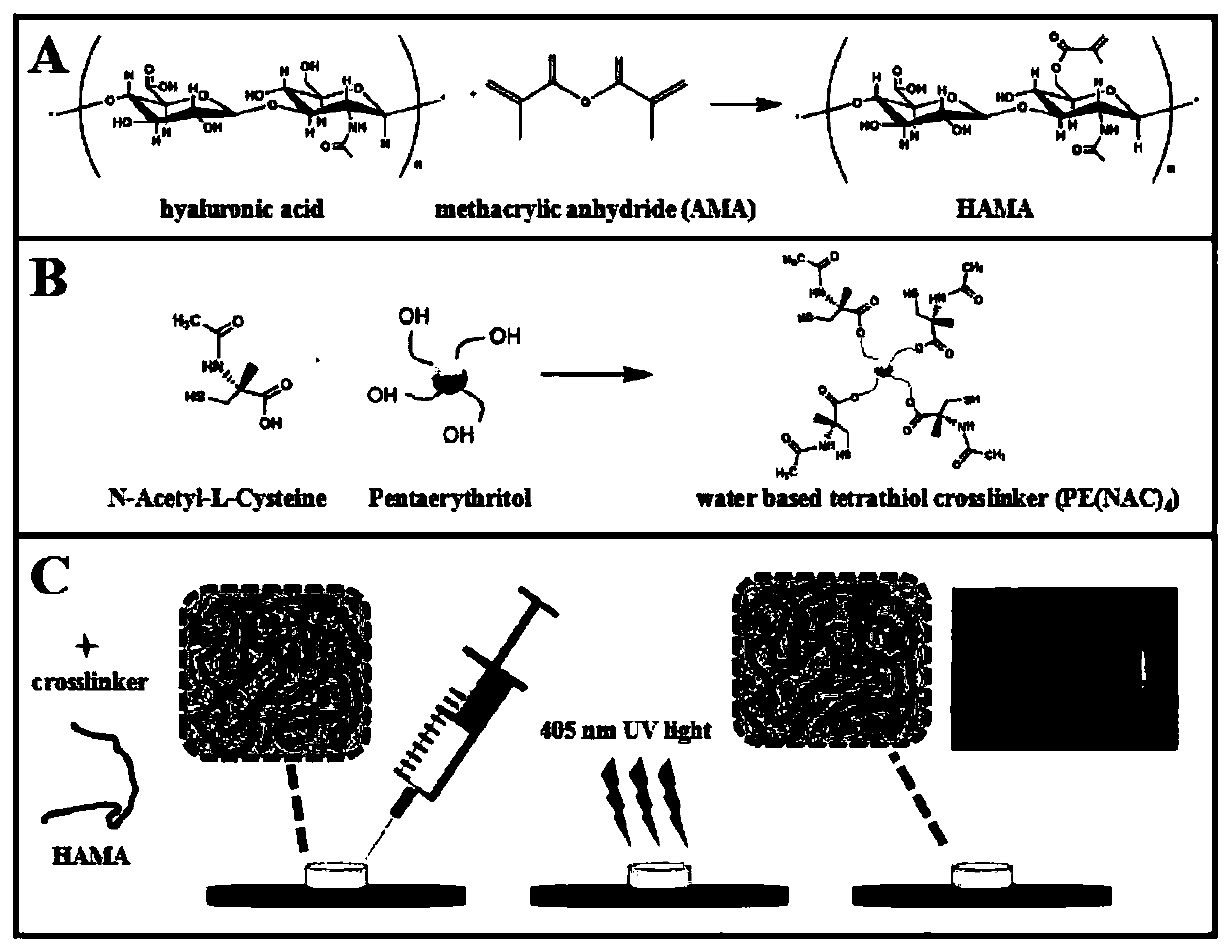

[0033] A preparation method of UV-curable hyaluronic acid hydrogel with adjustable crosslinking degree, said method comprising the following steps:

[0034] (1) Dissolve hyaluronic acid with a molecular weight of 100,000 in deionized water (1wt%) to form a uniform and transparent solution, add 1 volume of DMF, stir mechanically, cool to 3°C, and maintain the stirring and temperature conditions; Slowly add methacrylic anhydride with a molar ratio of 1.2 times (1 drop per second); then adjust the pH value of the mixture to 8 with 0.4M sodium hydroxide solution; after reacting for 10 hours, add 0.5M sodium chloride solid Continue stirring for 0.5h; use ethanol as a precipitating agent to obtain a white flocculated precipitate; the precipitate is washed with water and ethanol mixture (3 / 7, 1 / 4, 1 / 9 volume ratio); finally, the product is dissolved in deionized water (1wt %), dialyzed for 2 days, and freeze-dried to obtain a white spongy solid, i.e. methacrylated hyaluronic acid (HA...

Embodiment 2

[0038] A preparation method of UV-curable hyaluronic acid hydrogel with adjustable crosslinking degree, said method comprising the following steps:

[0039] (1) Dissolve hyaluronic acid with a molecular weight of 100,000 in deionized water (2wt%) to form a uniform and transparent solution, add 1.2 times the volume of DMF, stir mechanically, cool to 3.5°C, and maintain the stirring and temperature conditions; Slowly add methacrylic anhydride with a molar ratio of 1.4 times (2 drops per second); then adjust the pH value of the mixture to 8.5 with 0.5M sodium hydroxide solution; after reacting for 11 hours, add 0.5M sodium chloride solid Continue stirring for 0.8h; use ethanol as a precipitant to obtain a white flocculated precipitate; the precipitate is washed with water and ethanol mixture (3 / 7, 1 / 4, 1 / 9 volume ratio); finally, the product is dissolved in deionized water (1.5 wt%), dialyzed for 3 days, and freeze-dried to obtain a white spongy solid, i.e. methacrylated hyaluronic...

Embodiment 3

[0043] A preparation method of UV-curable hyaluronic acid hydrogel with adjustable crosslinking degree, said method comprising the following steps:

[0044] (1) Dissolve hyaluronic acid with a molecular weight of 100,000 in deionized water (3wt%) to form a uniform and transparent solution, add 1.5 times the volume of DMF, stir mechanically, cool to 4°C, and maintain the stirring and temperature conditions; Slowly add methacrylic anhydride with a molar ratio of 1.5 times (3 drops per second); then adjust the pH value of the mixture to 9 with 0.6M sodium hydroxide solution; after reacting for 12 hours, add 0.5M sodium chloride solid Continue stirring for 1h; use ethanol as a precipitant to obtain a white flocculated precipitate; the precipitate is washed with water and ethanol mixture (3 / 7, 1 / 4, 1 / 9 volume ratio); finally, the product is dissolved in deionized water (2wt% ), dialyzed for 4 days, and freeze-dried to obtain a white spongy solid, i.e. methacrylated hyaluronic acid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com