Expansive colloid based on ethylene-vinyl acetate copolymer resin matrix and preparation method thereof

A vinyl acetate copolymerization and resin technology, applied in the field of foaming materials, can solve the problems of endangering human property and life safety, unsatisfactory reinforcement effect, easy aging of EVA foaming materials, etc., and achieve good flame retardant and anti-aging effects, The raw material components are convenient and easy to obtain, and the preparation method is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

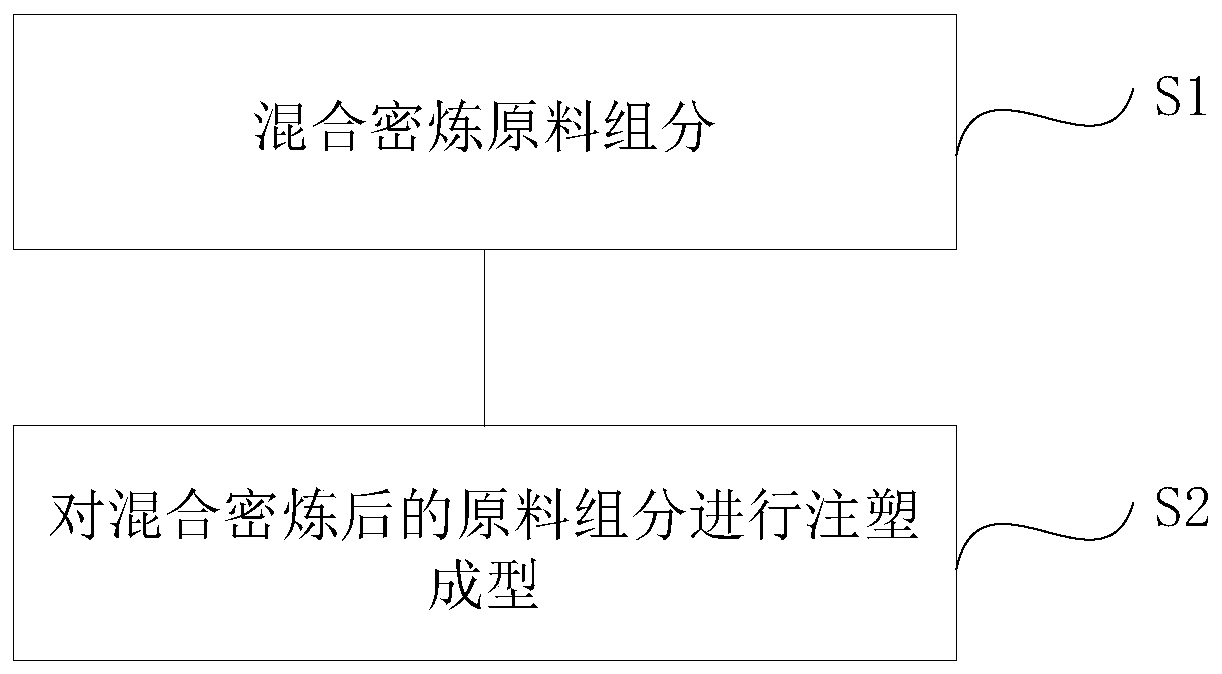

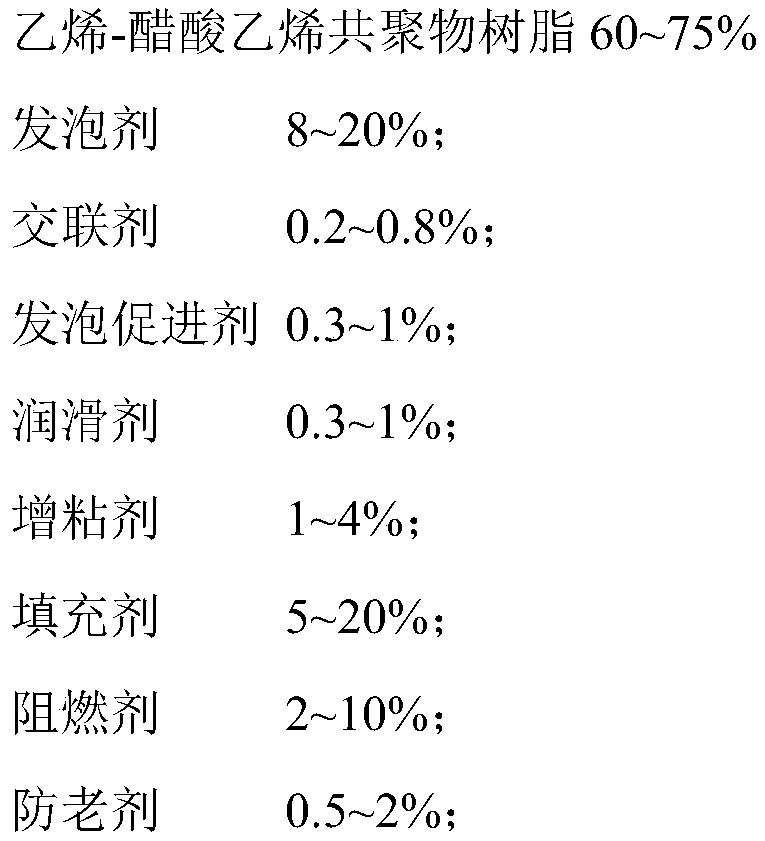

[0028] The preparation method of the expansion colloid based on the EVA resin matrix includes, step S1, the step of mixing and mixing raw material components at at least 75° C., wherein the raw material components, in terms of mass percentage, at least include: 60-75% of EVA resin ; Foaming agent 8-20%; Cross-linking agent 0.2-0.8%; Foaming accelerator 0.3-1%; Lubricant 0.3-1%; Tackifier 1-4%; Filler 5-20%; Flame retardant 2-10% of the anti-aging agent; 0.5-2% of the anti-aging agent; wherein, the filler is red brick powder modified by a silane coupling agent.

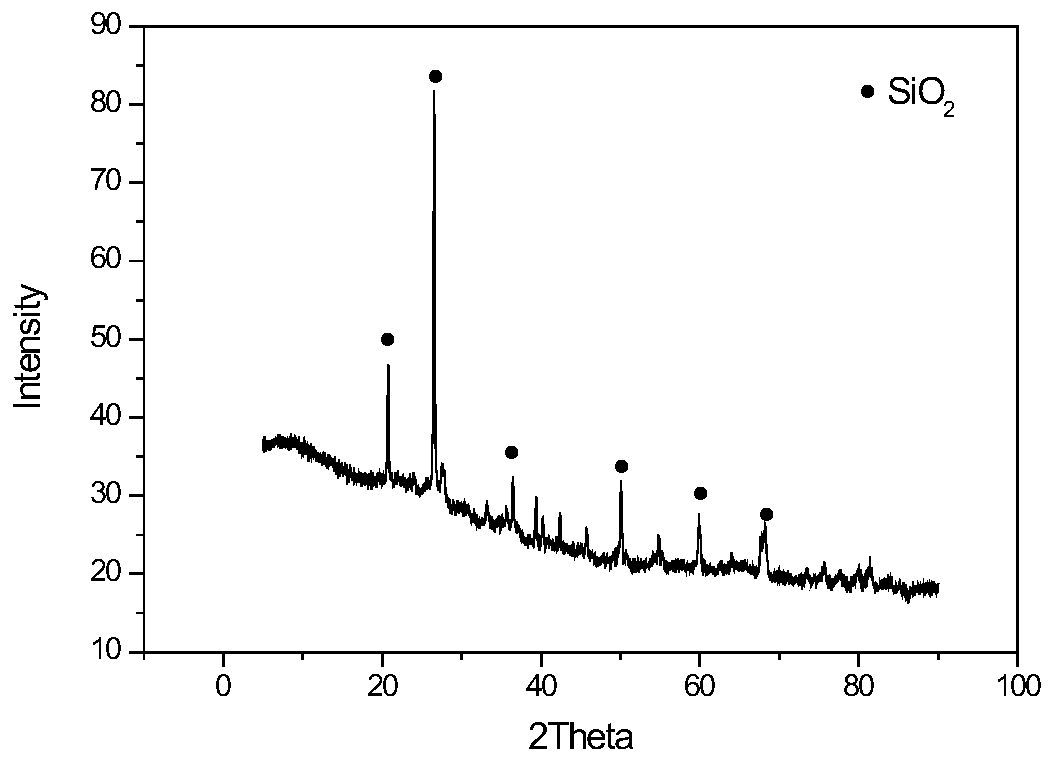

[0029] In step S1, as a filler, the red brick powder modified by the silane coupling agent is obtained, for example, by the following preparation method: ball-milling the red brick powder; using a silane coupling agent to modify the surface of the ball-milled red brick powder , to obtain red brick powder modified by silane coupling agent. Specifically, in a specific embodiment provided by the present invention, for ex...

Embodiment 1

[0037] The coarse-grained red brick powder was subjected to wet ball milling with a planetary ball mill (QM3SP04), the ball-to-material ratio was 2:1, and the ball milling time was 6h. Then use silane coupling agent KH550 to modify the surface of the ball-milled red brick powder, prepare an ethanol / water solution with a volume ratio of 1:1, weigh a certain mass of brick powder, mix 2% brick powder by mass of silane coupling agent The joint agent KH550 was slowly added to the solution, and the brick powder was added after proper stirring, and the modified red brick powder was obtained after stirring at a constant temperature in a 40°C water bath for 1 hour and drying;

[0038] Turn on the internal mixer for preheating, the temperature is 80 ° C, and when the temperature reaches, 71 parts of EVA resin (the content of vinyl acetate copolymer is 25-28%); 0.5 part of stearic acid; 10 parts of AC foaming agent; 0.5 parts of zinc oxide; 1.5 parts of C5 petroleum resin; 1 part of RD a...

Embodiment 2

[0040] Ball milling and modification process are identical with embodiment one, banburying formula and technology are as follows: open banbury mixer and carry out preheating, and temperature is 80 ℃, when temperature reaches, successively 61 parts of EVA resins (the content of vinyl acetate copolymer is 25 -28%); 0.5 part of stearic acid; 10 parts of AC foaming agent; 0.5 part of zinc oxide; 1.5 part of C5 petroleum resin; 1 part of RD antioxidant; 5 parts of hydrotalcite powder; 20 parts of modified red brick powder; BIBP0 Pour .5 parts into the 50mL mixing chamber, start the motor to drive the rotors in the mixing chamber to rotate relative to each other, and set the speed to 20r / min. After locking the device, EVA and each raw material component are mixed under the shearing action of the two rotors. uniform to obtain a mixed rubber. Then, the mixed rubber is cut into pieces and poured into an injection molding machine, and injection molding is performed at 90° C. to obtain a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com