A composite membrane comprising a decellularized amniotic membrane and a method for preparing the same

A decellularized and composite membrane technology, applied in the field of biomedicine, can solve the problems of loss of amnion bioactive substances, affecting biocompatibility, and limited effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0121] The preparation and processing of embodiment 1PCL nanofiber membrane

[0122]1. Preparation of PCL nanofiber membrane: prepare 12 wt% polycaprolactone (PCL, MW 70kDa, Sigma-Aldrich) solution. Weigh a certain amount of PCL granules as required, and dissolve in a solution of dichloromethane:methanol=4:1, with a final concentration of 12%. Add PCL solution into the syringe and place a 27G needle. The entire needle tube is placed on the electric syringe pump, which is advanced with a voltage of 12kV and an injection speed of 2.5mL / h. The tinfoil ground wire receives the ejected PCL nanofibers to form a nanofiber film with a film thickness of 80 μm and an average diameter of the PCL nanofibers of 517nm (517±178nm).

[0123] Referring to the above procedure, PCL nanofibrous membranes with thicknesses of 40 μm, 80 μm and 120 μm could be prepared.

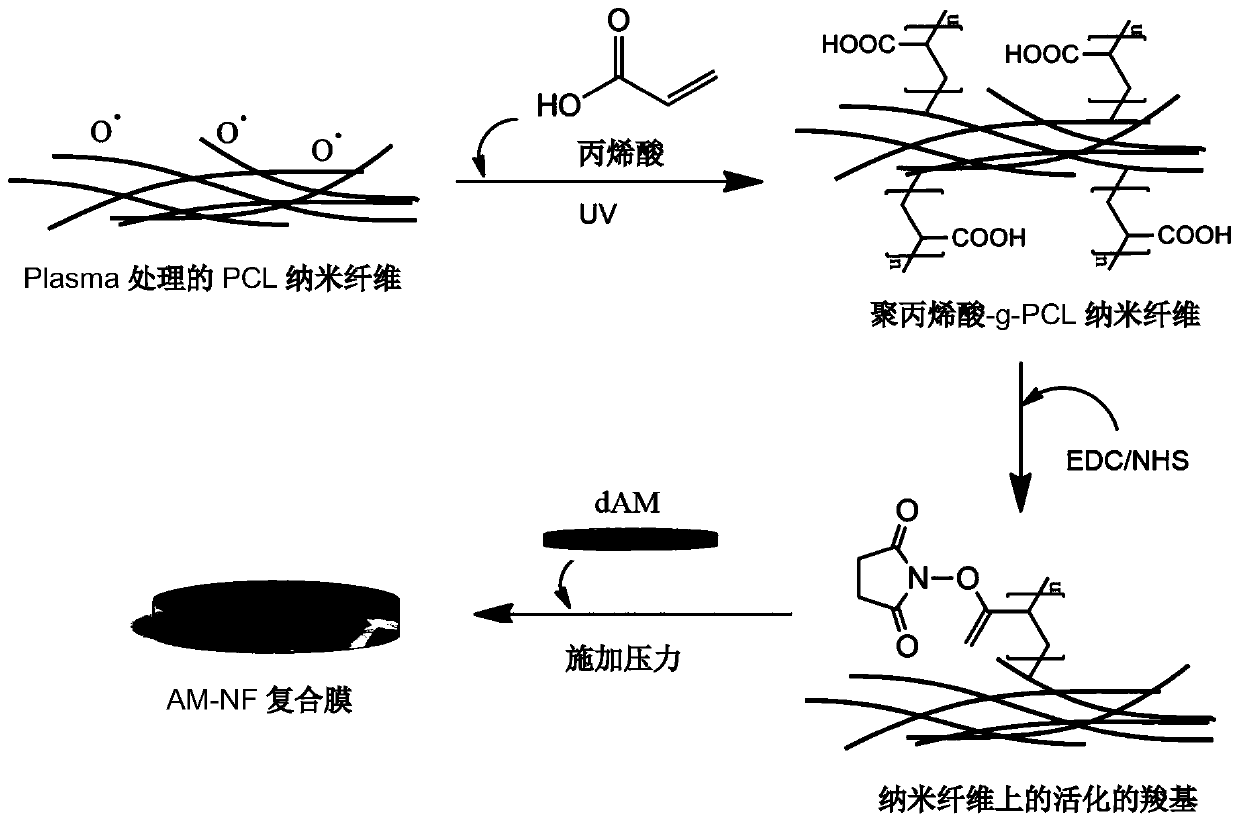

[0124] 2. Surface treatment of PCL nanofibrous membrane: the process is as follows figure 1 shown.

[0125] 1) Treat the PC...

Embodiment 2

[0131] The decellularization treatment of embodiment 2 amniotic membrane

[0132] The fresh amnion is attached to the nitrocellulose membrane with the epithelial side facing up. A 2.5% neutral protease (Dispase, Millipore) solution was prepared and dissolved in DMEM / F12 serum-free medium (Life Technology). Enzyme solution covers the surface of amniotic membrane and treats for 4 hours at 4°C. Wash 3 times with PBS. The amniotic membrane was placed in PBS solution and observed under a stereoscope. Use an iris spatula to scrape off the epithelial cells from left to right and from top to bottom. Under the microscope, white cell fragments were seen falling into the PBS solution. The amnion was washed 3 times with PBS solution.

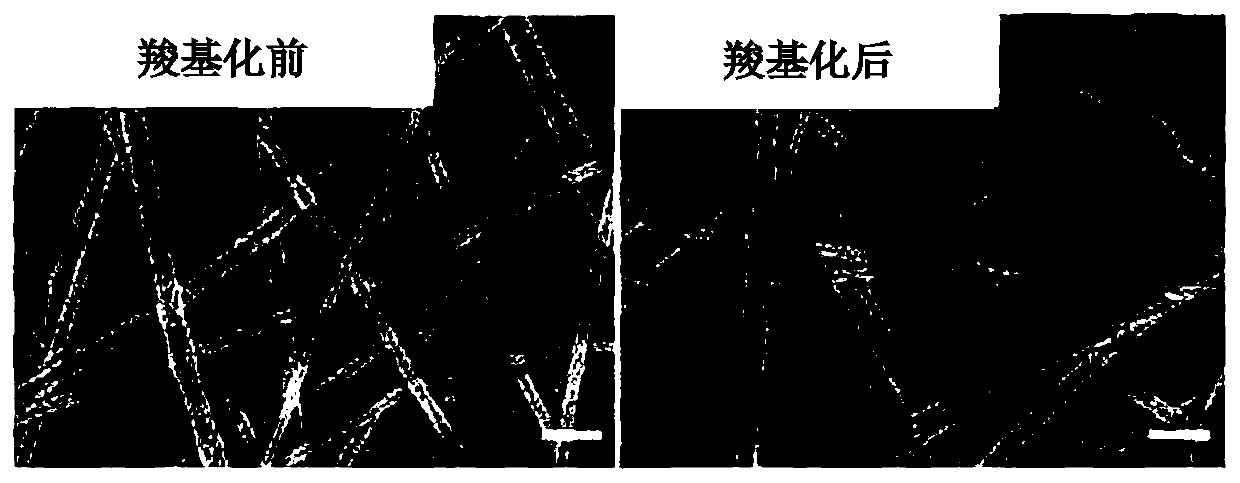

[0133] The thickness of the decellularized amniotic membrane was measured to be between 20 μm and 40 μm. The amniotic membrane before and after decellularization was observed with an optical microscope and a scanning electron microscope, and the resul...

Embodiment 3

[0136] Example 3 Preparation of decellularized amniotic membrane-PCL nanofiber composite membrane (abbreviated as "PCL-dAM composite membrane")

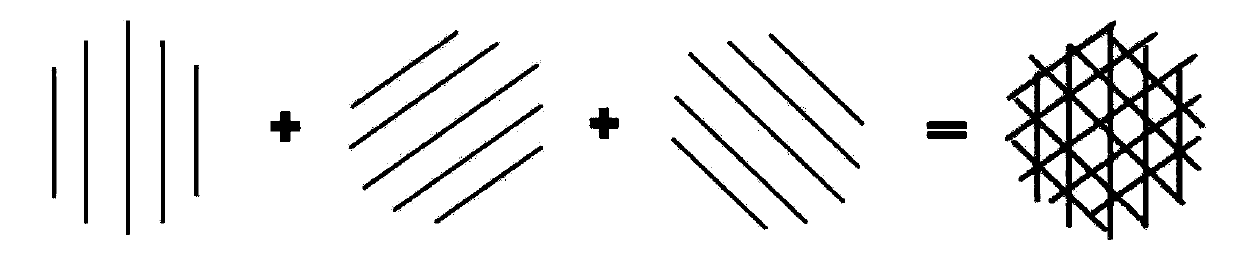

[0137] In an ultra-clean bench, wash the PCL nanofiber membrane with PBS three times. The epithelial side of the decellularized amniotic membrane is facing down, and the matrix side is facing up on a piece of Teflon (Polytetrafluoroethene, PTFE) membrane. The PCL nanofiber membrane was placed on the stromal side of the amniotic membrane. After that, another piece of Teflon membrane was placed on top of the nanofibrous membrane. Place the stacked decellularized amniotic membrane, PCL nanofiber membrane and Teflon membrane between two stainless steel plates. Place the plate in a vise. Apply 5~7MP pressure. Placed at 4°C for 12 hours. The carboxyl group on the surface of the PCL nanofiber membrane condenses with the amino group on the surface of the decellularized amniotic membrane, and the extrusion effect of the vise is used to m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com