Preparation method of high-stability self-insulation concrete block

A concrete block and self-insulation technology, which is applied in the field of building materials, can solve the problems of poor structural performance and stability of self-insulation wall materials, and achieve the effects of improving compatibility and stability, filling performance and performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

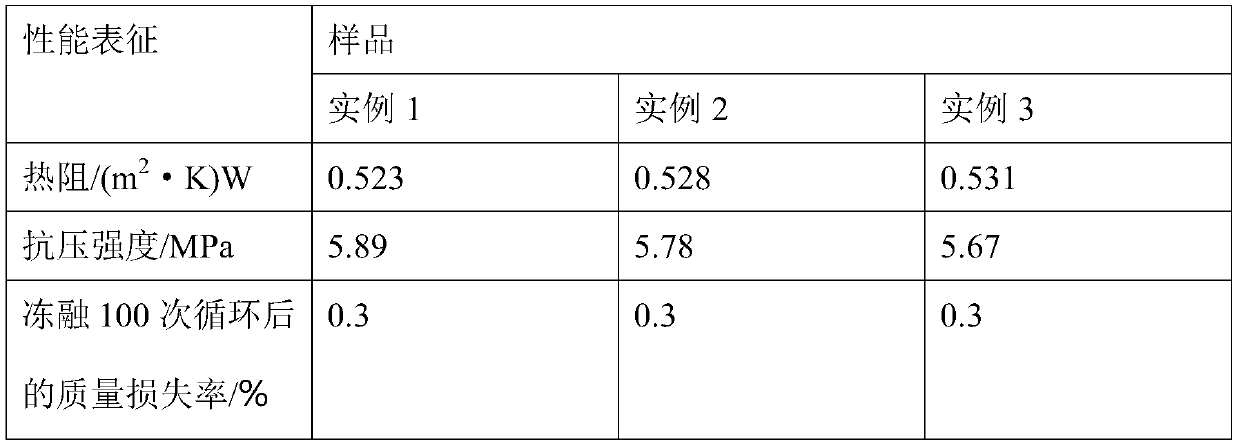

Embodiment 1

[0022] In terms of parts by weight, weigh 45 parts of deionized water, 10 parts of cetyltrimethylammonium bromide and 1 part of nano-silicon dioxide in Erlenmeyer flasks, stir and mix them, and place them at room temperature for ultrasonic dispersion for 10 minutes , to obtain a dispersion slurry; then weigh 45 parts of dispersion slurry, 10 parts of hydrogen-containing silicone oil with a viscosity of 100mm2 / s at 25°C and 3 parts of vinyl-terminated polydimethylsiloxane in parts by weight. In a three-necked flask, stir and mix and place it under 200W for ultrasonic dispersion for 10 minutes to collect the composite emulsion. According to the mass ratio of 1:5000, add the chloroplatinic acid catalyst to the composite emulsion, and then stir and mix at 5000r / min for 3 minutes, and then Stand at room temperature for 20 hours, then vacuum dry at 45°C for 3 hours to obtain dispersed particles and grind them to collect filled particles; weigh 45 parts of filled particles, 20 parts o...

Embodiment 2

[0024] In terms of parts by weight, weigh 47 parts of deionized water, 12 parts of cetyltrimethylammonium bromide and 2 parts of nano-silicon dioxide in Erlenmeyer flasks, stir and mix them, and place them at room temperature for ultrasonic dispersion for 12 minutes , to obtain a dispersion slurry; then weigh 47 parts of dispersion slurry, 12 parts of hydrogen-containing silicone oil with a viscosity of 100mm2 / s at 25°C and 4 parts of vinyl-terminated polydimethylsiloxane in parts by weight. In a three-necked flask, stir and mix and place it under 250W for ultrasonic dispersion for 12min, collect the composite emulsion, add the chloroplatinic acid catalyst to the composite emulsion according to the mass ratio of 1:5000, and then stir and mix at 7000r / min for 4min, then Stand at room temperature for 22 hours, then vacuum dry at 47°C for 4 hours to obtain dispersed particles and grind them to collect filled particles; weigh 47 parts of filled particles, 22 parts of rubber powder,...

Embodiment 3

[0026]In terms of parts by weight, weigh 50 parts of deionized water, 15 parts of cetyltrimethylammonium bromide and 2 parts of nano-silicon dioxide in Erlenmeyer flasks, stir and mix them, and place them at room temperature for ultrasonic dispersion for 15 minutes , to obtain a dispersion slurry; then weigh 50 parts of dispersion slurry, 15 parts of hydrogen-containing silicone oil with a viscosity of 100mm2 / s at 25°C and 5 parts of vinyl-terminated polydimethylsiloxane in parts by weight. In a three-neck flask, stir and mix and place it under 300W for ultrasonic dispersion for 15 minutes to collect the composite emulsion. According to the mass ratio of 1:5000, add the chloroplatinic acid catalyst to the composite emulsion, and then stir and mix at 8000r / min for 5 minutes, and then Leave to react at room temperature for 24 hours, then vacuum-dry at 50°C for 5 hours to obtain dispersed particles and grind them to collect filled particles; in parts by weight, weigh 50 parts of f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com