Method for controlling byproduct anisole in diphenyl carbonate production

A technology of diphenyl carbonate and anisole, which is applied in the field of controlling the by-product anisole of diphenyl carbonate production, can solve the problems of direct pollution discharge and the inability to effectively control the generation of by-product anisole, etc., and achieve increased revenue, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1). During the actual operation of the device, in the reaction of 3t / h dimethyl carbonate and 6.4t / h phenol in the esterification tower, the reaction temperature is controlled at 200°C, and the catalyst concentration is 80ppm-100ppm for esterification reaction to obtain MPC. MPC is disproportionated In the reaction tower, the reaction temperature is controlled at 180°C, the catalyst concentration is 750ppm-800ppm, and the residence time is controlled for 5h, and the disproportionation reaction is carried out to obtain diphenyl carbonate. At the same time, the degreasing reaction of MPC produces anisole as a by-product, and the formation rate is 50kg / h .

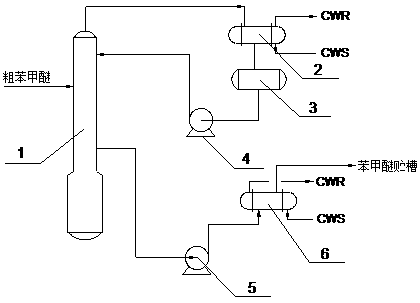

[0030] (2). The anisole waste liquid produced after the anisole mixed liquid at the top of the disproportionation reaction tower passes through the anisole removal tower of the device is sent to such as figure 1 In the shown rectification tower 1, under the pressure of 25kPa, the reflux ratio of the control tower is 1...

Embodiment 2

[0032] (1). During the actual operation of the device, in the reaction of 3t / h dimethyl carbonate and 6.4t / h phenol in the esterification tower, the reaction temperature is controlled at 200°C, and the catalyst concentration is 80ppm-100ppm for esterification reaction to obtain MPC. MPC is disproportionated In the reaction tower, the reaction temperature is controlled at 180°C, the catalyst concentration is 700ppm-750ppm, and the residence time is controlled for 5h, and the disproportionation reaction is carried out to obtain diphenyl carbonate. At the same time, the degreasing reaction of MPC produces anisole as a by-product, and the formation rate is 49kg / h .

[0033] (2). The anisole waste liquid produced after the anisole mixed liquid at the top of the disproportionation reaction tower passes through the anisole removal tower of the device is sent to such as figure 1 In the shown rectification tower 1, under the pressure of 20kPa, the reflux ratio of the control tower is 1...

Embodiment 3

[0035] (1). During the actual operation of the device, in the reaction of 3t / h dimethyl carbonate and 6.4t / h phenol in the esterification tower, the reaction temperature is controlled at 200°C, and the catalyst concentration is 80ppm-100ppm for esterification reaction to obtain MPC. MPC is disproportionated In the reaction tower, the reaction temperature is controlled at 180°C, the catalyst concentration is 730ppm-760ppm, and the residence time is controlled for 5h, and the disproportionation reaction is carried out to obtain diphenyl carbonate. At the same time, the degreasing reaction of MPC produces anisole as a by-product, and the formation rate is 51kg / h .

[0036] (2). The anisole waste liquid produced after the anisole mixed liquid at the top of the disproportionation reaction tower passes through the anisole removal tower of the device is sent to such as figure 1 In the rectification tower 1 shown, under the pressure of 28kPa, the reflux ratio of the control tower is 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com