Scratch-resistant polypropylene material and preparation method thereof

A polypropylene material and scratch-resistant technology, applied in the field of scratch-resistant polypropylene materials and their preparation, can solve the problems of general scratch resistance and achieve the effect of optimizing the overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

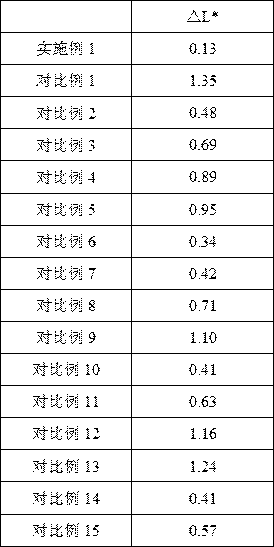

Examples

Embodiment 1

[0031] A scratch-resistant polypropylene material, consisting of 60 parts of modified polypropylene, 15 parts of composite basic flame retardant, 10 parts of composite synergistic flame retardant, 5 parts of composite lubricant, 3 parts of compatibilizer, and 5 parts of coupling agent 5 parts, 5 parts of dispersant, 2 parts of composite cross-linking agent, 2 parts of antioxidant, utilize high-speed mixer to blend, obtain by melt blending by three-screw extruder;

[0032] The mass ratio of each component of the modified polypropylene is: polypropylene: POE thermoplastic elastomer: EPDM rubber: dicumyl peroxide=89:5:5:1;

[0033] The mass ratio of each component of the composite basic flame retardant is: magnesium hydroxide: calcium carbonate: raw gypsum=2:2:1;

[0034] The mass ratio of each component of the composite lubricant is: polyethylene wax: stearic acid: paraffin wax=1:1:1;

[0035] Described compatibilizer is maleic anhydride grafted polypropylene;

[0036] The ant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com