Efficient and environmentally-friendly paint diluent and preparation method thereof

An environmentally friendly, thinner technology, applied in the direction of coating, can solve the problems of easy whitening of paint film, poor leveling, too fast drying, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

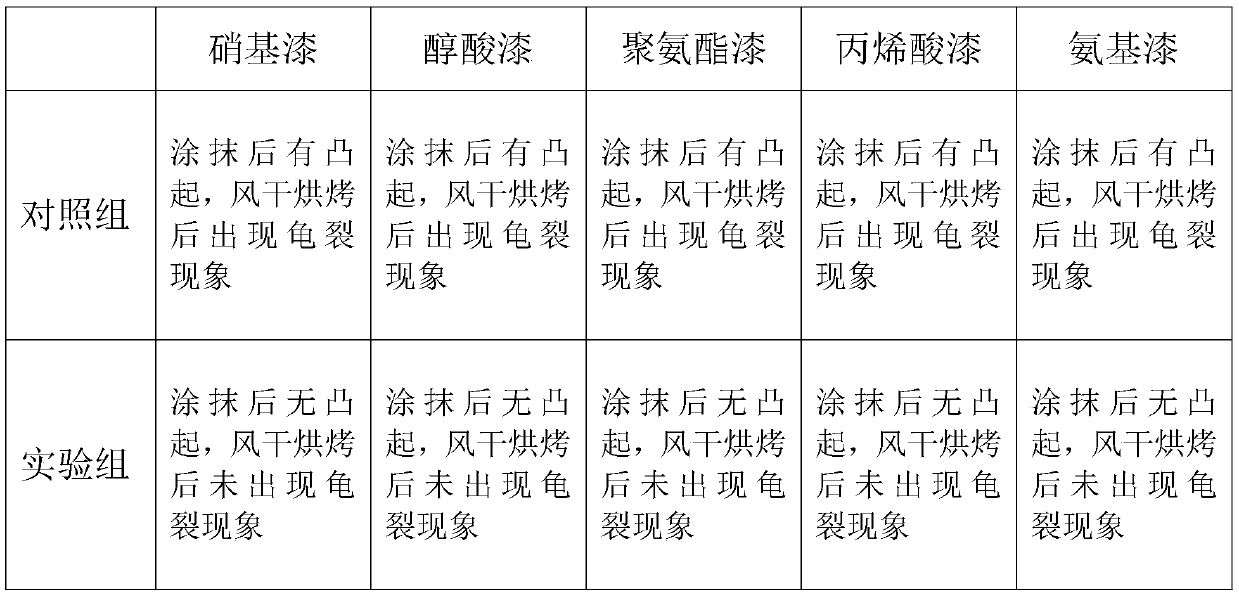

Examples

Embodiment 1

[0014] An efficient and environmentally friendly paint diluent and its preparation method, comprising the following raw materials: ethyl acetate, ethyl butyl ester, ethanol, acetone, dichloromethane, dichloroethane, ethylene glycol ethyl ether acetate, cyclohexanone, Butyl orthosilicate, ethyl cellosolve, methyl isopropyl ketone, turpentine, fragrance;

[0015] 10 parts of ethyl acetate, 10 parts of ethyl butyl ester, 25 parts of ethanol, 10 parts of acetone, 10 parts of dichloromethane, 20 parts of dichloroethane, 30 parts of ethylene glycol ethyl ether acetate, 25 parts of cyclohexanone, normal 15 parts of butyl silicate, 10 parts of ethyl cellosolve, 12 parts of methyl isopropyl ketone, 8 parts of turpentine, 1 part of fragrance;

[0016] Mix ethyl acetate, ethyl butyl ester, ethanol, acetone, dichloromethane, dichloroethane, ethylene glycol ethyl ether acetate, cyclohexanone, methyl isopropyl ketone, turpentine, and add acid-base regulator Adjust the PH value to 5, stir at 50°...

Embodiment 2

[0018] An efficient and environmentally friendly paint diluent and its preparation method, comprising the following raw materials: ethyl acetate, ethyl butyl ester, ethanol, acetone, dichloromethane, dichloroethane, ethylene glycol ethyl ether acetate, cyclohexanone, Butyl orthosilicate, ethyl cellosolve, methyl isopropyl ketone, turpentine, fragrance;

[0019] 11 parts of ethyl acetate, 14 parts of ethyl butyl ester, 26 parts of ethanol, 12 parts of acetone, 13 parts of dichloromethane, 24 parts of dichloroethane, 32 parts of ethylene glycol ethyl ether acetate, 26 parts of cyclohexanone, normal 18 parts of butyl silicate, 11 parts of ethyl cellosolve, 13 parts of methyl isopropyl ketone, 10 parts of turpentine, 2 parts of fragrance;

[0020] Mix ethyl acetate, ethyl butyl ester, ethanol, acetone, dichloromethane, dichloroethane, ethylene glycol ethyl ether acetate, cyclohexanone, methyl isopropyl ketone, turpentine, and add acid-base regulator Adjust the PH value to 5, stir at 5...

Embodiment 3

[0022] An efficient and environmentally friendly paint diluent and its preparation method, comprising the following raw materials: ethyl acetate, ethyl butyl ester, ethanol, acetone, dichloromethane, dichloroethane, ethylene glycol ethyl ether acetate, cyclohexanone, Butyl orthosilicate, ethyl cellosolve, methyl isopropyl ketone, turpentine, fragrance;

[0023] 12 parts of ethyl acetate, 18 parts of ethyl butyl ester, 27 parts of ethanol, 14 parts of acetone, 16 parts of dichloromethane, 28 parts of dichloroethane, 34 parts of ethylene glycol ethyl ether acetate, 27 parts of cyclohexanone, normal 21 parts of butyl silicate, 12 parts of ethyl cellosolve, 14 parts of methyl isopropyl ketone, 12 parts of turpentine, 3 parts of fragrance;

[0024] Mix ethyl acetate, ethyl butyl ester, ethanol, acetone, dichloromethane, dichloroethane, ethylene glycol ethyl ether acetate, cyclohexanone, methyl isopropyl ketone, turpentine, and add acid-base regulator Adjust the PH value to 5, stir at 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com